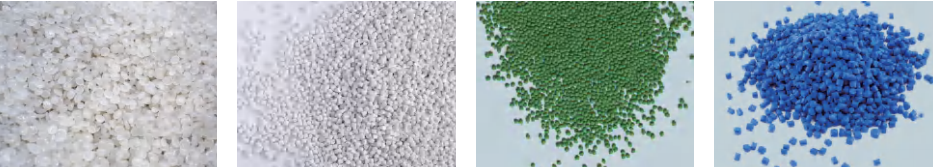

| Model | Screw diameter | Output (kg/h) | Power consumption | Labor | L/D | Rotating speed |

| (mm) | (KW) | (person) | (rpm) | |||

| PTC90-100 | 90 | 110-180 | 110 | 1月2日 | 18-42 | 10-150 |

| PTC100-120 | 100 | 200-350 | 150 | 1月2日 | ||

| PTC130-150 | 130 | 450-600 | 260 | 2月3日 | ||

| PTC150-160 | 150 | 600-700 | 320 | 2月3日 | ||

| PTC185-200 | 185 | 800-1200 | 380 | 2月4日 |

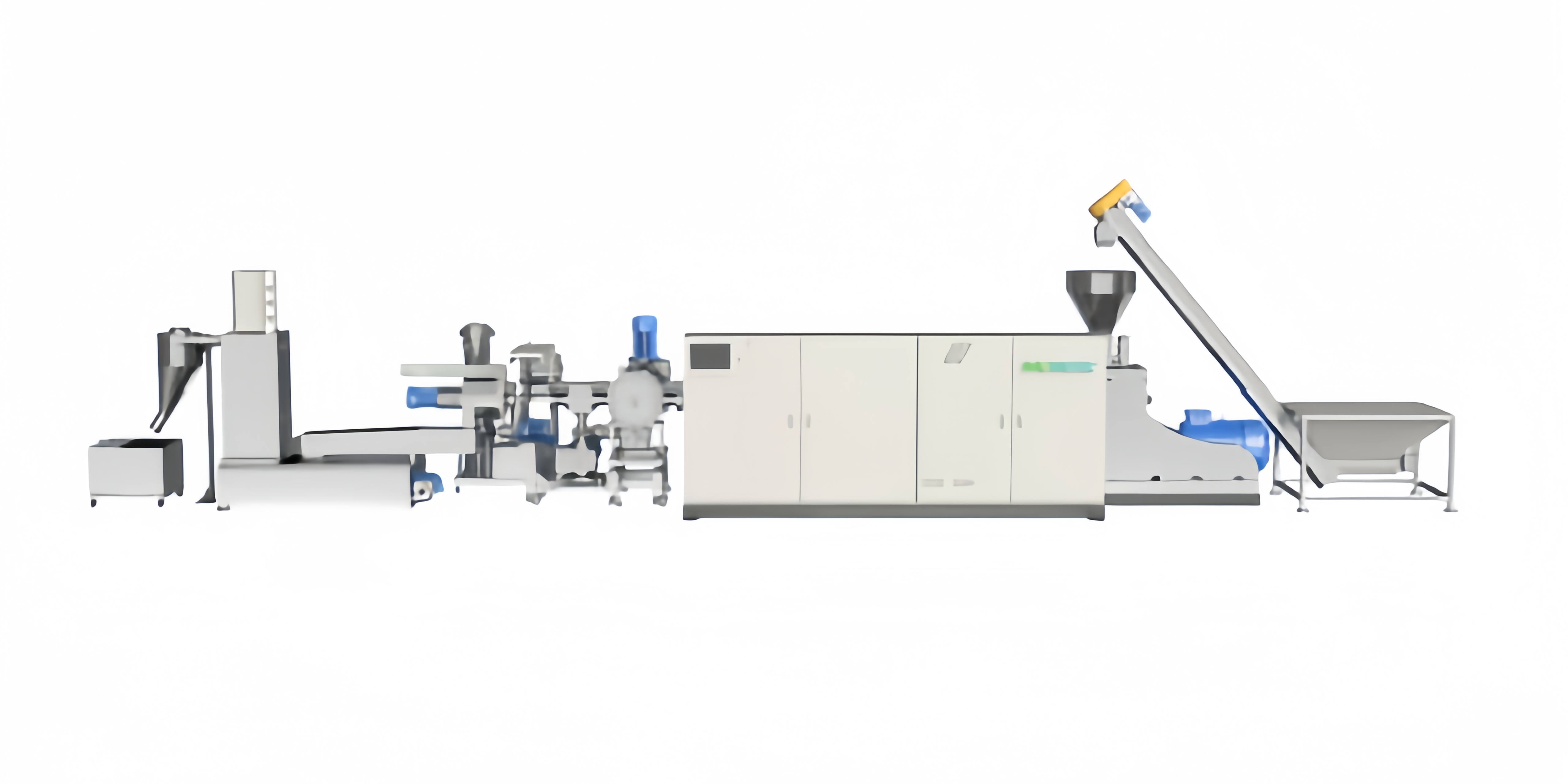

| Machine | Photo of machine | Technical specifications |

| Single screw extruder |  |

High efficiency barrel and screw used for extruder with excellent plasticizing result and high output capacity. Adopt high wear resistant alloy material to ensure 1.5 times service life of normal one. Vacuum pumping hardware |

| Plate type, piston type, and automatic self-cleaning type filter, you have different choice according to impurity contents in material and your habit. |  |

Comparative advantages of large area net changer and plate type net changer: 1) larger filtration area 2-4 times, particle quality greatly improved 2) lower energy consumption :40-70 per cent lower energy consumption 3) the true meaning of no stop network without pressure fluctuations, water ring particles thickness more uniform. 4) higher durability and tightness 5) reduce filter mesh cost by 20% effectively 6) effectively prolong the time of network exchange, save manpower, reduce waste of raw materials |

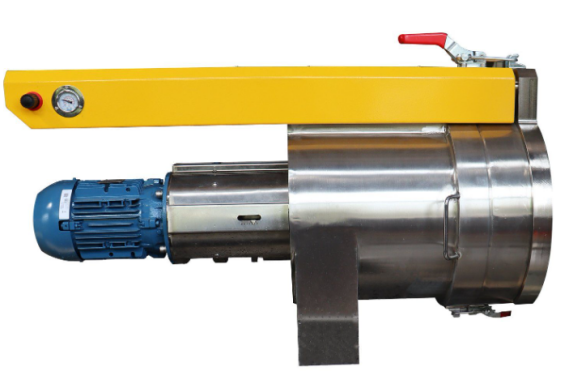

| Pelletizing |  |

New European design water ring pelletizer, Cutting speed of pelletizer controlled automatically by PLC according to the pressure of die head, which could achieve the uniform size for output pellets. |

| Drying system |  |

Centrifugal dryer match with hot air drying system |

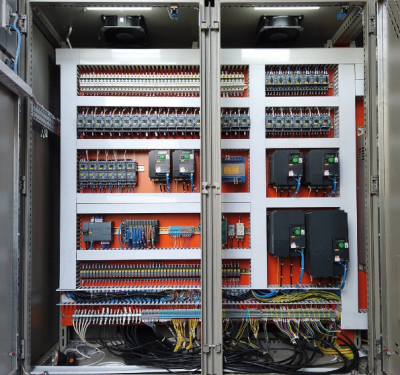

| Smart Control cabinet |   |

SMART intelligent control:

|