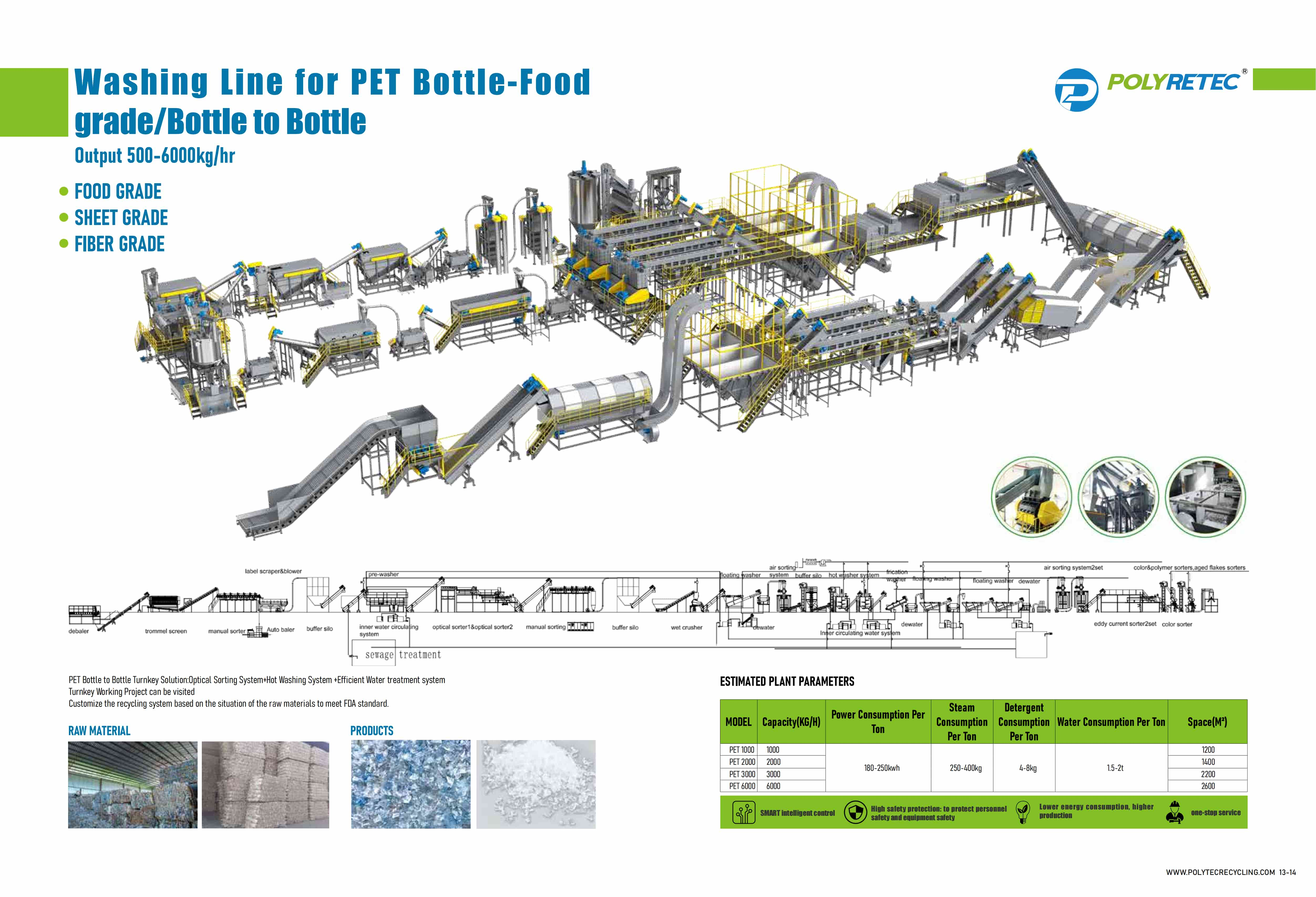

Raw materials: Beverage bottles, mineral water bottle, food bottles/jars (salad dressing, peanut butter, honey, etc.).

| Input capacity (kg/h) | Required area(㎡) | Install power | Required water | Required steam | Required compressor air(㎡/min) | Man power |

| (kw) | (m³/h) | (kg/h) | ||||

| 1000 | 1300 | 550 | 2 | 600 | 3 | 5 |

| 2000 | 1600 | 800 | 4 | 900 | 4.5 | 7 |

| 3000 | 2000 | 900 | 4.5 | 1300 | 6.5 | 8 |

| 6000 | 3000 | 1000 | 9 | 2300 | 12 | 11 |

| Input capacity (kg/h) | Electricity consumption | Steam | Washing detergent | Water consumption |

