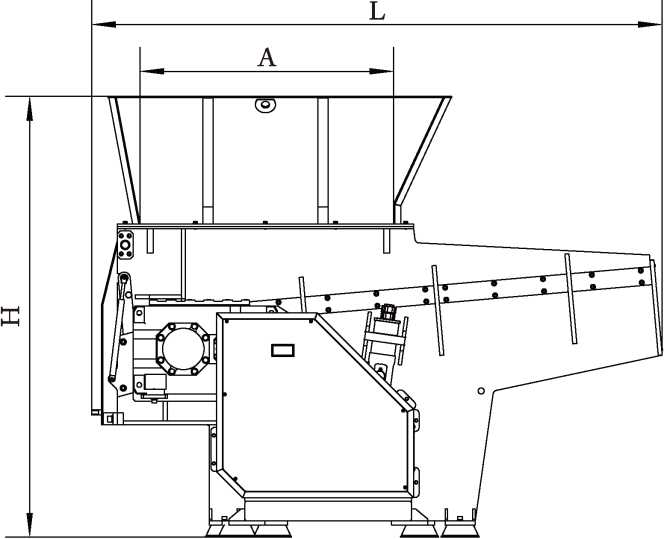

| Item \Model | P260 | P380 | P3120 | P3150 |

| AxB Crushing chamber(mm) | 500x580 | 850x800 | 850x1200 | 850x1400 |

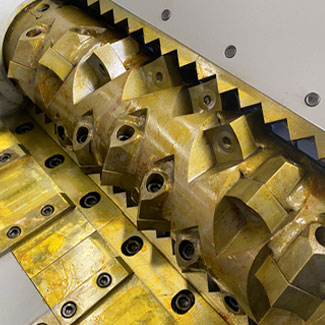

| Rotor diameter (mm) | 230 | 390 | 390 | 390 |

| Rotor speed (RPM) | 75 | 75 | 85 | 85 |

| Pusher stroke (mm) | 500 | 850 | 850 | 850 |

| Rotor knife qty (pcs) | 26 | 38 | 58 | 82 |

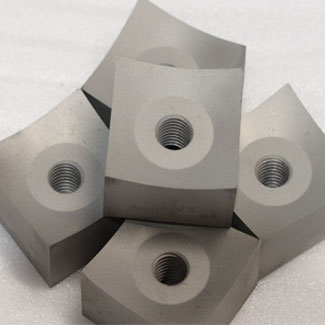

| Counter knife qty (pcs) | 2+2 | 2+2 | 3+3 | 3+3 |

| Screen opening (mm) | 40 | 40 | 40 | 40 |

| Motor power (kW) | 18.5 | 37 | 55 | 75 |

| Hydraulic station power (kW) | 1.5 | 3.7 | 5.5 | 5.5 |

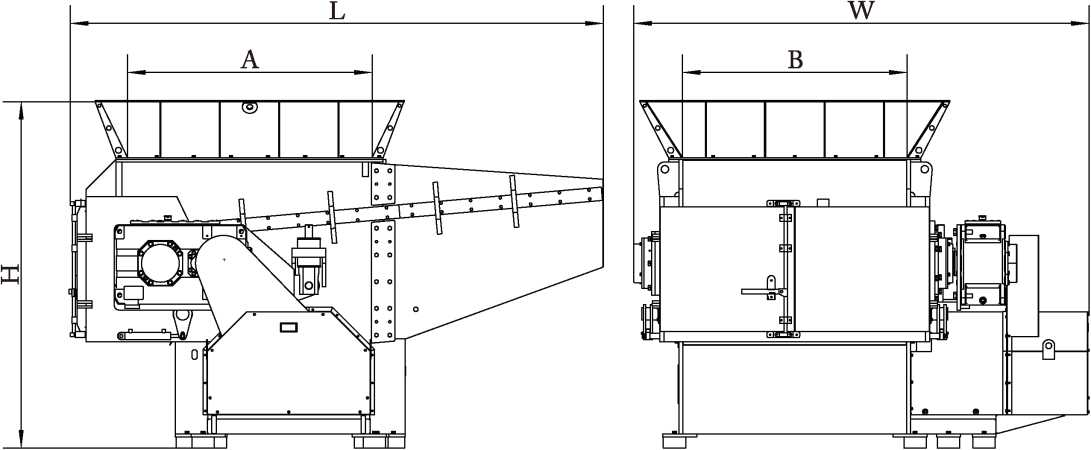

| LxWxH Dimension (mm) | 1760x1300x | 2850x1760x | 2850x2560x | 2850x2760x |

| 1850 | 2210 | 2330 | 2330 | |

| Weight (kg) | 1750 | 4150 | 5300 | 5900 |

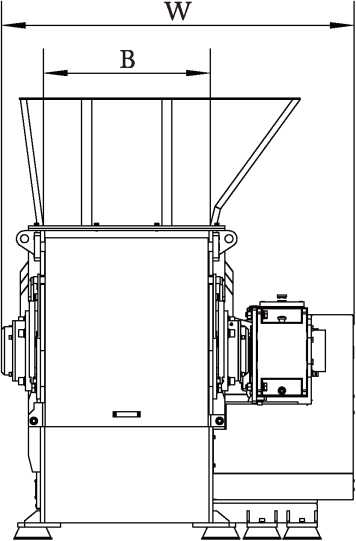

| Item \Model | T4150 | T4200 | T6170 | T6220 | T7180 | T7240 |

| AxB (mm) Crushing chamber | 1200x1470 | 1200x1970 | 1200x1600 | 1200x2170 | 1200x1770 | 1200x2370 |

| Rotor diameter (mm) | 460 | 460 | 600 | 600 | 700 | 700 |

| Rotor speed (RPM) | 85 | 85 | 85 | 85 | 85 | 85 |

| Pusher stroke (mm) | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 |

| Rotor knife qty (pcs) | 88 | 118 | 94 | 130 | 106 | 142 |

| Counter knife qty (pcs) | 3+3 | 4+4 | 3+3 | 4+4 | 4+4 | 4+4 |

| Motor power (kW) | 90 | 55+55 | 132 | 90+90 | 90+90 | 132+132 |

| (kW) Hydraulic station power | 5.5 | 7.5 | 7.5 | 11 | 11 | 11 |

| Screen opening (mm) | 40 | 40 | 40 | 40 | 40 | 40 |

| LxWxH Dimension (mm) | 3710x2880x | 3710x4150x | 3920x2750x | 3920x4500x | 4070x4070x | 4070x4670x |

| 2530 | 2530 | 2720 | 2720 | 2870 | 2870 | |

| Weight (kg) | 11000 | 14800 | 13800 | 18000 | 16000 | 20000 |