Modern plastic bottle recycling facilities face increasing pressure to maximize efficiency while maintaining high-quality output standards. The global demand for recycled materials continues to surge, making streamlined operations essential for competitive advantage. Effective workflow management in plastic bottle recycling requires careful coordination of multiple processes, from initial sorting to final product delivery. Understanding the interconnected nature of these operations enables facility managers to identify bottlenecks and implement targeted improvements that enhance overall productivity.

Foundation Elements of Efficient Recycling Operations

Strategic Layout and Equipment Positioning

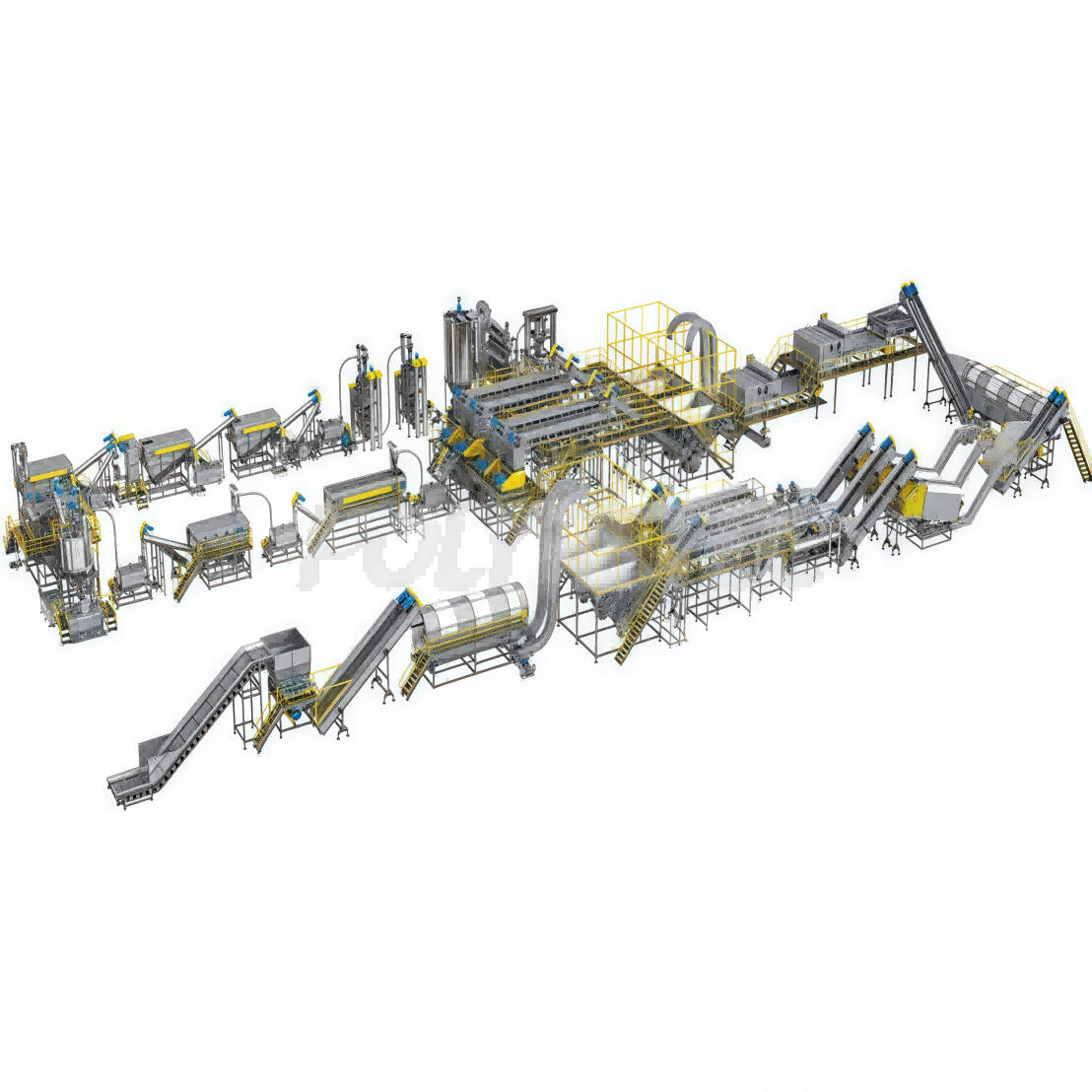

The physical arrangement of equipment and workstations directly impacts workflow efficiency in plastic bottle recycling facilities. A well-designed layout minimizes material handling distances and reduces processing time between stages. Linear flow configurations typically work best, allowing materials to move systematically from intake through sorting, cleaning, and processing without unnecessary backtracking. Strategic positioning of conveyor systems, sorting stations, and washing equipment creates smooth transitions that prevent accumulation of materials at bottleneck points.

