RECYCLING POST CONSUMER

A new era. With POLYTEC.

Odour optimised, energy efficient, recyclable. And for specific applications: super clean and food contact compliant.

Post consumer recycled pellets of the future can do more. Get more out of your material stream with innovative POLYTEC technologies featuring digital assistance systems. More quality, more productivity. For a better end product. Take the new energy saving dual filtration solution (automatic belt melt filter+back flusher filter) , for example, as well as ReFresher anti odour technology . Enter this future right now With POLYTEC. into the new era of post consumer recycling.

Heavy contamination and mixed, damp material, and different collection systems often make recycling post consumer plastics a complex challenge. To obtain high-quality secondary raw materials from thin-walled LDPE films or thick-walled PE or PP regrind requires particularly reliable stable processes and plant that is robustly constructed. Maximum performance with high-quality processing is what is needed, as offered by the recycling systems from POLYTEC that are designed for post consumer waste.

No matter what challenge you face implementing your post consumer project, with our unrivalled range of technological solutions in the most diverse fields of application and extensive experience gained from than 10 years of recycling machine construction, we are at your side.

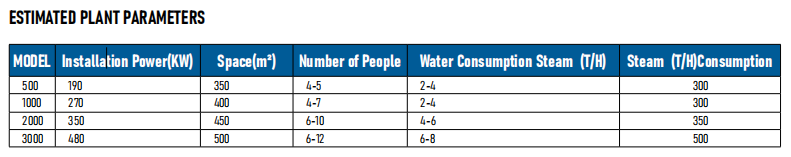

1. Ideal material preparation in the Preconditioning Unit

Cutting, homogenising, heating, drying, compacting, buffering and dosing – in a single stage. The dynamically controlled Preconditioning Unit (PCU) is multitalented. It prepares the plastic ideally for the extruder and sets the course for consistently high end product quality already at the beginning of the recycling process.

2. Gentle melting, low shear

Because it has been preheated in the PCU, the material in the extruder reaches the required melt temperature more quickly. This shortens the extrusion process (shorter extruder), the time taken to melt the material, and the time it spends in the extruder.

3. Highly efficient filtration

Thanks to the low shear stress, impurities are hardly broken up and are therefore large enough to be removed easily and efficiently by the POLYTEC belt melt filter before the melt is homogenised.

Against odour and discolouration:

The early removal of impurities such as cellulose (wood, paper), rubber and silicone means that they can no longer outgas or overheat later and no unpleasant odours or discolourations develop, which is a decisive quality bonus for the melt.

4. Perfect homogenisation

Greater homogenisation efficiency downstream of filtration and upstream of degassing enhances the subsequent degassing performance and improves the characteristics of the melt

5. Powerful degassing

Highly efficient triple degassing(in real full-vacuum state):

The first stage of degassing takes place at the start of the process in the PCU. Step two is second extruder degassing, which is made possible by the optimised screw design.

……after melt filtration(in real full-vacuum state)

The final triple venting degassing at the extruder is particularly effective and removes gas inclusions which are still present from the melt.

REFRESHER

High-efficiency anti-odour technology.

Thermal-physical cleaning process without additives

The ReFresher cleaning process reduces odours caused by low-volatile, high-molecular substances. The technology keeps the pellets at the temperature required for fast and deep-cleansing discharge of volatile materials.

Especially energy-saving: The ReFresher uses the system's intrinsic energy from the pellets, which are preheated during the extrusion process (at least 60 °C required).

LOW VOLATILE ODOURS OUT

Continuous odour discharge with constant heated purge gas

No complex vacuum system required

First in, first out: same treatment for all pellets

OUTPUT STAGE 1

QUALITY PELLETS

Perfectly filtered, homogenised and degassed - ideal for a variety of high-quality applications.

Get even more by using the QualityOn continuous quality monitoring system:

only precisely specified pellets enter the ReFresher.

OUTPUT STAGE 2

ODOUR OPTIMISED

For even higher quality applications, e.g. in the automotive, living space and design sectors.