| (KWH) | (kg) | (kg) | (ton) | |

| 1000 | 170 | 600 | 12 | 1.5 |

| 2000 | 165 | 550 | 12 | 1.5 |

| 3000 | 160 | 500 | 12 | 1.5 |

| 6000 | 150 | 450 | 12 | 1.5 |

| Moisture | <1% |

| Label | <15ppm |

| Pvc | <30ppm |

| Inorganic compounds | <10ppm |

| Glue | <10ppm |

| PH | 7.5±0.5 |

| PP/PE | <15ppm |

| Metal | <10ppm |

| Total impurity | <100ppm-250ppm |

| *Flake size | 12mm |

| unpacking machine | When working, a forklift is used to place the bottle bricks on the platform, manually cut and pull out the strapping iron wire, and then the forklift pushes the bottle bricks into the rubber belt conveyor for transportation, and the unpacking speed is controlled by frequency conversion and speed regulation. |  |

| Trommel screen |

The effect is to break up the lumps, sift out small garbage and part of the bottle cap.

|

|

| Pre-washer | It aims to wash away the dirt and adhesive labels on the surface of bottle scraps that are delivered to the washing machine after being scattered by the unpacking machine with high-temperature agentia to and deliver the washed bottles to the next process with the double screw. |  |

| Label Scrapping machine | The label scrapping machine is designed to scrap the labels attached to bottles. It mainly consists of feed section, rotor drum, nail tray, pedestal, lateral plate, discharge section and transmission device |  |

| Label blower | Due to the weight difference between bottles and labels, labels are separated out by the wind force of the label blowing fan that is equipped to the discharge end of the drum of the blowing machine, brought into the label screen frame and collected by the trolley or blown to the wrapping machine; while bottles are outputted from the other end and delivered to the next process by the double-screw conveyor. |  |

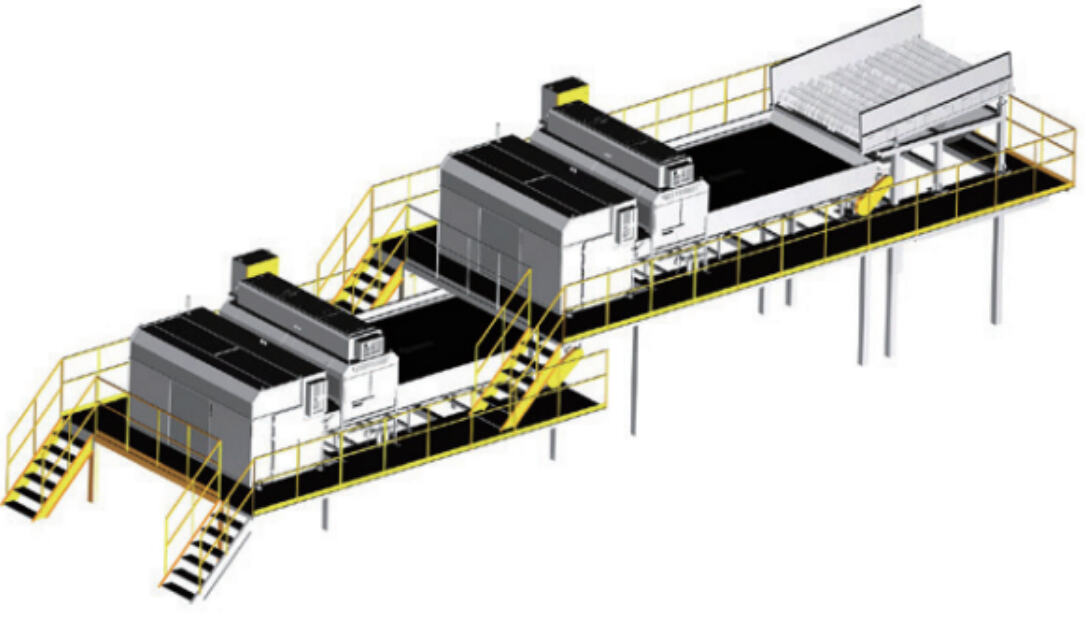

| Optical bottle sorting section |

Polyretec provides optical sorting machine and integraton Solution by cooperating with well-known sorting device manufacturers across the world.On one hand,automatic opticalsorting macthine can reduce the mananement cost and man power requirement and on the other hand guaranteeing the stablity of sorting. Non-PET color bottles and metals can be detected and sorted out by NIR.optical sensor optical camera and metal detector in this section.lt provides guarantee the PET materials purity. |

|

| Wet Crusher | Wet grinding featured with unhindered feeding, stable output, low energy consumption, low noise, and firm structure is adopted in this production line |

|

| Floating Washer | Remove caps,dust ,stone ,impurities ,chemicals |   |

| Zig-zag label blower |

Removing label dust ,labels,powder Maximum separation efficiency ~99% -Target PVC label content <10PPM Depend on local raw material characteristics(thickness,label type) |

