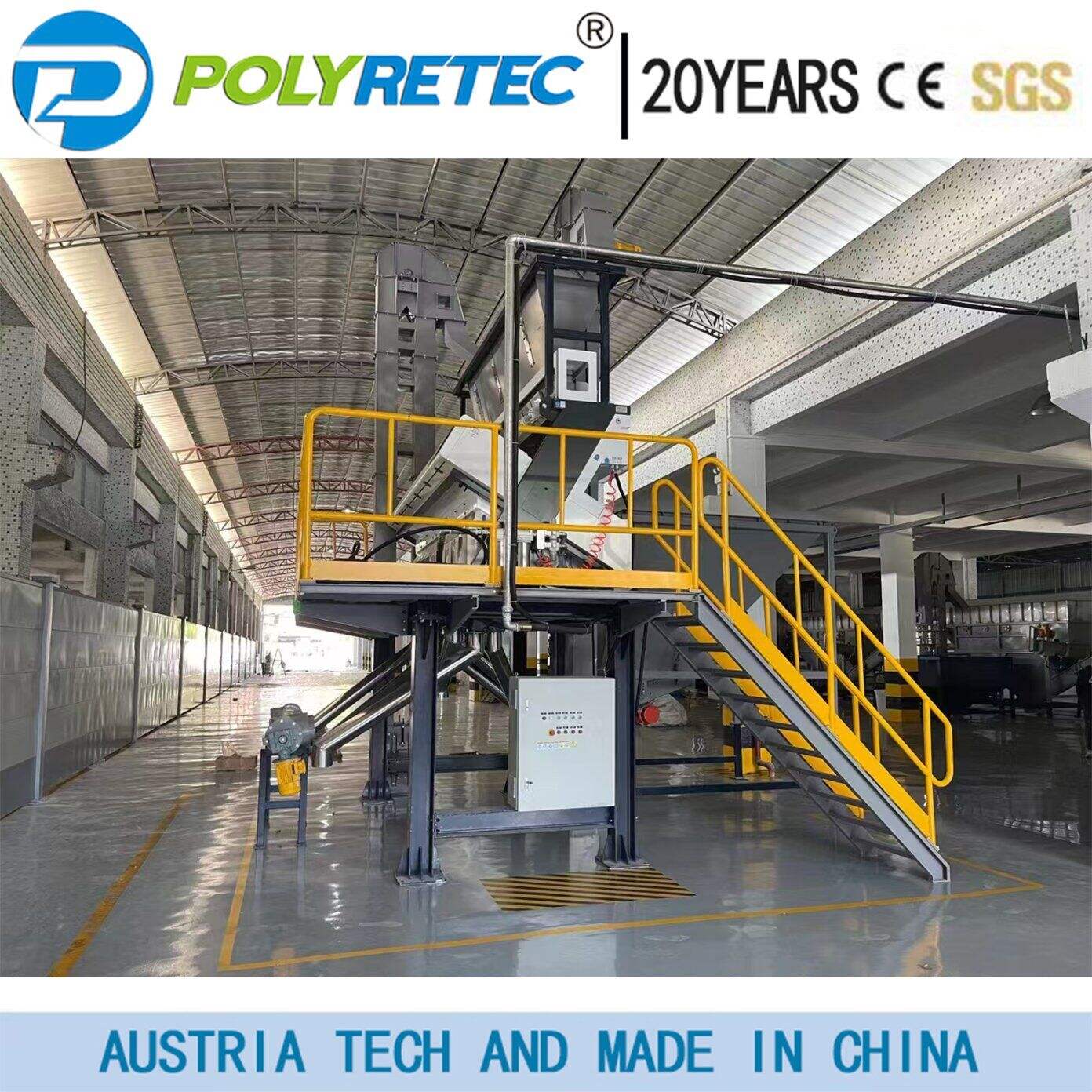

bottle recycling plant

A bottle recycling plant represents a state-of-the-art facility designed to transform used bottles into valuable recycled materials through an efficient, automated process. The plant incorporates advanced sorting mechanisms, washing systems, and granulation technology to process various types of bottles, primarily PET and HDPE materials. At its core, the facility operates through multiple stages: initial sorting using optical sensors and automated systems to separate bottles by material and color, followed by a thorough cleaning process that removes labels, caps, and contaminants. The materials then undergo size reduction through industrial shredders, creating uniform flakes that are further cleaned and processed. Modern bottle recycling plants feature advanced contamination detection systems, ensuring the highest quality output. The facility typically processes several tons of bottles per hour, utilizing energy-efficient systems and water conservation measures. The final output includes clean, sorted plastic flakes or pellets ready for remanufacturing into new products. These plants often incorporate real-time monitoring systems and quality control measures throughout the process, ensuring consistent output quality. The facility's design typically allows for future upgrades and capacity expansions, making it a sustainable long-term investment for waste management operations.