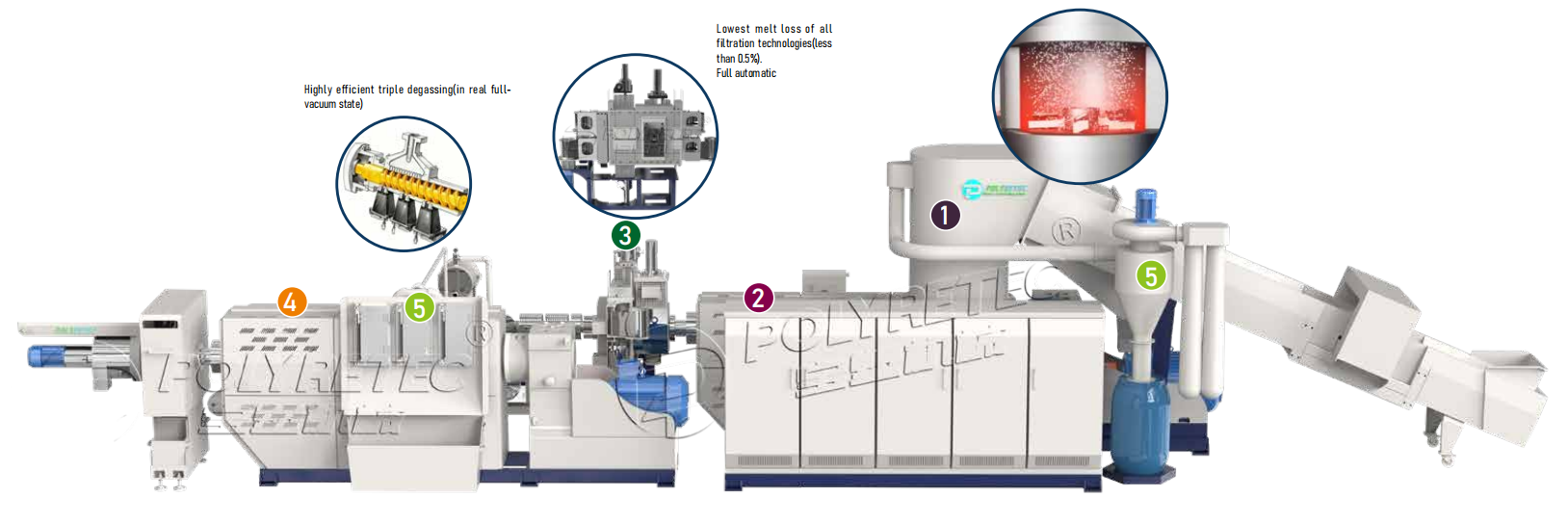

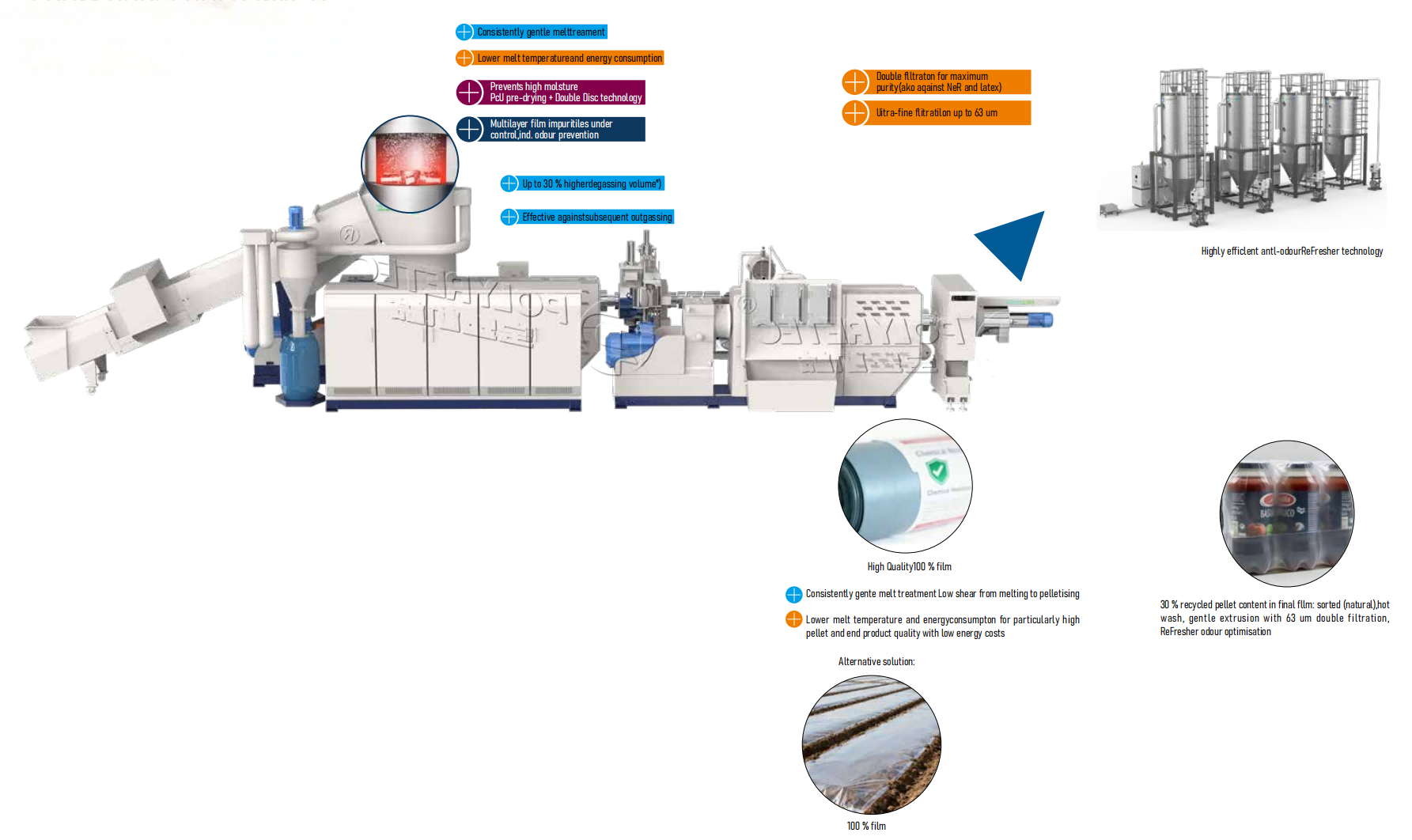

APPLICATION LD/LLDPE

STRETCH AND SHRINK FILMS

Large (baled) film sections

such as bulk packaging and supermarket films with paper labels

High market potential, commercially attractive. long-term growth in the market, high-quality input material, relatively pure feed (predominantly LD/LDPE films), thanks to high and consistent.

POLYTEC quality, high recycling rates of recycled pellets in new film products are possible (with the same mechanical performance). Depending on the current rPE market price, high cost savings in film production are possible by incorporating recycled material (compared to using all virgin material)

THE SOLUTION

LD/LLDPE STRETCH AND SHRINK FILMS

High-performance filter prevents burnt odours and discolouration:

Temperature-sensitive cellulose contaminants (paper labels, wood particles) are removed at an early stage. Additional bonus: because the operating temperature is lower in the compact Zone, it significantly reduces the melt temperature, and every degree less counts!

Up to 30% higher degassing volume*

Thanks to the design of the Compact, it delivers extremely powerful degassing performance that effectively prevents the re-gassing of already degassed melt

Improved, temperature-reduced pressure build-up

Compact Zone with mild, short transport screw instead of discharge metering zone combined with special melt pump

Double filtration for maximum purity

Final ultra-fine filtration for particularly high pellet purity

Lower melt temperature and energy consumption for particularly high pellet and end product quality with low energy costs

