Choosing the Right PET Bottle to Fiber Recycling Line

Understanding the complexities involved in selecting a suitable PET recycling line is essential for manufacturers aiming to produce high-quality fiber from waste bottles. With capacities ranging from 1000kg/h to 6000kg/h, bottle to fiber production lines must be tailored to match throughput, input contamination levels, and end-use requirements. A properly selected PET recycling line can enhance output consistency, reduce operational costs, and improve energy efficiency. With increasing global demand for recycled polyester fiber, many recyclers are turning to advanced technologies that ensure high yield and sustainability. Choosing the right combination of washing, drying, and extrusion equipment can determine the long-term viability of the recycling plant. Each stage in the PET recycling line should be optimized to maintain quality while keeping energy and water consumption in check.

Evaluating Production Capacity and Throughput

Matching Line Capacity to Operational Goals

When considering a PET recycling line for bottle to fiber applications, one of the first factors to address is production capacity. A line with 1000kg/h capacity might suit a regional recycling center with moderate supply, while a 6000kg/h capacity setup is more appropriate for industrial-scale operations. Determining the correct size depends on feedstock availability, desired output volumes, and projected market demand. Investing in an undersized line may limit growth, while an oversized system could lead to inefficient use of resources. It's critical to balance throughput capacity with operational flexibility. Advanced PET recycling lines offer modular scalability, allowing plants to start with smaller units and expand as input volumes increase. Making capacity decisions also includes considering downstream fiber spinning needs and whether the plant operates in batch or continuous modes.

Throughput Efficiency and Material Flow Design

Throughput efficiency is more than just raw capacity; it's about how effectively the system processes PET bottles into fiber-grade flakes. Efficient material flow design minimizes downtime and bottlenecks while maximizing line speed. PET recycling line components—like shredders, float-sink tanks, and hot washers—must be integrated to avoid overloading or underutilizing specific sections. Using conveyors with variable speed drives, level sensors, and surge hoppers ensures a smooth transition of material between stages. Consistent throughput leads to stable extrusion output, which is essential in producing uniform fiber. If the recycling line is to support multiple shifts or operate continuously, smart layout planning and buffer storage options must be considered. Investing in high-speed but stable throughput machinery helps meet quality benchmarks without excessive labor or energy consumption.

Assessing Bottle to Fiber Process Requirements

Cleaning Precision for Fiber Production

The bottle to fiber process places stringent demands on cleanliness and decontamination. Unlike food-grade applications that focus on chemical purity, fiber production emphasizes clarity, color consistency, and mechanical integrity of flakes. A PET recycling line must therefore remove not only dirt and labels but also glue residues, caps, and multilayer films that could interfere with fiber extrusion. Hot caustic washing units, multiple friction washers, and sink-float separation steps are crucial. Designing the line to incorporate high-temperature washing tanks with adjustable dwell times ensures contaminants are fully eliminated. Inline water filtration, high-pressure rinsing, and pH-controlled chemical dosing systems also contribute to output quality. Clean flakes lead to fewer extrusion problems, reduced downtime, and improved spinning line performance, making a robust washing sequence indispensable.

Intrinsic Viscosity Control and Homogeneity

Fiber spinning requires PET flakes with stable intrinsic viscosity (IV) and consistent melt characteristics. The recycling line must include crystallization and solid-state polycondensation (SSP) units if the flakes are to be used directly in fiber applications without blending. IV degradation during washing and drying must be minimized, which involves precise temperature control and reduced mechanical stress. Certain drying systems, like vacuum or infrared dryers, preserve IV better than conventional hot air dryers. In cases where only mechanical recycling is performed, the PET recycling line must ensure that reprocessed flakes retain homogeneity in color and size. Pelletizing before fiber spinning can improve melt uniformity, especially for high-capacity systems above 4000kg/h. Uniform IV and color are crucial for consistent denier output and fiber tensile strength.

