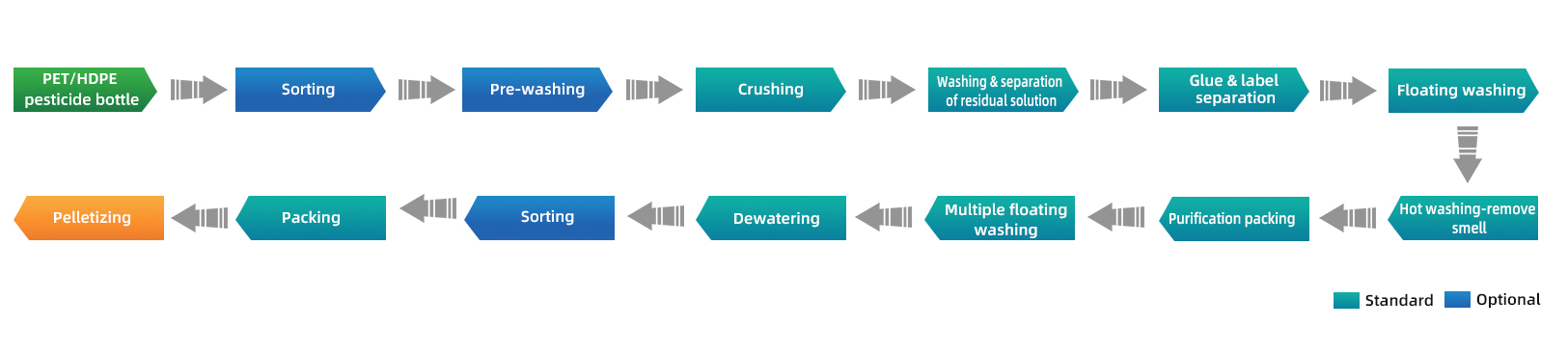

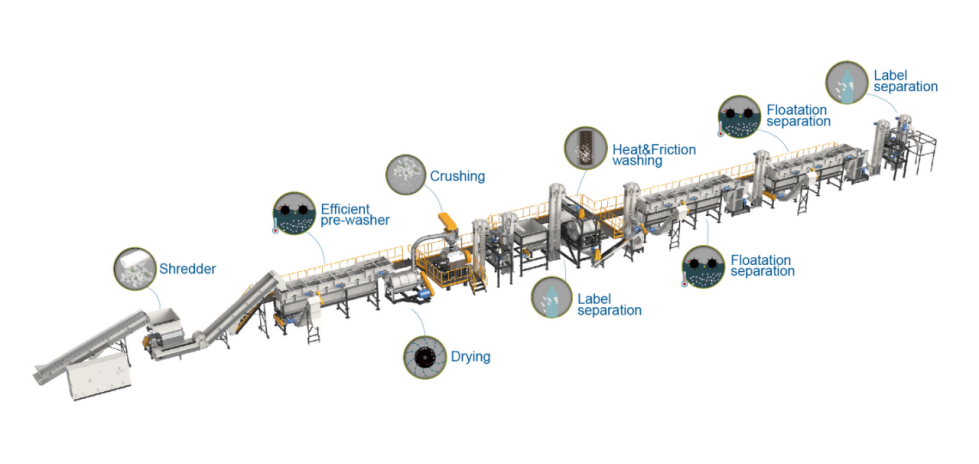

Raw materials: medical waste, PET / PE composite pesticide bottles, chemical solvents, etc

