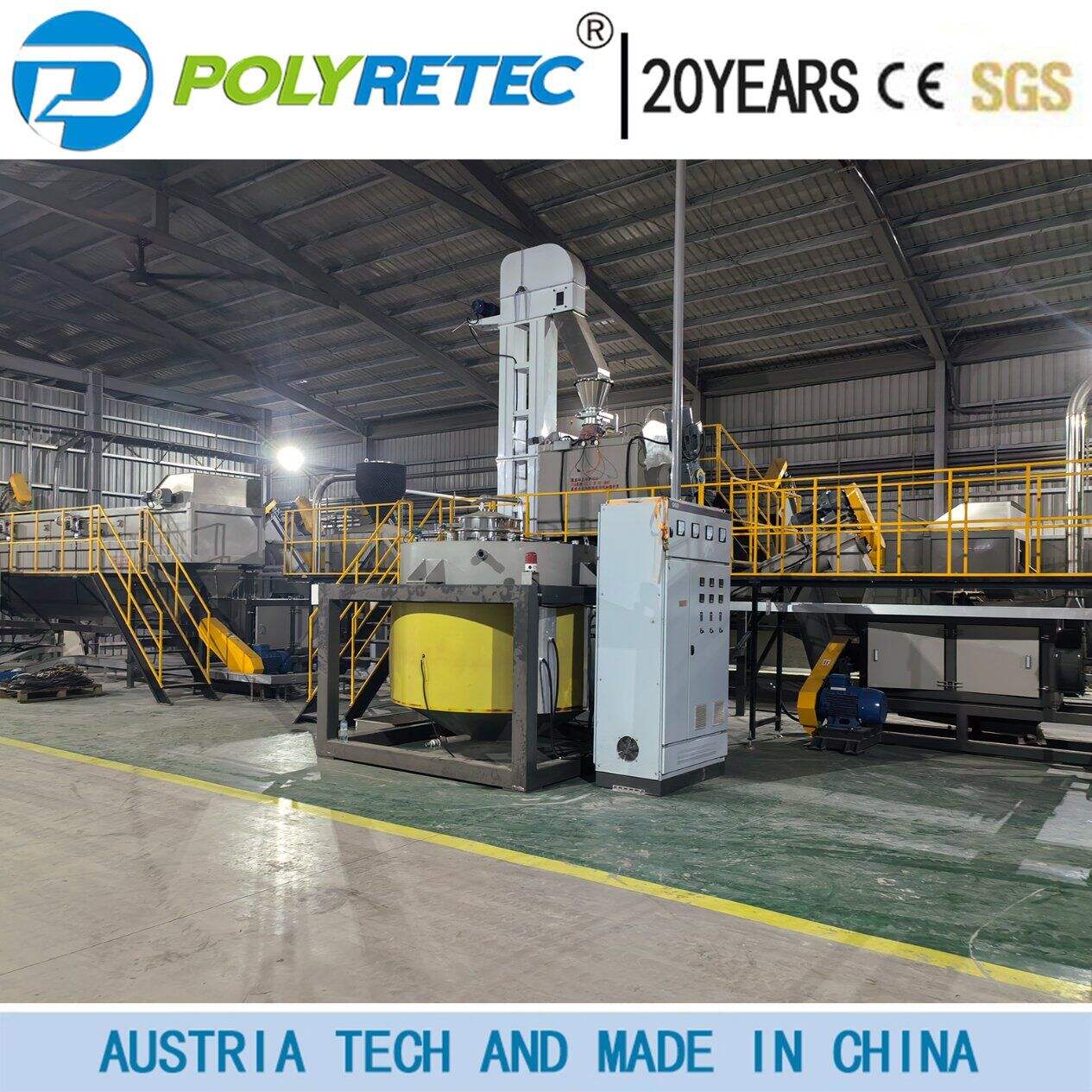

pet bottle recycling plant

A pet bottle recycling plant represents a cutting-edge solution for transforming used PET bottles into valuable recycled materials. This advanced facility incorporates multiple processing stages, including sorting, grinding, washing, and pelletizing, to convert waste plastic bottles into high-quality recycled PET flakes or pellets. The plant utilizes automated sorting systems equipped with optical sensors to separate PET bottles from other materials, ensuring maximum purity in the final product. The grinding system reduces bottles to uniform-sized flakes, while the washing process removes contaminants, labels, and adhesives. Advanced hot washing technology ensures thorough cleaning of the materials, while the sophisticated drying system prevents moisture-related issues in the final product. The plant's pelletizing system transforms clean flakes into uniform pellets suitable for various manufacturing applications. Modern pet bottle recycling plants typically process 500-10,000 kg per hour, depending on their scale, and incorporate energy-efficient systems to minimize operational costs. Quality control measures, including automated inspection systems and laboratory testing facilities, ensure the output meets international standards for recycled PET materials.