Raw materials: all kinds of TV shell, computer shell, refrigerator shell, etc

| Model | Capacity | Installation power | Space | Compressed air | Water |

| (kg/h) | (kw) | (m2) | (m3/min) | (m3) | |

| ABS500 | 500 | 98 | 500 | 0.5 | 2 |

| ABS1000 | 1000 | 150 | 700 | 0.5 | 2 |

| ABS2000 | 2000 | 230 | 1000 | 0.5 | 3 |

| ABS3000 | 3000 | 420 | 1500 | 0.5 | 4-6 |

| Machine name | Introduction | |

| Manual sorting belt conveyor |

Function: manually sort out PVC bottle, labels, and other impurities.

|

|

| Double shaft shredder |

break the material to 40-50mm

|

|

| Belt conveyor and metal separator | ||

| Rinsing wash tank |

For PP PE bottle rinsing, metal, stone and other submerged impurities from the material

|

|

| PTC Wet Crusher |

Fine grinding

|

|

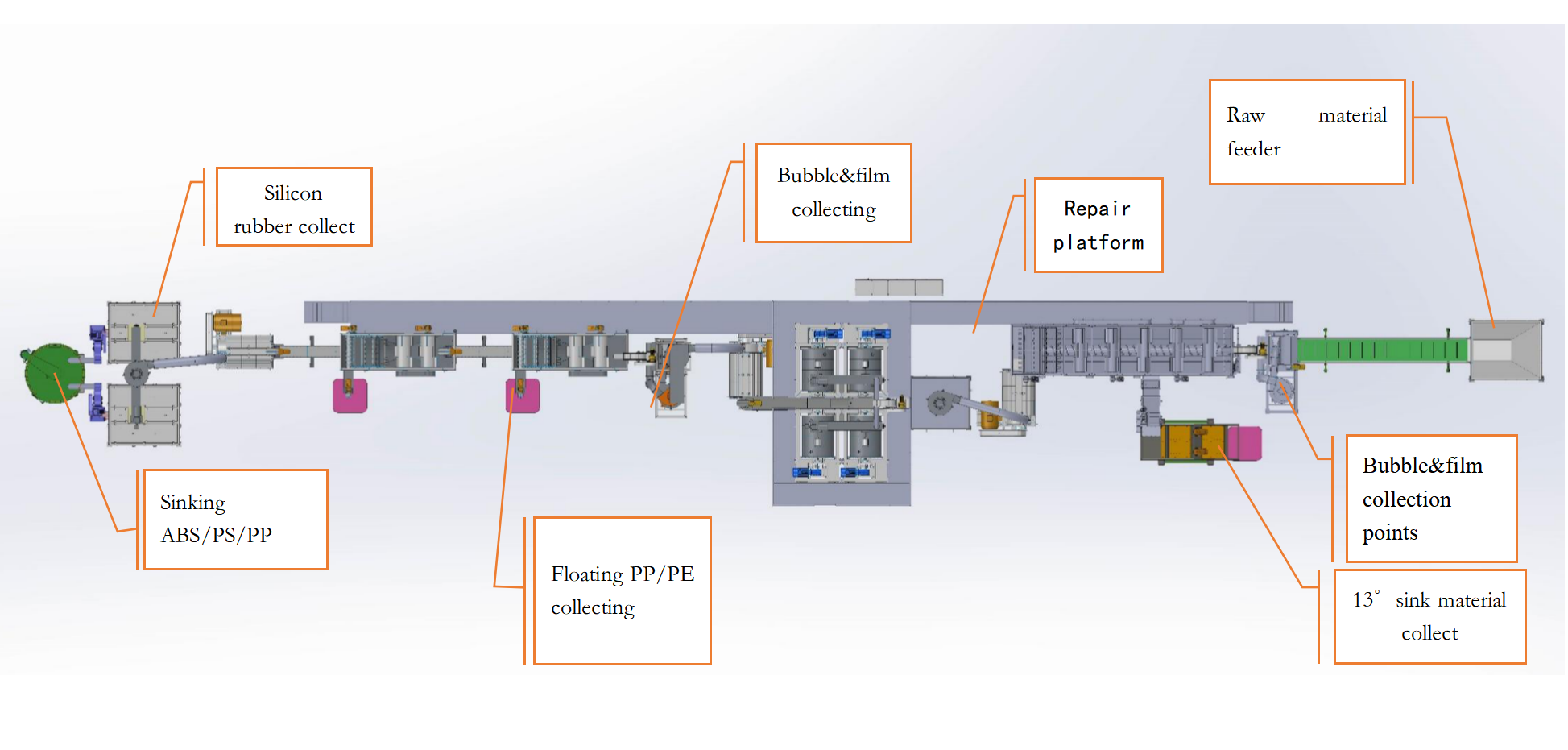

| Floating washing tank |

Cleaning flakes and separating remained dirt and dust

|

|

| Centrifugal dryer |

Remove dirty water

|

|

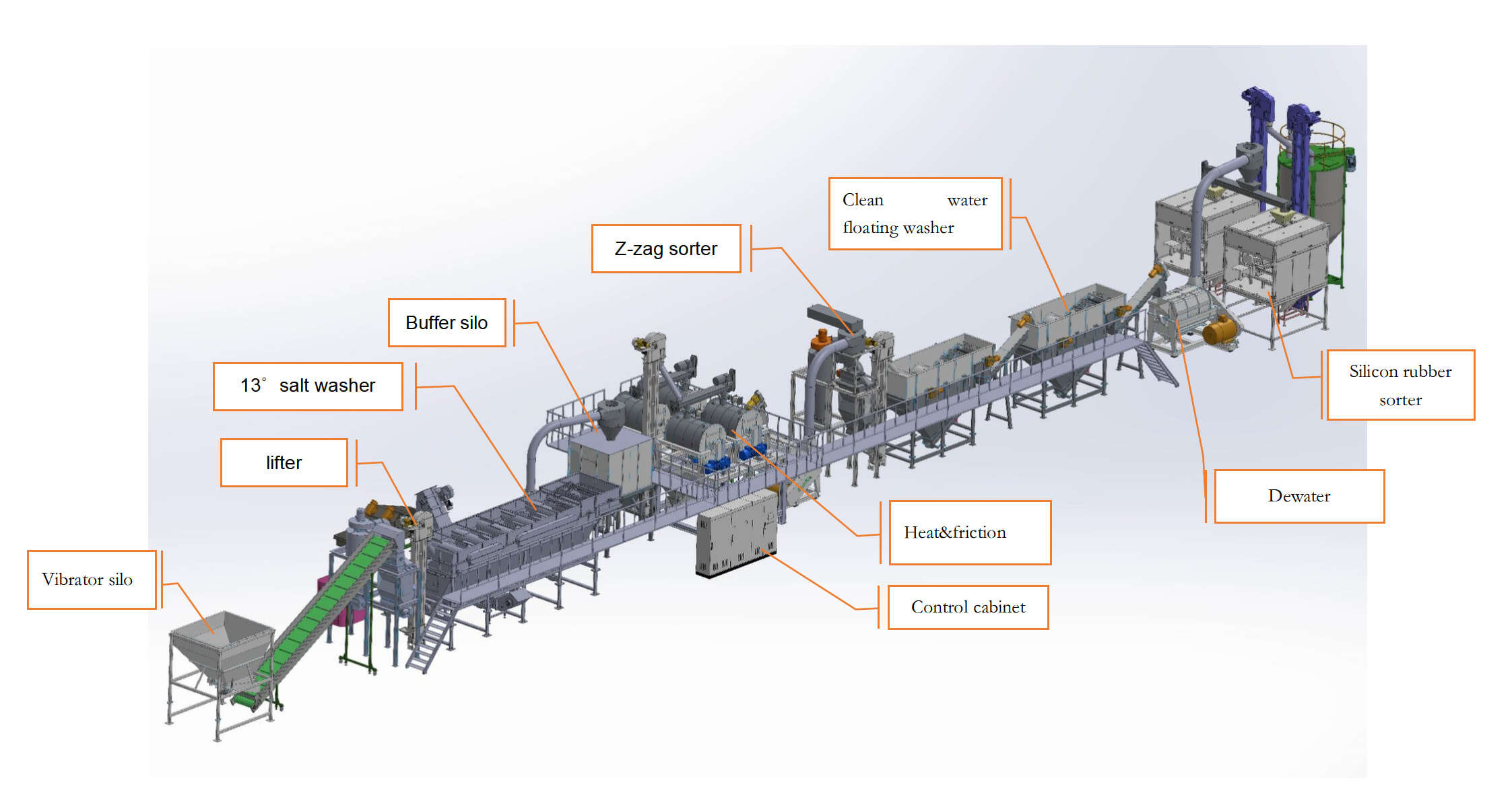

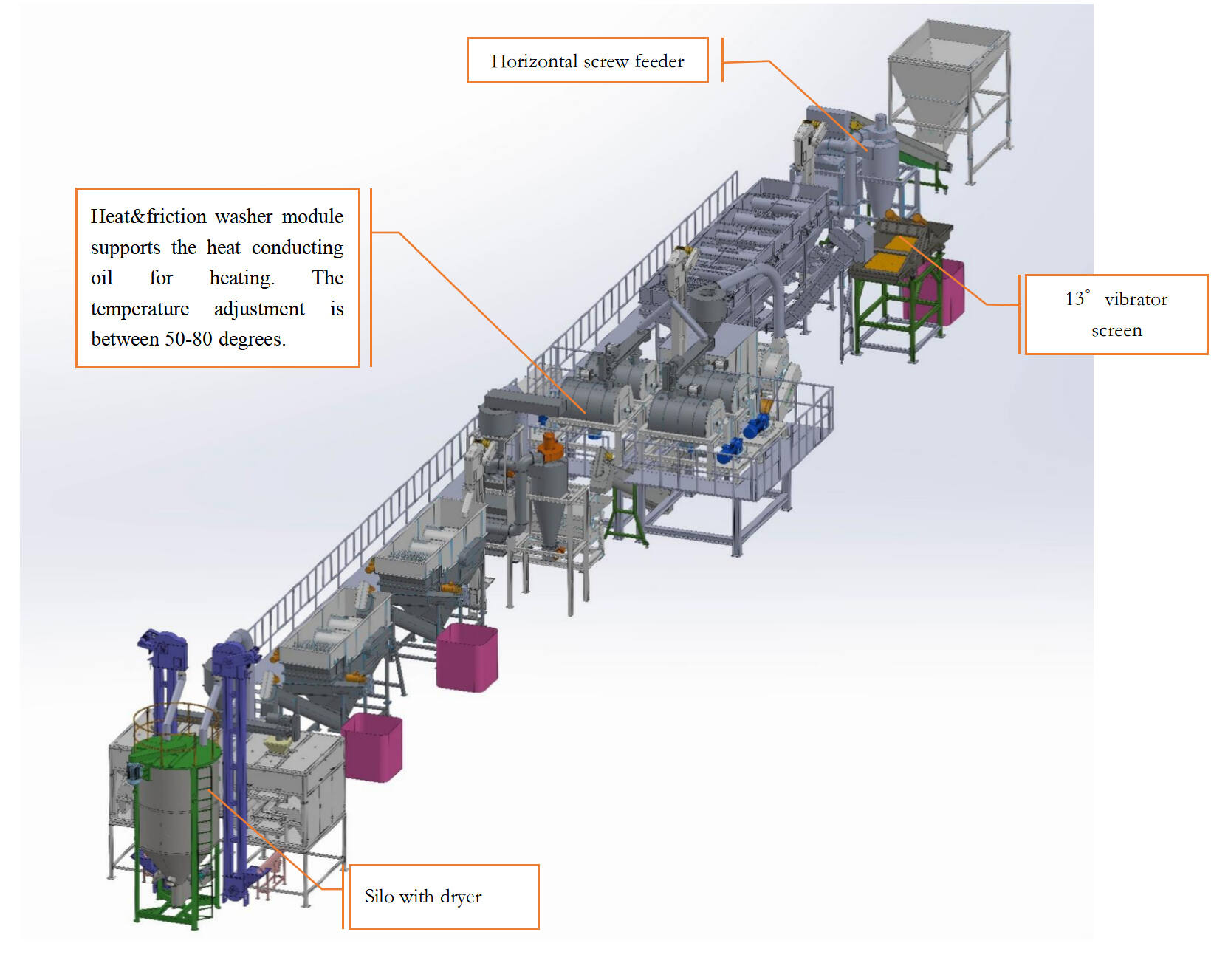

| Hot&friction washer | Rubbing clean the material and remove the foam and paint on the material surface by heating, Used to add detergent and heat the flakes when high-speed friction cleaning, removing dirt. |

|

| Zig-zag Air sorter |

Separate label dust from materials

|

|

| Floating washing tank |

Cleaning flakes and separating remained dirt and dust further. |

|

| Centrifugal dryer |

Drying

|

|

| Hot air dryer |

Drying

|

|

| DCS intelligent recycling line control system Upper computer control system: Features: ①The production process is controlled in real time, and data . ② Monitor the operating status of the equipment in real time ③The system is equipped with an intelligent medical examination module to remind the equipment of regular inspection items in real time to avoid false or missed inspections. |

|

|

|

Silica gel separator

|

Separate silica gel | |

|

Electrostatic separator

|

Separate PP PE ABS PS | |

Brand of Components:

| All type of bearings use Japanese NSK or German SKF, |  |

| The motor is SIEMENS or WEG |  |

| The reducer adopts Ruidesen |  |

| Inverter |  |

| Low voltage components |  |

| PLC Module |  |

| Imported conductivity sensor is used for hot washing detection | |

| DCS SYTEM | SCIYON WISDOM |