Evaluating Equipment Configuration and Customization

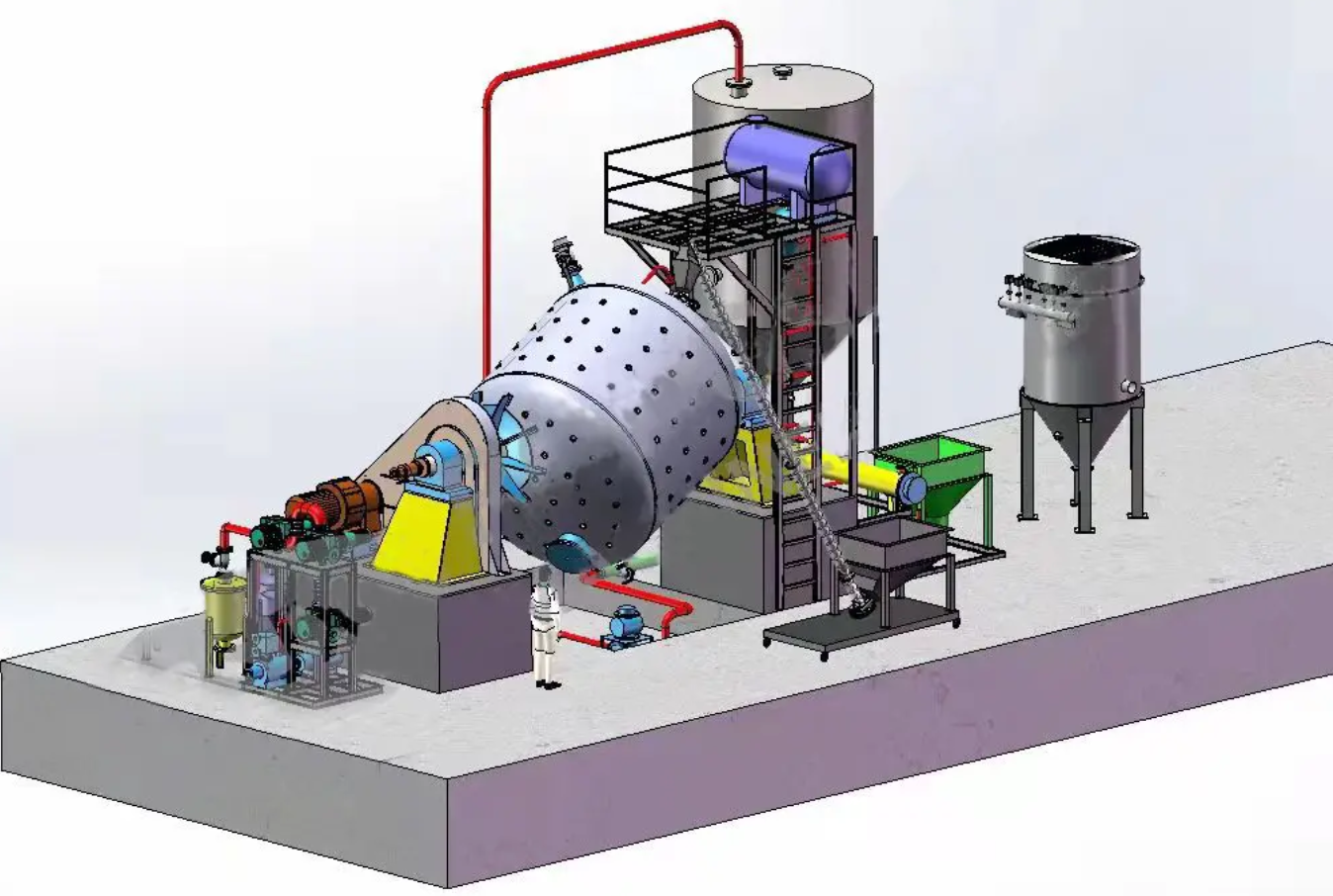

Key Components in High-Capacity Recycling Lines

A high-capacity PET recycling line, such as one rated for 6000kg/h, includes specialized machinery to handle large material volumes with minimal manual intervention. Equipment typically comprises de-balers, pre-shredders, trommel screens, label removers, hot washers, friction washers, sink-float separators, dryers, and optical sorters. These components are often arranged in multiple streams to ensure consistent feed despite supply variation. High-throughput lines demand heavy-duty construction, automated controls, and redundancy in critical units to avoid production stoppages. Backup systems for water filtration, residue removal, and heat management enhance uptime. Each element should be engineered to work harmoniously with upstream and downstream machinery. Flexibility in adjusting operating parameters is essential to accommodate feedstock quality variations across regions or seasons.

