|

|

| PE/PP Printed roll / film | Printing waste bag |

|

|

| Pre-washed scraps | Waste Film |

|

|

| Stretch film | |

|

|

| BOPP film | HDPE/PP fiber |

|

|

| Printing woven bag | FIBC bag |

|

|

| Silk, Pumping yarn,Fiber |

| Model | PTCS80 | PTCS100 | PTCS130 | PTCS150 | PTCS185 |

| Screw diameter(mm) | 80 | 100 | 130 | 150 | 185 |

| L/D | 18-42 | ||||

| Rotating speed | 10-150 | ||||

| (rpm) | |||||

| Capacity(kg/h) | 150-250 | 200-350 | 450-600 | 600-700 | 800-1200 |

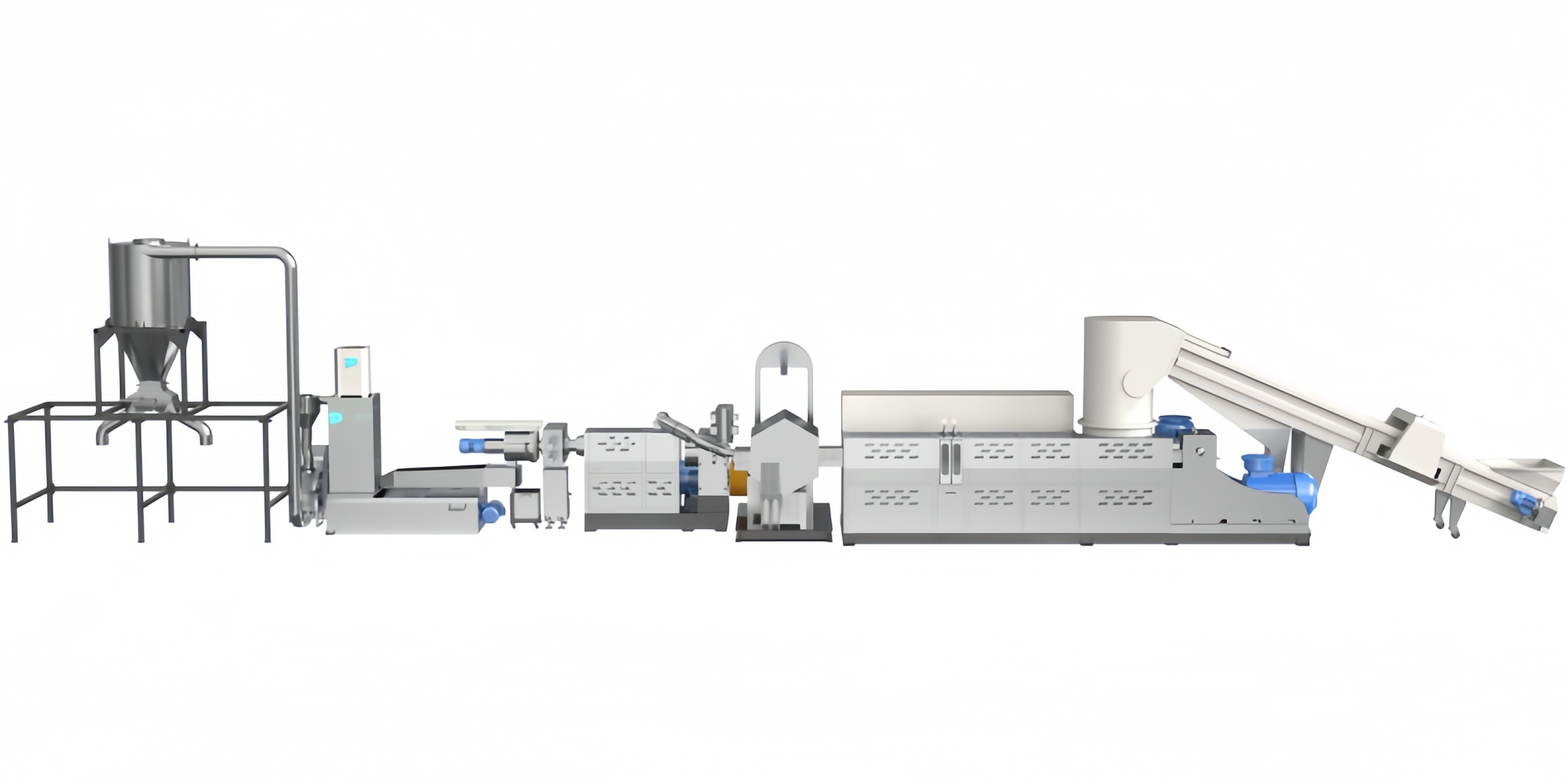

| Model | PTCS Three-in-one plastic recycling machine |

| Final product | Plastic pellets |

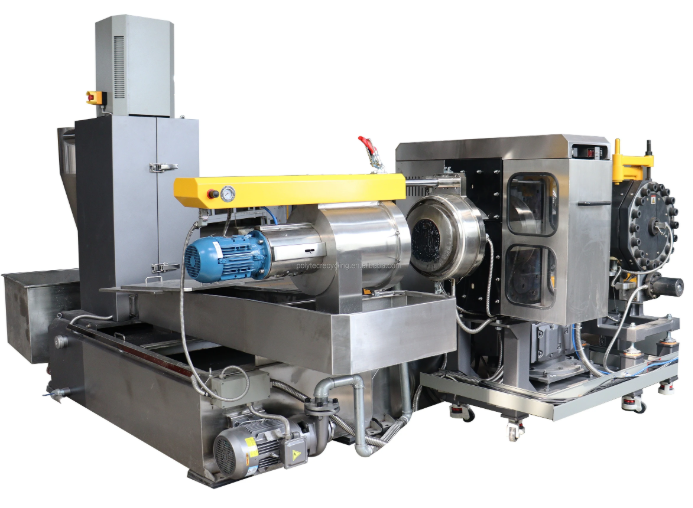