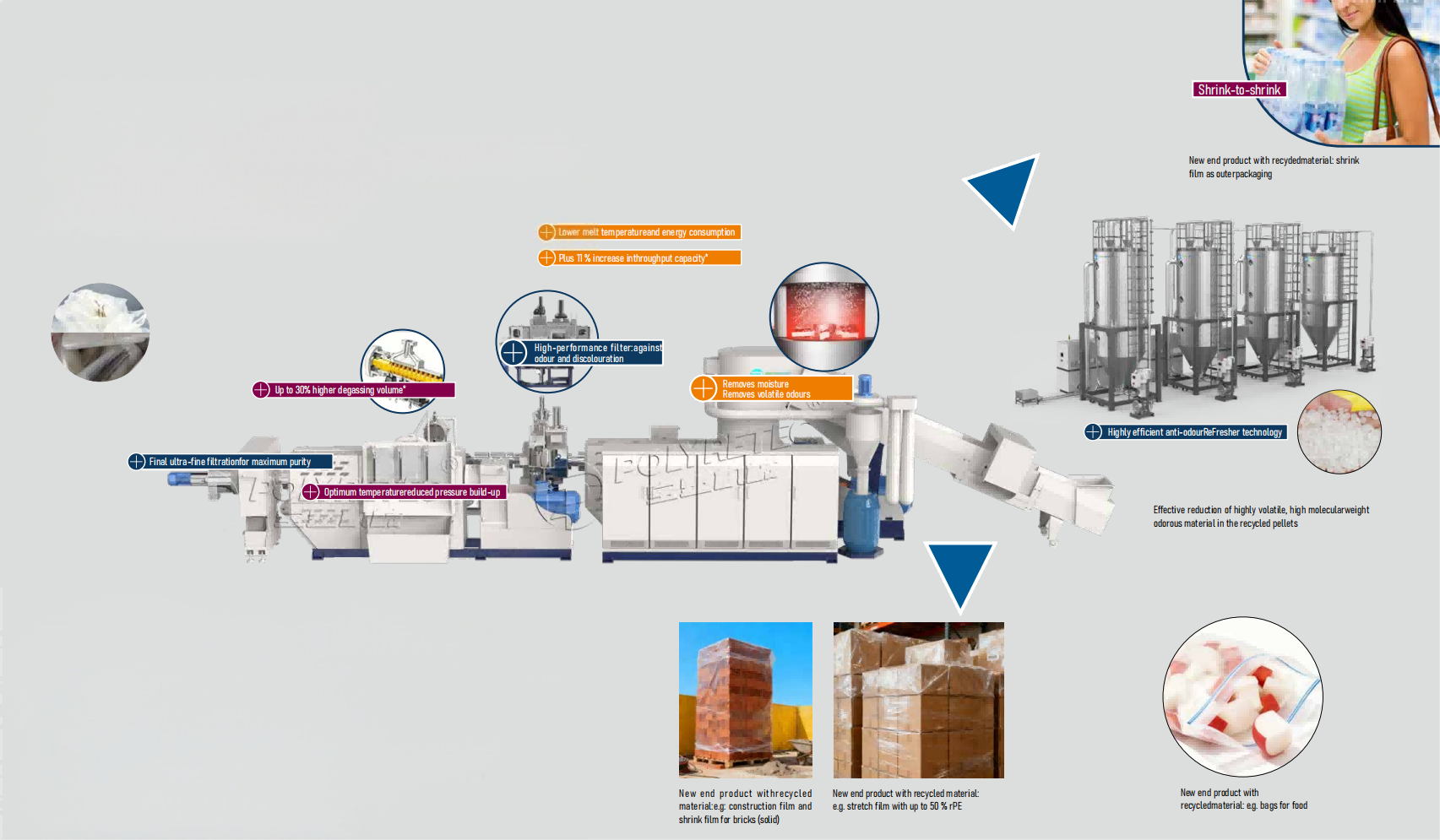

APPLICATION

Agricultural film

Wrapping films, silage films, agricultural stretch films, cover films, greenhouse films

Great commercial potential:

market with long-term growth, high-quality input material relatively consistent (mainly LDPE films),

low foreign polymer contamination

High and varying moisture(outdoor storage, wash system)

Very high level of contamination: due to abrasive, mineral material(e. g. sand, stones), organic impurities(e.g. soil, grass, vegetable scraps, roots, wood particles) and metals

and at the same time very soft and mostly only round 25 μm to 100 μm thin films(mainly LD/LLDPE films)

THE SOLUTION

Agricultural film

High-performance filter against heavy contamination Prevents odour and discolouration

Improved temperature reduced pressure build-up

Double filtration for maximum purity

Particularly strong degassing

High-performance filter against heavy contamination

Particularly strong degassing

Removes volatile odours

Gentle melting

Consistently gentle melt treatment

Lower melt temperature and energy consumption

Great commercial potential:

market with long-term growth, high-quality input material relatively consistent (mainly LDPE films),

low foreign polymer contamination

High and varying moisture(outdoor storage, wash system)

Very high level of contamination: due to abrasive, mineral material(e. g. sand, stones), organic impurities(e.g. soil, grass, vegetable scraps, roots, wood particles) and metals

and at the same time very soft and mostly only round 25 μm to 100 μm thin films(mainly LD/LLDPE films)

Up to 30 % higher degassing volume* Thanks to the design of the compact, it delivers extremely powerful degassing performance that effectively prevents the re-gassing of already degassed melt

Improved, temperature-reduced pressure build-up Compact Zone with mild, short transport screw instead of discharge metering zone combined with special melt pump

Double filtration for maximum purity Final ultra-fine filtration particularly effective against any remaining abrasive impurities for thinner end products and to protect against wear on the downstream (film) production machine

Consistently gentle melt treatment Low shear from melting to pelletising

Lower melt temperature and energy consumption for particularly high pellet and end product quality with low energy costs