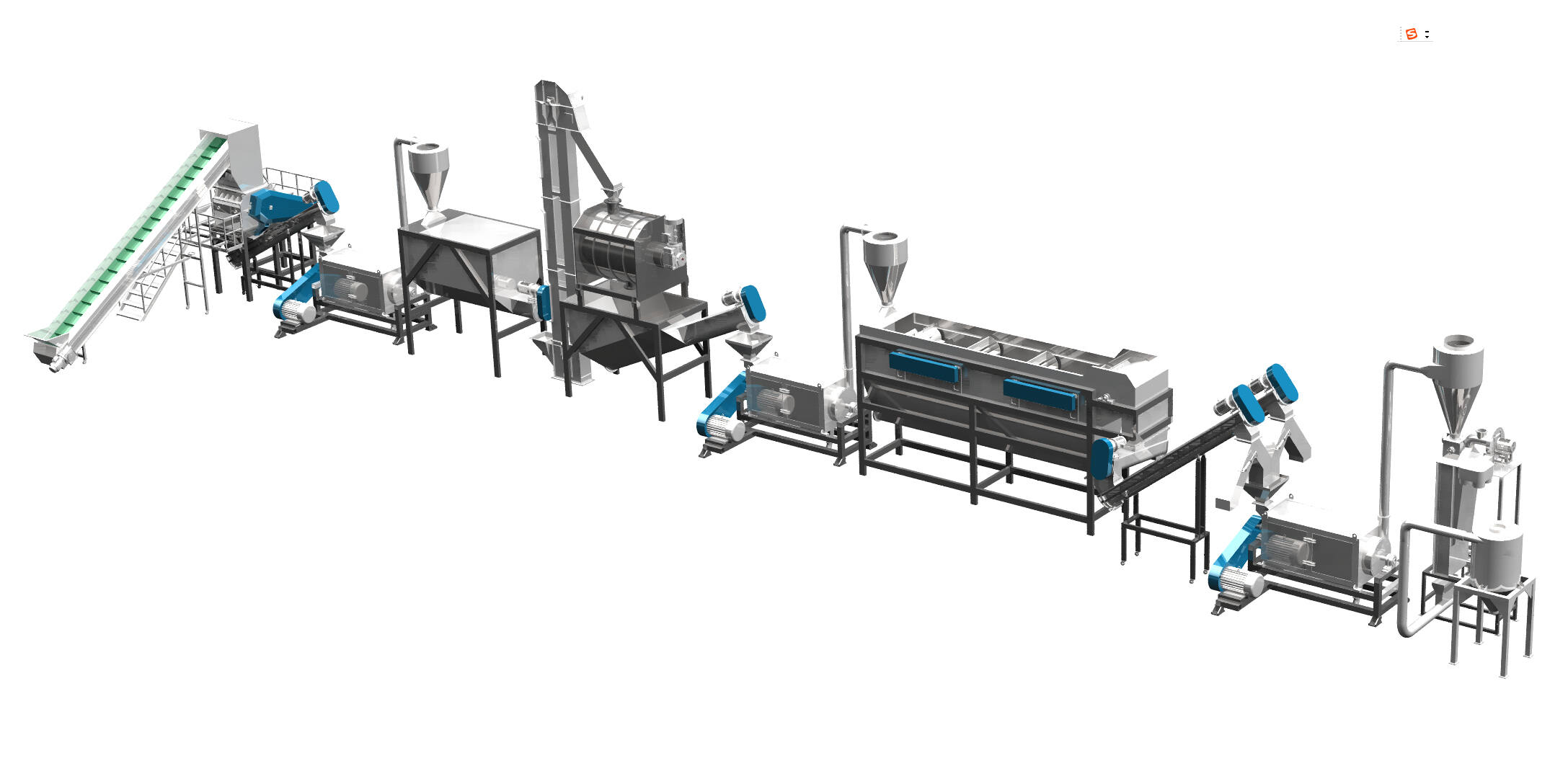

| Model | Capacity | Installation power | Space | Steam | Compressed air | water |

| PEPP500 | 500kg/h | 98kw | 150m2 | * | 0.5m3 | 2m3 |

| PEPP1000 | 1000kg/h | 150kw | 200m2 | * | 0.5m3 | 2m3 |

| PEPP2000 | 2000kg/h | 190kw | 300m2 | * | 0.5m3 | 3m3 |

| No | Name | Consumption/ton | No | Name | Consumption/ton |

| 1 | electricity | 50-80kw | 3 | Clean agent (option) | 0-3kg |

| 2 | Steam (option) | 0-100kg | 4 | water | 0.8-1.5T |