Proper spacing between equipment allows for maintenance access while ensuring adequate room for material flow. The integration of automated systems with manual sorting stations requires careful consideration of worker safety zones and emergency access routes. Facility managers should regularly evaluate equipment positioning to identify opportunities for improved material flow patterns that reduce handling costs and processing delays.

Quality Control Integration Throughout the Process

Implementing quality control checkpoints at strategic intervals prevents contaminated materials from progressing through expensive downstream processes. Early detection of unsuitable materials saves significant processing costs and reduces equipment wear. Quality control stations should be positioned after initial sorting, following washing processes, and before final pelletization to ensure consistent output quality.

Training quality control personnel to recognize various contamination types enables rapid decision-making that maintains process flow. Documentation of quality metrics at each checkpoint provides valuable data for identifying trends and implementing preventive measures. Regular calibration of detection equipment ensures reliable performance standards across all quality control stations.

Advanced Sorting and Preparation Methods

Multi-Stage Sorting Systems

Contemporary plastic bottle recycling operations benefit from sophisticated sorting technologies that improve material purity and processing speed. Optical sorting systems can identify different plastic types, colors, and contamination levels with remarkable accuracy. Near-infrared spectroscopy enables automated separation of PET bottles from other plastic materials, significantly reducing manual labor requirements while improving consistency.

Density separation techniques complement optical sorting by removing labels and caps that may have similar optical properties to bottle materials. Air classification systems effectively separate lightweight contaminants from heavier plastic components. The combination of multiple sorting technologies creates comprehensive material preparation that enhances downstream processing efficiency and final product quality.

Contamination Removal Strategies

Effective contamination removal begins with proper pre-sorting protocols that eliminate obviously unsuitable materials before they enter processing equipment. Labels, adhesives, and caps represent common contaminants that can interfere with plastic bottle recycling processes. Hot wash systems designed specifically for removing adhesive residues prevent contamination of final recycled products.

Caustic washing solutions effectively remove organic contaminants while maintaining plastic integrity. Multiple rinse cycles ensure complete removal of cleaning agents that could affect recycled material properties. Proper drainage and drying systems prevent water contamination that can degrade final product quality and create processing complications in downstream applications.

Processing Efficiency Optimization

Temperature and Chemical Management

Precise control of washing temperatures and chemical concentrations significantly impacts both processing efficiency and final product quality in plastic bottle recycling systems. Optimal temperature ranges vary depending on contamination types and plastic specifications. Too low temperatures may result in incomplete contamination removal, while excessive heat can degrade plastic properties or increase energy costs unnecessarily.

Chemical dosing systems should be automated to maintain consistent concentrations throughout processing cycles. Regular monitoring of solution effectiveness prevents overuse of expensive chemicals while ensuring adequate cleaning power. Proper chemical recovery and recycling systems reduce operating costs and minimize environmental impact from processing operations.

Water Management and Recycling

Water consumption represents a significant operational cost in plastic bottle recycling facilities, making efficient water management essential for sustainable operations. Closed-loop water systems capture and treat process water for reuse, dramatically reducing fresh water requirements. Filtration and clarification systems remove suspended solids and contaminants from recirculated water.

Strategic water usage planning ensures that clean water is reserved for final rinse operations while recycled water handles initial washing stages. Proper water temperature management throughout the system maintains cleaning effectiveness while optimizing energy consumption. Regular monitoring of water quality parameters prevents contamination buildup that could affect processing efficiency or final product specifications.

Automation and Technology Integration

Process Control Systems

Modern plastic bottle recycling facilities increasingly rely on sophisticated process control systems that monitor and adjust operational parameters in real-time. These systems track material flow rates, equipment performance, and quality metrics to optimize overall facility efficiency. Automated feedback loops adjust processing parameters based on material characteristics and quality requirements.

Integration of sensors throughout the processing line provides continuous data on material properties, contamination levels, and equipment performance. Predictive maintenance algorithms analyze sensor data to identify potential equipment issues before they cause production disruptions. Comprehensive data logging enables facility managers to identify optimization opportunities and track improvement initiatives over time.

Material Handling Automation

Automated material handling systems reduce labor costs while improving consistency in plastic bottle recycling operations. Robotic sorting systems can work continuously without fatigue, maintaining steady throughput rates throughout extended operating periods. Automated conveyor systems with variable speed controls optimize material flow based on downstream capacity and processing requirements.

Programmable logic controllers coordinate material movement between processing stages, preventing accumulation at bottleneck points. Automated storage and retrieval systems manage inventory of sorted materials and finished products efficiently. Integration of material handling automation with process control systems creates seamless operations that respond dynamically to changing conditions and requirements.