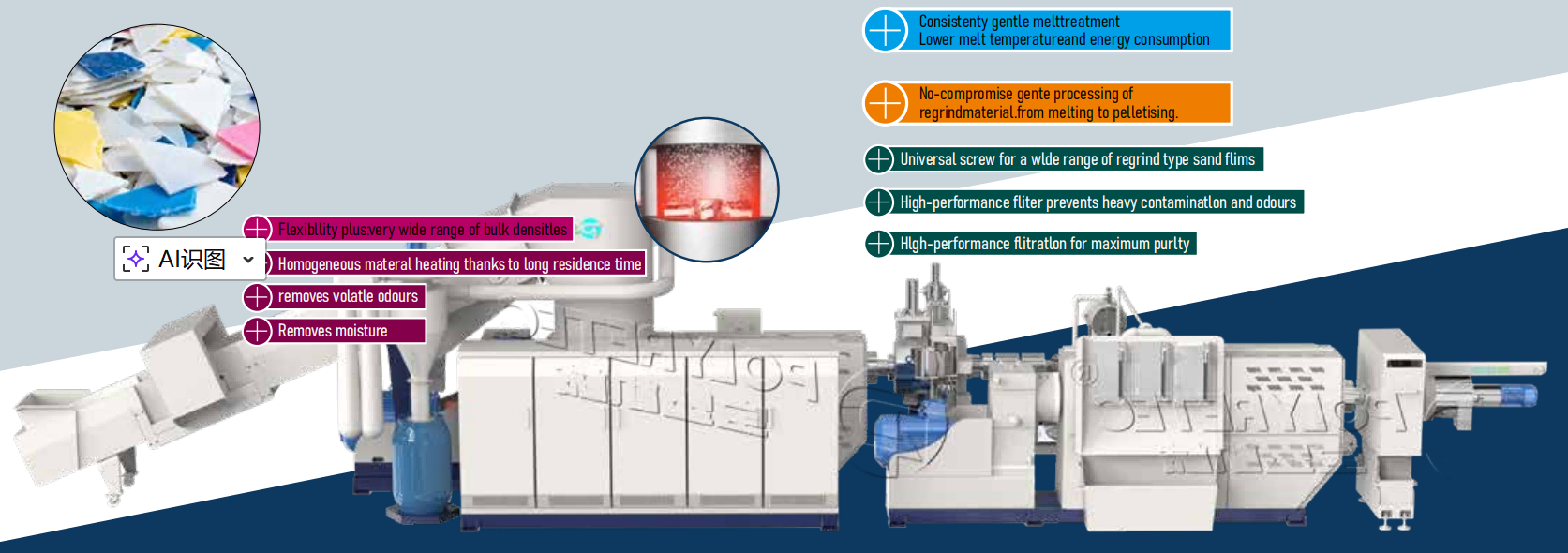

APPLICATION

HDPE AND PP REGRIND MATERIAL FROM HOUSEHOLD PACKAGING

High moisture up to 4 %

Strong, varying degrees of contamination with various impurities, e.g. rubber and silicone(from closure caps), paper and foreign polymers(PET, PA) e.g. from labels, wood

Unpleasant odours in the input material in the form of substances migrated from foodstuffs, cosmetics and cleaning agents, as well as from contaminants adhering to the surface

Prevents additional odours in the molten state(during the recycling process) due to potential odour triggers such as rubber, silicone, paper and wood

A wide range of regrind bulk densities (from thin-walled flakes to thick-walled regrind) and different polymers (PE, PP, PS, ABS, etc.) can be processed with just one system

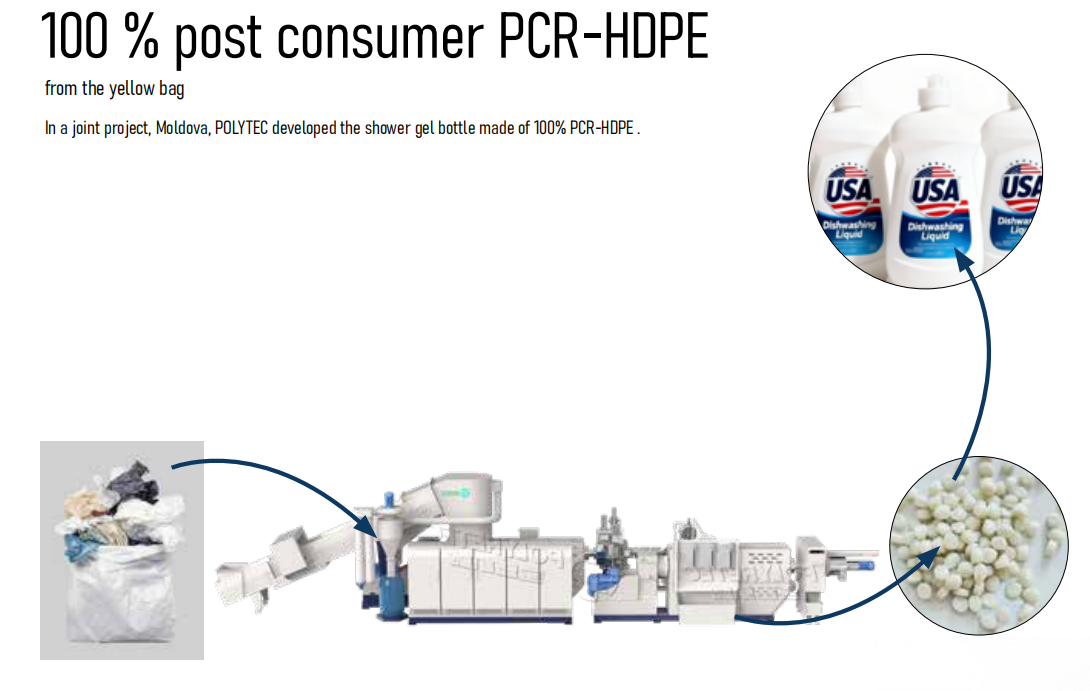

BEST PRACTICE

HDPE and PP regrind material

COSMETIC GRADE Quality on rinse off.

