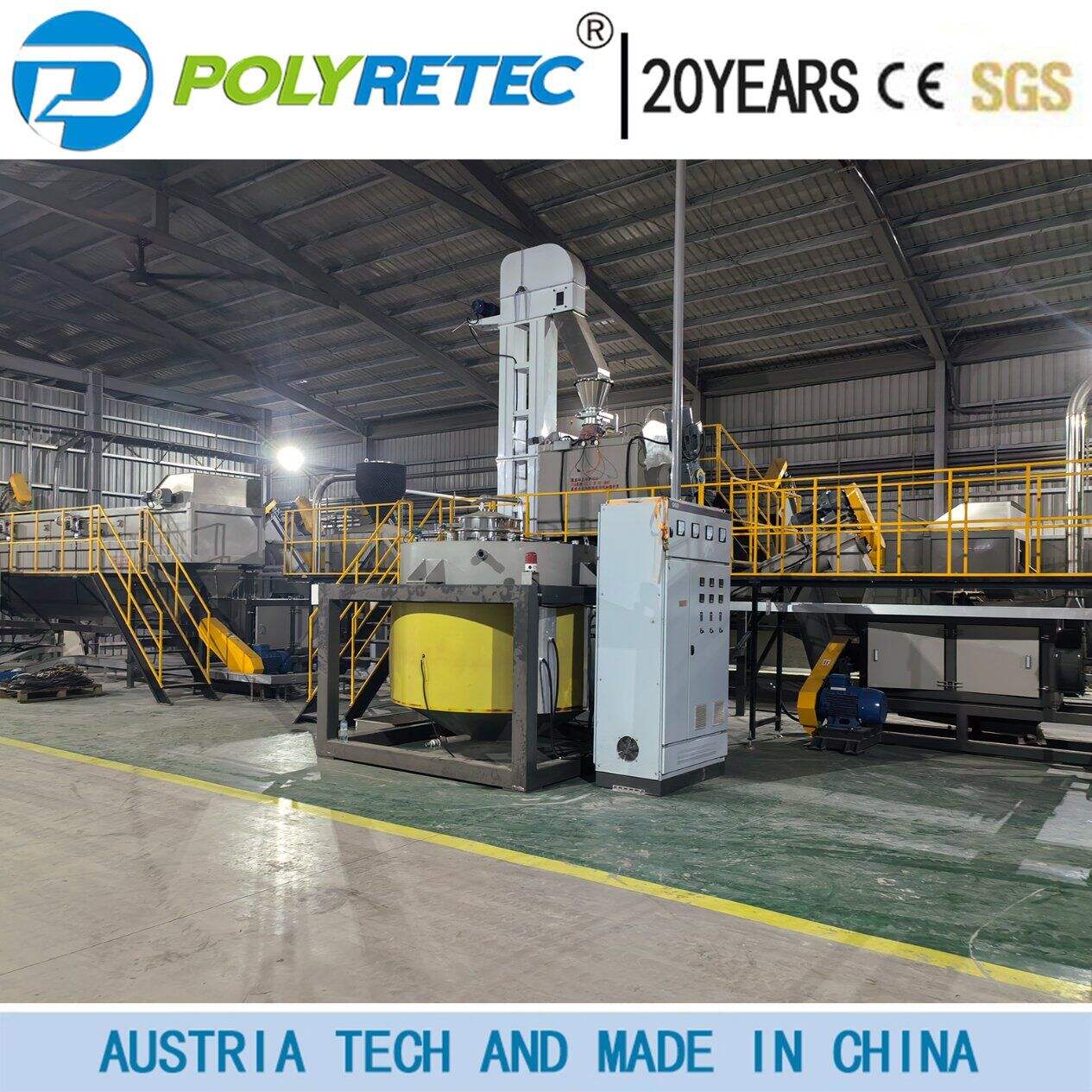

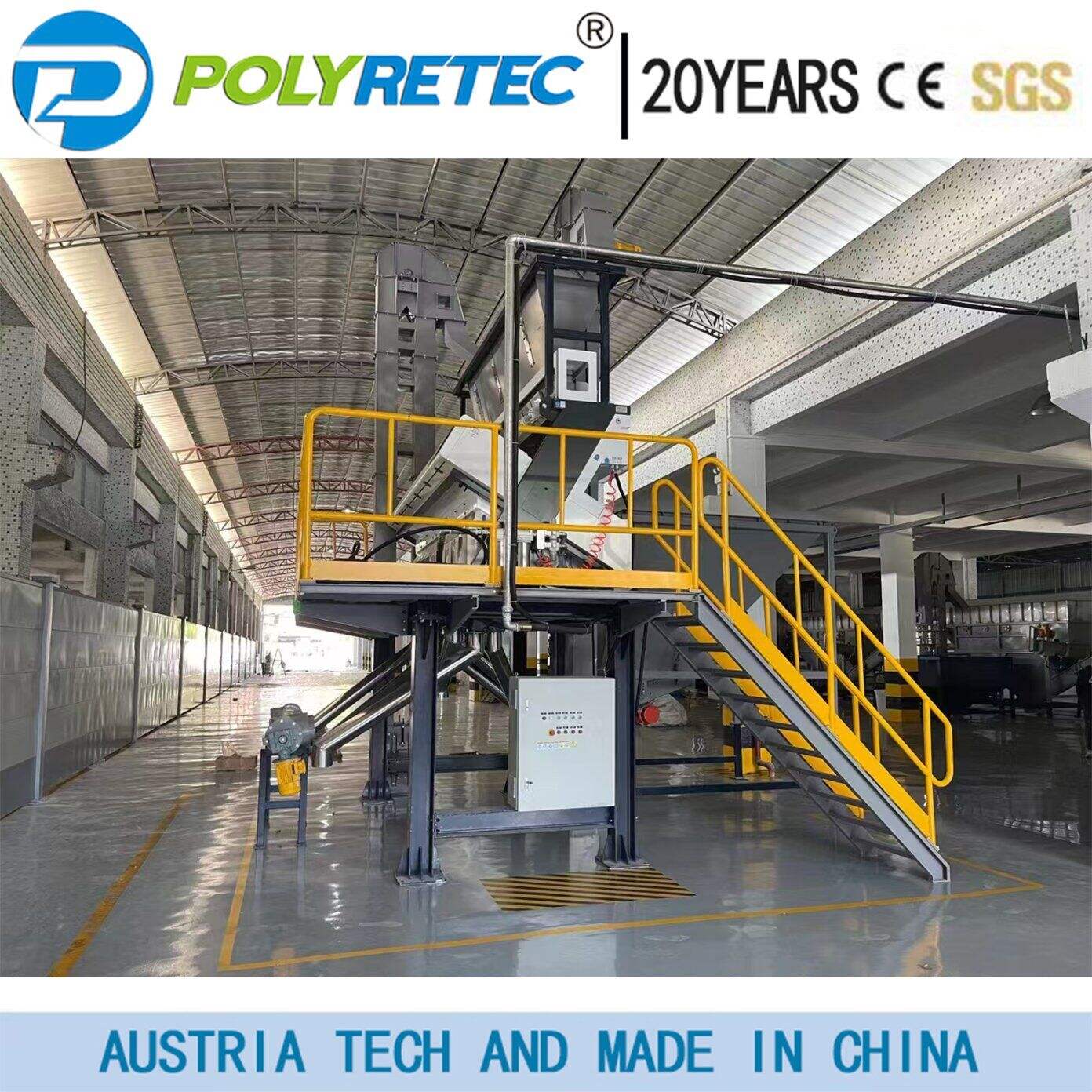

pet bottle to bottle recycling plant

A PET bottle to bottle recycling plant represents a state-of-the-art facility designed to transform used PET bottles into food-grade recycled materials suitable for new bottle production. This advanced system incorporates multiple stages of processing, including sorting, grinding, washing, and decontamination to ensure the highest quality output. The plant utilizes cutting-edge technologies such as automated sorting systems with NIR sensors, hot washing processes, and advanced extrusion equipment to convert post-consumer PET bottles into clean, food-grade flakes or pellets. The facility's sophisticated decontamination process removes all contaminants and ensures compliance with FDA and EFSA standards for food-contact materials. With processing capabilities ranging from 1,000 to 20,000 kg per hour, these plants serve various industrial scales. The system's efficient design minimizes energy consumption while maximizing yield, typically achieving recovery rates of up to 85%. Modern plants also incorporate water recycling systems and energy recovery mechanisms, making them environmentally sustainable. The output material meets stringent quality requirements for bottle-grade PET, enabling closed-loop recycling in the beverage industry.