|

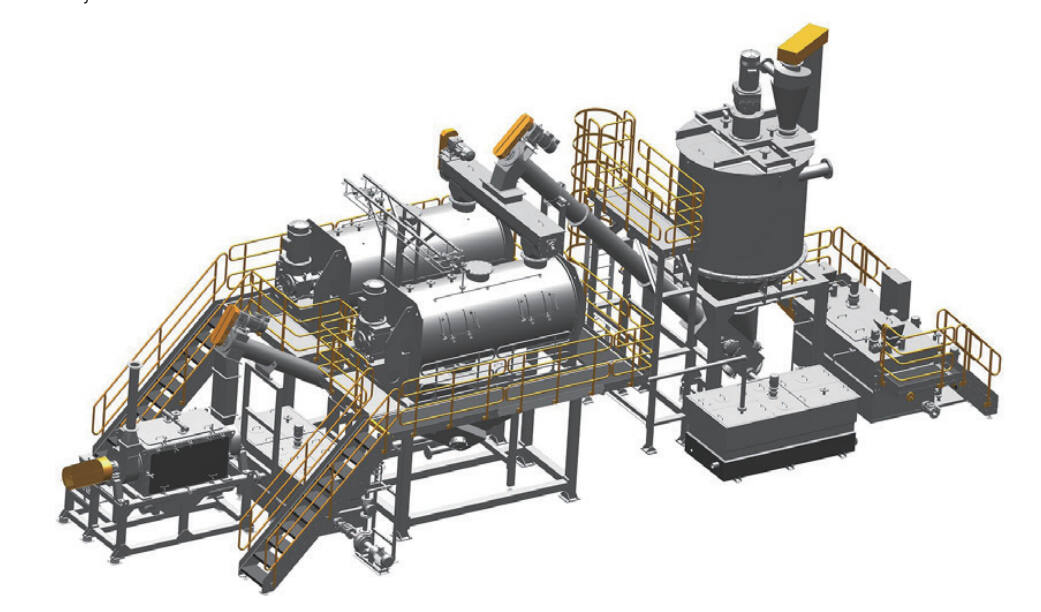

| Hot washer section |

Smart control washing process Smart chemical dosing feeder Smart adding flakes and come out Smart injecting steam water Smart set heating time |

|

| Centrifugal Dewater |

Removing water and dry flakes into 1% Efficient aspiration guarantees high quality,cleaning-free mesh saves manpower Driven by the shaft of the de-watering machine,the rPET flakes reacha high-speed centrifugal state within the chamber,effectively removing water through the mesh. |

|

|

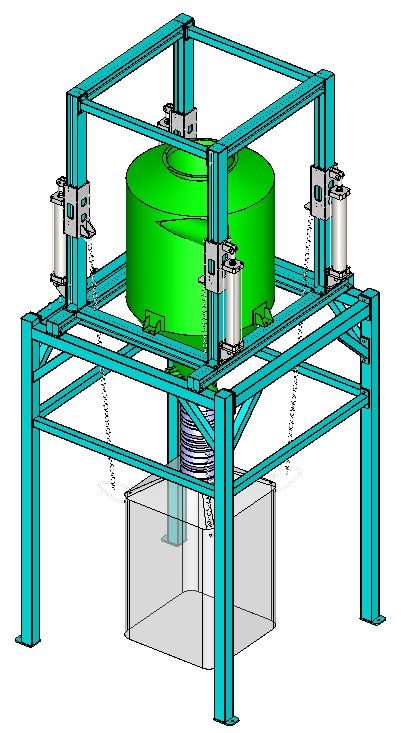

Flakes sorting , blending and packing section |

For high-grade PET flakes applications,automatic optical flake sorting unit is an indispensable module.the unit including automatic flake sorting eddy curent.and pipe-type metal separator.These devices would maximize the removal of impurities before packing to ensure the stability of flakes quality.Flake with low impurity content and stable quality is a standard to measure PET recycling process.For the various quality factors during PET recyclingprocess,blending equipment and on-ine detection device especially designed can ensure the various quality indicators to meet criteria and to make sure nosinale parameter exceedino the reauirementso thatthe uality ofthe flakes wilbe quaranteed.0n-line weighing device can monitor real-time production flow.Packing unit by taking advantage of the shaking system specially designed,can make the packing of the flakes reach the fix weight and maximize bulk density which areatly reduce the packing and transportation costs. |  |

| Online circulating water filtration system | It is composed of water pump, circular vibration sieve and water tank. the water discharged from the machine is filtered out of labels and caps.The water is then sent to the next level of machine for use. | |

| Vibrating packing Silo |

Effective volume: 1.5m³ Hydraulic lifters |

|

| DCS intelligent recycling line control system |

Upper computer control system: Features: ①The production process is controlled in real time, and data .② Monitor the operating status of the equipment in real time③The system is equipped with an intelligent medical examination module to remind the equipment of regular inspection items in real time to avoid false or missed inspections. |

|

| All type of bearings use Japanese NSK or German SKF, |  |

| The motor is SIEMENS or WEG |  |

| The reducer adopts Ruidesen |  |

| Inverter |  |

| Low voltage components |  |

| PLC Module |  |

| Imported conductivity sensor is used for hot washing detection | |

| DCS SYTEM |  |