Thanks to state-of-the-art POLYTEC technologies, many years of experience and working together closely with our partners along the value chain, high-end cosmetic applications ,such as packaging for rinse-off products, can be made directly from post consumer recyclate. Rinse off products are body care products that are used to cleanse the skin and hair, but are rinsed off with water and therefore do not remain on the skin or hair.

What is decisive for the high decontamination performance of this POLYTEC technology combination is the pre-treatment of the material during the one-hour residence time in the Preconditioning Unit of the recycling extruder and the additional removal of volatile odorous substances from the pellets using ReFresher anti-odour technology

THE SOLUTION

HDPE AND PP REGRIND MATERIAL

Homogeneous heating thick-walled flakes made from regrind material

Long residence time (up to 1 hour)thanks to the rotation of the specially designed rotor disc with simultaneously higher filling level

Additional bonus: additives such as CaCO3 are distributed homogeneously thanks to the longer residence time and high filling level.

Additional flexibility: very wide range of input bulk density from 30 to 800 g/l

Perfect for thin-walled rigid flakes and thick-walled regrind material as well as for other forms of material such as films and non-woven applications.

The advantage of being able to process material regardless of its bulk density is that, compared to conventional twin screw solutions, this complies with the trend towards ever thinner packaging films.

No-compromise gentle processing of regrind material - from melting to pelletising. For a particularly high-quality recycled pellets and end products with the best specifications in terms of mechanical properties, surface quality, dyeability, odour etc, and with a particularly high recyclate content.

High-performance filter prevents heavy soiling and odours

Early and effective removal of rubber, silicone, paper, wood, etc. counteracts subsequent burnt odours

High-performance filtration for maximum purity Considerably higher filtration efficiency compared to conventional single screw and twin screw systems

Additional advantage of a universal auger.

Fast changeover without changing the screw - from thin-walled HDPE or PP flakes to thick-walled WEEE regrind particles and even film in no time at all

APPLICATION WASHED

LD/LLDPE FILM FLAKES FROM HOUSEHOLD WASTE COLLECTION

High and varying moisture: Up to 12 % mainly due to upstream washing process

Heavy, varying contamination High proportion of paper, aluminium and foreign polymers (PET, PA) originating from multilayer films

Organic contamination mainly from food residues and lactic acid Other foreign polymers such as nitrile rubber (NBR) from disposable gloves

THE SOLUTION WASHED LD/LLDPE FILM FLAKES FROM HOUSEHOLD WASTE COLLECTION

Handles high moisture: thanks to efficient pre-drying in the Preconditioning Unit (PCU) and Double Disc technology, materials can be processed with a residual moisture of up to 12 %.

Powerful filter against impurities from multilayer films, prevents burnt odours, the POLYTEC belt melt filter efficiently removes contamination from multilayer films such as aluminium and foreign polymers (PET, PA). Effective against burnt odours: temperature-sensitive paper fragments are eliminated at an early stage.

Final ultra-fine filtration for maximum purity* Ultra-fine filtration down to 63 μm possible - thanks to temperature-reduced Compact mode of operation, also ideal for handling application-typical NBR or latex particles from disposable gloves

Effective against organic contamination (mainly from food residues, and lactic acid)

Initial pre-degassing takes place in the Preconditioning Unit (additional bonus: also protects the extruder screw)

High-performance filtration Up to 30 % higher degassing volume*: Extremely high degassing performance thanks to Compact design

*Prevents subsequent outgassing: because it is isolated from the build up of pressure and temperature, unlike in other dual filtration solutions, in the compact the highest temperature is not at the end of the extruder, but already upstream of the degassing stage. This counteracts subsequent outgassing of the melt.

