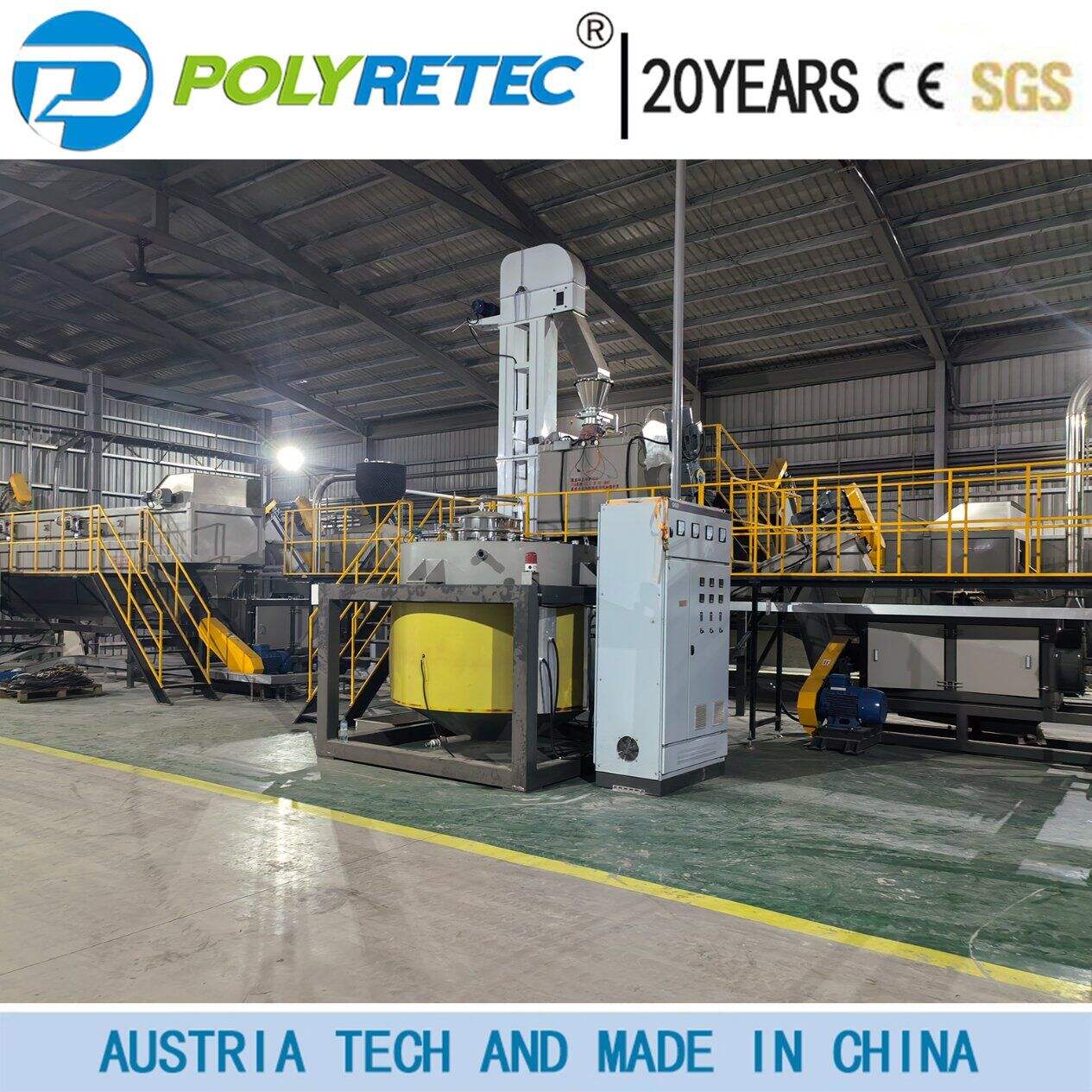

plastic bottle recycling plant

A plastic bottle recycling plant represents a cutting-edge solution for processing post-consumer PET bottles into valuable recycled materials. The facility incorporates advanced sorting systems, washing lines, and granulation equipment to transform waste bottles into high-quality recycled plastic pellets. The plant operates through multiple stages, beginning with automated sorting mechanisms that separate PET bottles from other materials using optical sensors and air classification technology. The bottles then undergo a thorough cleaning process, removing labels, caps, and contaminants through hot washing and friction washing systems. After cleaning, the material passes through precision shredding equipment, creating uniform flakes that are further processed through flotation tanks to ensure maximum purity. The final stage involves advanced extrusion systems that convert the cleaned flakes into recycled plastic pellets suitable for various manufacturing applications. Modern plants typically feature fully automated control systems, real-time monitoring capabilities, and energy-efficient components that optimize operational costs while maintaining high output quality. These facilities can process several tons of plastic bottles per hour, contributing significantly to environmental sustainability while creating valuable raw materials for industrial use.