Maintenance and Reliability Management

Preventive Maintenance Scheduling

Systematic preventive maintenance programs are crucial for maintaining consistent performance in plastic bottle recycling facilities. Regular inspection schedules should address wear components, lubrication requirements, and cleaning procedures for all processing equipment. Properly maintained equipment operates more efficiently and produces higher quality recycled materials.

Maintenance scheduling should consider production demands and peak operating periods to minimize disruption to processing operations. Critical spare parts inventory management ensures rapid repair capabilities when equipment failures occur. Documentation of maintenance activities provides valuable data for optimizing maintenance intervals and identifying recurring issues that may require design modifications.

Equipment Performance Monitoring

Continuous monitoring of equipment performance parameters enables early detection of degradation that could affect processing efficiency. Vibration analysis, temperature monitoring, and power consumption tracking provide insights into equipment condition and performance trends. Establishing baseline performance metrics enables identification of gradual degradation that might otherwise go unnoticed.

Performance monitoring systems should generate alerts when parameters exceed acceptable ranges, enabling prompt corrective action. Regular analysis of performance data helps identify opportunities for operational improvements and equipment upgrades. Integration of performance monitoring with maintenance scheduling creates comprehensive asset management that maximizes equipment reliability and productivity.

Workflow Documentation and Continuous Improvement

Standard Operating Procedures

Comprehensive documentation of all operational procedures ensures consistent performance regardless of staffing changes in plastic bottle recycling facilities. Standard operating procedures should cover normal operations, quality control requirements, and emergency response protocols. Regular updates to procedures reflect process improvements and lessons learned from operational experience.

Training programs based on documented procedures ensure all personnel understand their roles in maintaining efficient operations. Visual aids and process flowcharts help workers quickly understand complex procedures and identify potential issues. Regular review and testing of procedures ensures they remain current and effective for actual operating conditions.

Performance Metrics and Analysis

Establishing key performance indicators enables objective evaluation of facility efficiency and identification of improvement opportunities. Throughput rates, quality metrics, energy consumption, and material recovery rates provide comprehensive insight into operational performance. Regular analysis of performance trends helps identify areas where focused improvement efforts can yield significant results.

Benchmarking against industry standards and best practices provides context for performance evaluation and goal setting. Employee involvement in performance monitoring and improvement initiatives creates ownership and accountability for operational excellence. Systematic documentation of improvement initiatives enables sharing of successful practices across multiple facilities or shifts.

FAQ

What are the most critical factors for optimizing plastic bottle recycling workflow efficiency?

The most critical factors include proper equipment layout to minimize material handling distances, implementation of multi-stage sorting systems for improved material purity, effective contamination removal processes, and integration of automation technologies. Additionally, maintaining optimal processing parameters such as temperature and chemical concentrations, along with comprehensive preventive maintenance programs, significantly impact overall workflow efficiency. Quality control integration at strategic checkpoints prevents expensive downstream processing of unsuitable materials.

How can facilities reduce operational costs while maintaining processing quality?

Cost reduction strategies include implementing closed-loop water recycling systems to minimize fresh water consumption, optimizing chemical usage through automated dosing systems, and utilizing energy-efficient equipment with proper temperature management. Preventive maintenance programs reduce unexpected downtime and repair costs while extending equipment life. Strategic automation of material handling and sorting processes reduces labor costs while improving consistency. Regular performance monitoring identifies inefficiencies that can be addressed through targeted improvements rather than expensive equipment replacements.

What role does technology play in modern plastic bottle recycling operations?

Technology integration is essential for competitive plastic bottle recycling operations, providing automated sorting capabilities through optical systems and near-infrared spectroscopy. Process control systems monitor real-time parameters and adjust operations automatically for optimal performance. Predictive maintenance technologies analyze equipment data to prevent failures and optimize maintenance scheduling. Material handling automation coordinates workflow between processing stages while reducing labor requirements and improving consistency.

How can facilities ensure consistent quality output while maximizing throughput?

Consistent quality requires strategic placement of quality control checkpoints throughout the processing line, comprehensive training of quality control personnel, and regular calibration of detection equipment. Implementing standard operating procedures with regular updates based on operational experience ensures consistent performance. Multi-stage sorting and contamination removal processes improve input material quality, reducing variability in final products. Process control systems maintain optimal operating parameters automatically, while performance monitoring identifies trends that could affect quality before they impact production.

Table of Contents

- Foundation Elements of Efficient Recycling Operations

- Advanced Sorting and Preparation Methods

- Processing Efficiency Optimization

- Automation and Technology Integration

- Maintenance and Reliability Management

- Workflow Documentation and Continuous Improvement

-

FAQ

- What are the most critical factors for optimizing plastic bottle recycling workflow efficiency?

- How can facilities reduce operational costs while maintaining processing quality?

- What role does technology play in modern plastic bottle recycling operations?

- How can facilities ensure consistent quality output while maximizing throughput?