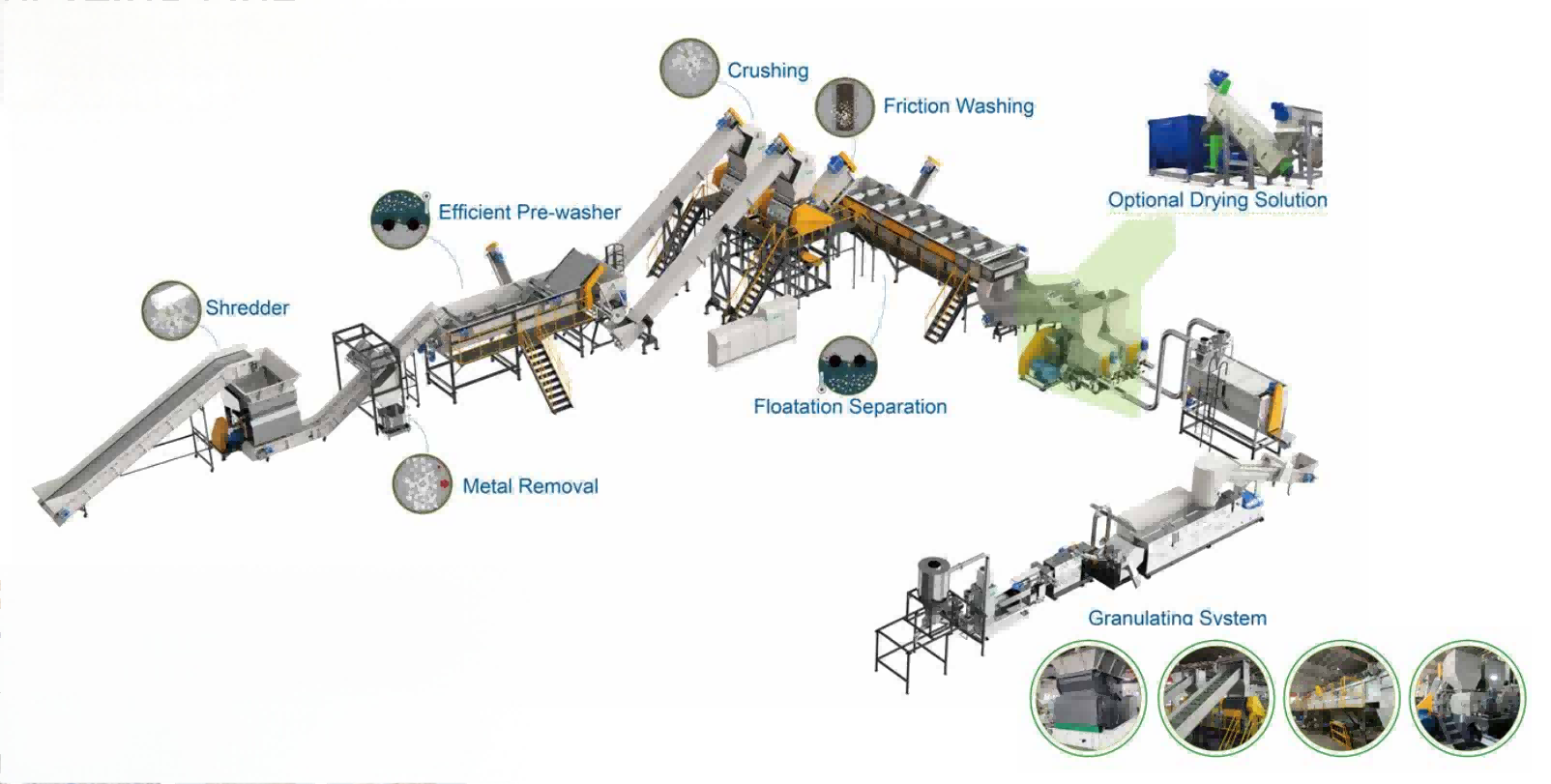

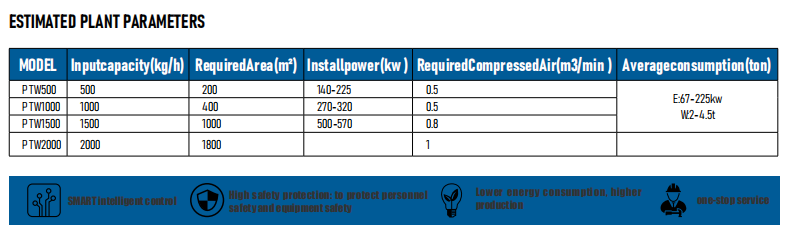

HIGH VALUE PP PE SOFT PLASTIC WASHING RECYCLING AND GRANULATING LINE

OUTPUT 500-2000KG/HR

Suitable for different kinds of soft plastic materials (Packing film, PP jumbo bag, PP woven bag, PP fishnet). are able to separate high density and dirty materials

Plastic will get high speed friction around 720rpm and sticky material and heavy sediments will be rubbed off efficiently.

