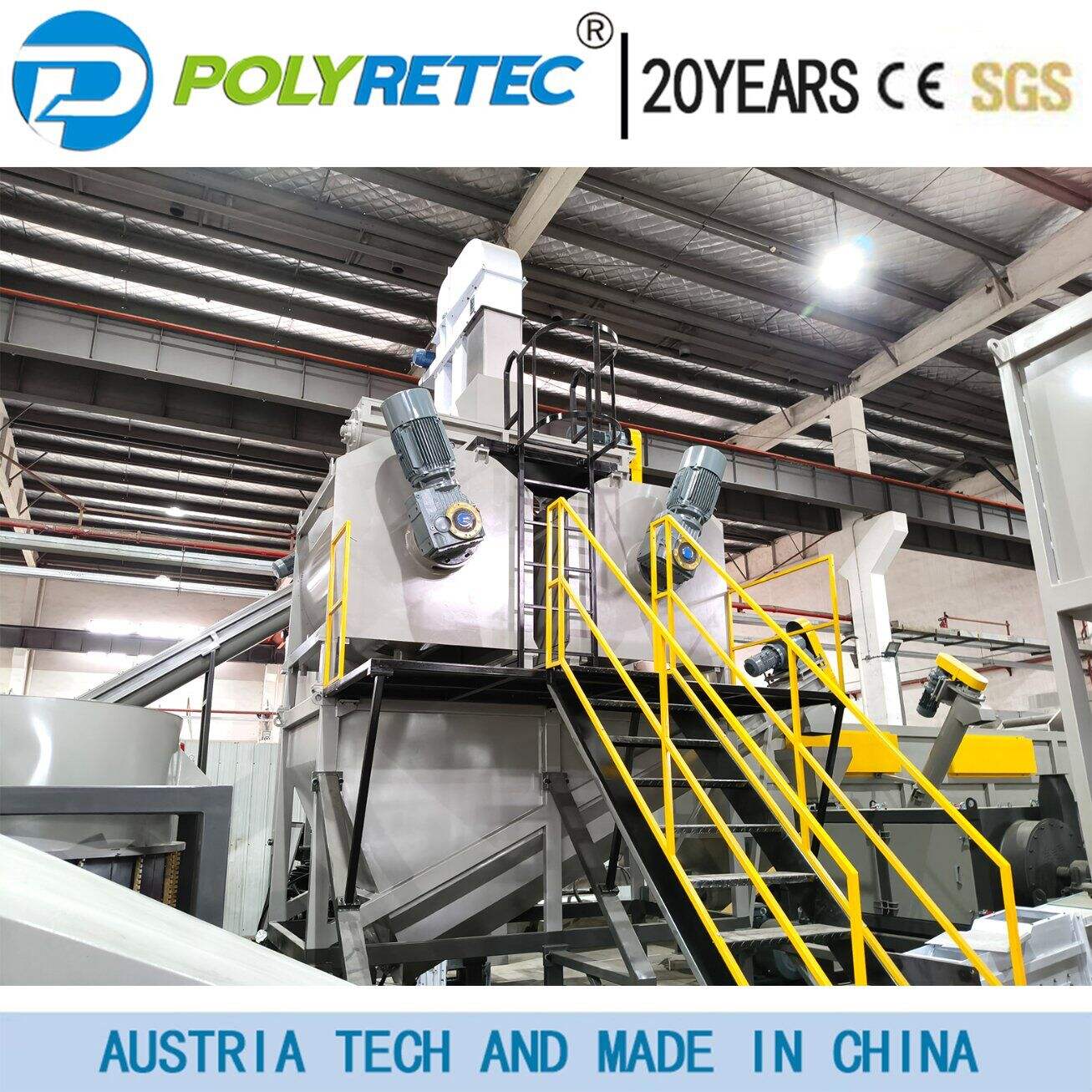

pet bottle scrap recycling plant

A pet bottle scrap recycling plant represents a cutting-edge solution for transforming used PET bottles into valuable recycled materials. This sophisticated facility incorporates advanced sorting mechanisms, washing systems, and processing equipment to handle large volumes of post-consumer PET waste efficiently. The plant operates through a series of integrated stages, beginning with automated sorting that separates PET bottles from other materials using optical sensors and air classification systems. The bottles then undergo a thorough cleaning process, removing labels, caps, and contaminants before being shredded into flakes. These flakes are subjected to a flotation separation process that ensures the highest purity levels of the final product. The plant's advanced technology includes hot washing systems that eliminate adhesives and organic residues, followed by state-of-the-art drying and crystallization processes. The final output consists of high-quality PET flakes suitable for various applications, from textile fiber production to food-grade packaging materials. With processing capacities ranging from 500 kg to several tons per hour, these plants can be customized to meet specific production requirements while maintaining consistent output quality.