Customizing Lines for Local Conditions

Not every PET recycling line should be identical. Local infrastructure, energy costs, water availability, and labor rates significantly influence system design. In regions with high energy costs, choosing energy-efficient motors, heat recovery systems, and solar-assisted heating options can lead to substantial long-term savings. Areas with limited water access may benefit from closed-loop water treatment and reuse systems, which also support environmental compliance. If labor costs are high, automation and remote monitoring can reduce manual input and improve consistency. Dust control, noise reduction, and ergonomic safety features may be required depending on national regulations. Customizing the PET recycling line to suit these variables ensures operational sustainability and regulatory approval.

Energy and Water Management Strategies

Optimizing Water Use in Washing Stages

Water consumption is a major concern in any PET recycling line, especially when processing large volumes for bottle to fiber applications. Implementing water-efficient washing systems, such as counter-current rinsing and high-pressure low-flow nozzles, reduces overall consumption. Advanced water treatment setups using membrane filtration, dissolved air flotation, and pH balancing allow the water to be reused multiple times. Dirty water loops should be isolated from clean rinsing stages to prevent recontamination. Closed-loop systems not only conserve resources but also reduce wastewater treatment costs. Design strategies must include sedimentation tanks, oil separators, and easy-access filters for maintenance. With sustainability and cost control in mind, optimizing water usage directly enhances the feasibility of high-capacity PET recycling lines.

Reducing Energy Loads with Smart Drying Solutions

Drying is often the most energy-intensive phase in a PET recycling line. Conventional dryers can significantly increase operational costs if not optimized. Choosing IR or vacuum dryers for moisture reduction helps preserve PET integrity while reducing power consumption. Heat recovery units capture waste heat from one process and use it in another, significantly lowering net energy demand. Insulation, airflow optimization, and real-time monitoring of drying efficiency all contribute to energy savings. Integrating sensors that adjust drying intensity based on moisture levels prevents over-drying, which can damage flake properties. For 6000kg/h systems, energy-efficient drying is especially critical to keeping operating costs manageable and ensuring ROI.

Automation, Monitoring, and Maintenance

Centralized Control Systems and Sensors

Modern PET recycling lines are highly automated, with central PLCs managing each stage from bale opening to flake discharge. These systems offer dashboards for monitoring temperatures, water flow, motor loads, and contamination levels in real time. Alarms, data logging, and trend analysis support predictive maintenance and early fault detection. Automation reduces human error and improves throughput consistency. Integration with ERP systems allows seamless reporting and inventory tracking. Centralized control becomes more important as line capacity increases and manual oversight becomes impractical. High-capacity lines with integrated automation achieve better yield, uptime, and compliance with fewer personnel.

Preventive Maintenance and Spare Parts Strategy

Consistent performance of a PET recycling line depends on timely preventive maintenance. For fiber-grade flakes, even small delays or contamination can disrupt production. Maintenance schedules should be embedded into the control system, with reminders, spare parts inventory levels, and technician alerts. Selecting equipment from vendors with strong support networks and localized spare parts availability reduces downtime. Quick-swap components and modular construction help keep maintenance windows short. Lubrication, wear part inspection, and sensor calibration must be part of routine workflows. A dedicated maintenance plan aligned with shift schedules ensures maximum productivity, especially for high-capacity operations.

FAQ

What capacity PET recycling line is suitable for fiber production?

The choice depends on supply volume, market demand, and processing goals. For medium operations, a 1000–3000kg/h PET recycling line may be sufficient, while large industrial facilities targeting high-volume fiber production often require a 6000kg/h capacity system. Larger lines benefit from economies of scale and automation but need proper feedstock and infrastructure support.

Why is intrinsic viscosity important in the bottle to fiber process?

Intrinsic viscosity (IV) reflects the polymer chain length and affects the melt flow behavior of PET during fiber spinning. Maintaining a consistent IV ensures uniform fiber properties such as strength, elasticity, and dye uptake. Recycling lines must minimize IV degradation during washing and drying to meet fiber production standards.

Can a PET recycling line be customized for different regional conditions?

Yes, customization is critical for optimal performance. Factors like water availability, electricity cost, labor rates, and regulatory requirements influence equipment selection and layout. Modular and configurable PET recycling lines allow adaptation to various local conditions without compromising output quality.

What features help reduce operational costs in a PET recycling line?

Key cost-saving features include energy-efficient motors, water recycling systems, heat recovery units, automation, and centralized control. Proper throughput design and preventive maintenance plans also minimize unplanned downtime and labor costs. These elements combined make high-capacity lines more economical and sustainable in the long run.