Final Moisture can be around 3%~5% in the end. totally suitable for pelletizing Line of our own brand.

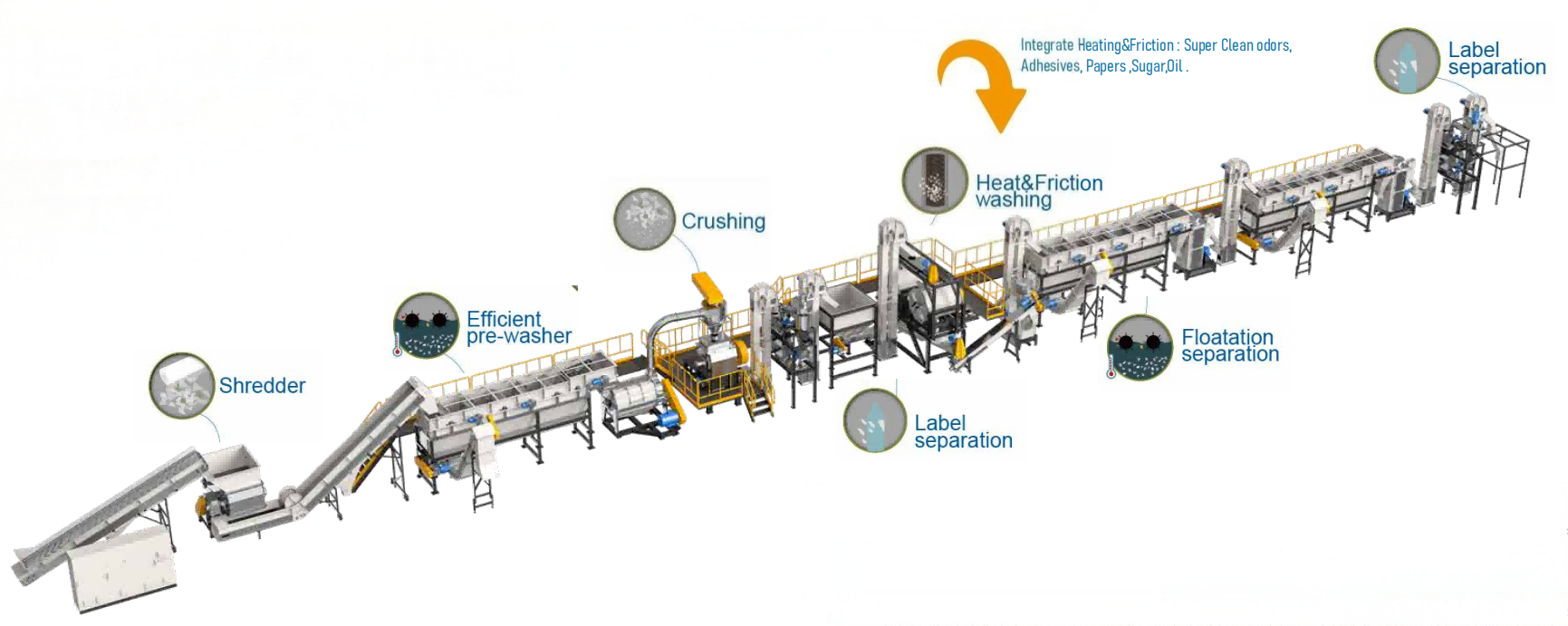

HIGH GRADE RIGID PLASTIC WASHING RECYCLING

LINE (PE/PP/HDPE/PO/)

Output 500-5000kg/hr

1.Suitable for different kind of rigid plastic materials (HDPE bottle, containers, PP injection product, home-consumer plastic)

As machine installed sorting system, heating&friction washer, water treatment plant, VOC dehumidification system, this kind of line meets the standard of FDA which is available to contact food packaging.

Less than 0.5-2% moisture, the material is suitable for high quality pelletizing.

2.Description of crushing washing process module:

Rinsing washer: the bottle contains the metal spring and other harmful substances through the first shredding all have been separated from the bottle, after the friction scattered into the first rinsing washer, remove the majority of metal spring and aluminum foil and other submerged HDPE PP bottle and proportion of greater than 1 PE / PP bottle Hot washing module: after crushing and friction, most of the labels and bottles have been separated, only the aluminum foil containing adhesive and hot melt has no separation, through the first stage of separation into hot washing high temperature heating&friction, and remove the stubborn dirt, adhesive and aluminum foil to restore the original color; high temperature heating module control temperature is greater than 90℃ and heating for more than 30 minutes, design two heating&friction tanks to ensure the temperature and time of the specimen production line to ensure the cleaning quality;