| Recycling machine structure | Conveyor belt, crusher, extruder, pelletizing unit, water cooling unit, drying unit and storage cylinder, degassing unit, filter unit |

| Recyclable materials | DPE, LDPE, LLDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, EPS |

| Production capacity | 100-1200KG/H |

| Feeding system | Belt conveyor, clamp wheel set (optional) |

| Screw diameter | 65~185mm (customized) |

| Screw length to diameter(L/D)ratio | 30/1, 32/1, 34/1, 36/1 (customized) |

| Screw material | 38CrMoAl or bimetal |

| Degassing hole | Double degassing hole, single degassing hole or no degassing hole (customized) |

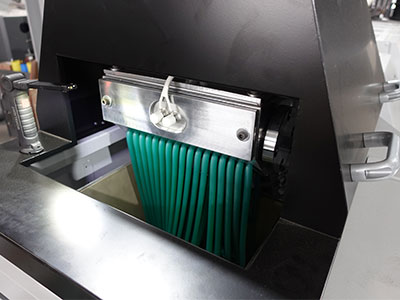

| Filtering system | Double-cylinder filtration |

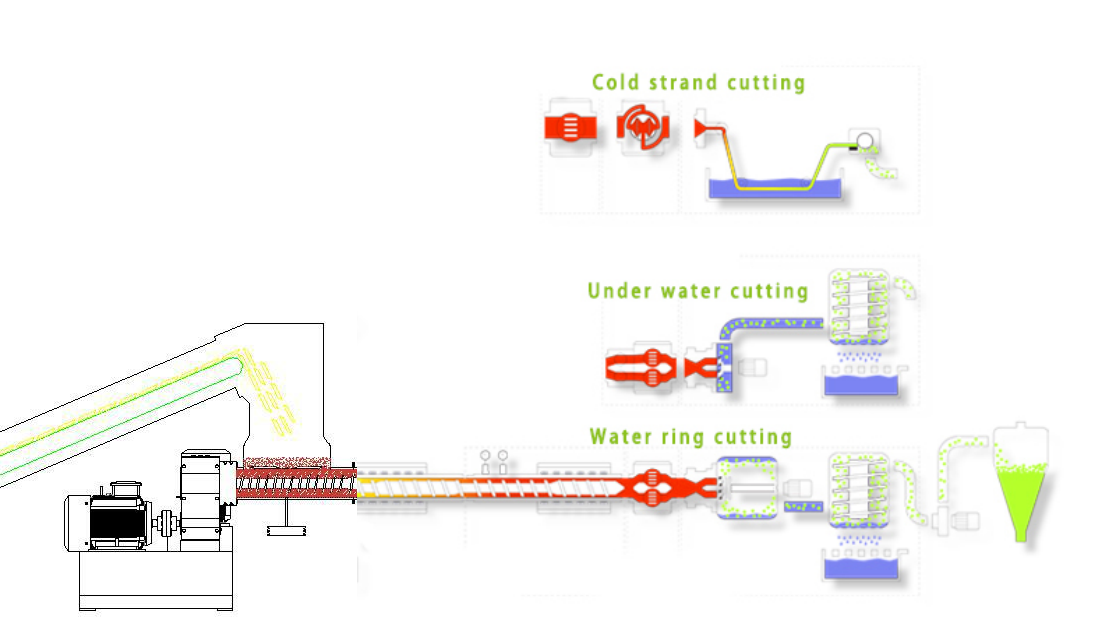

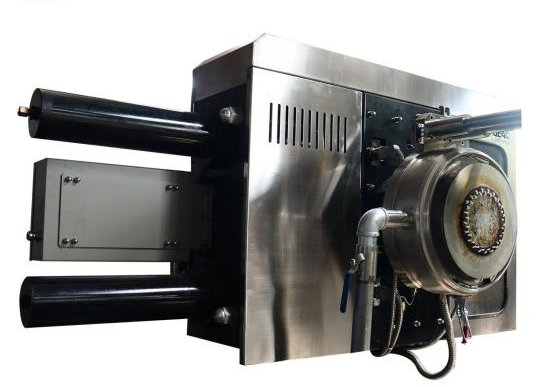

| Pellet type | Hot die-cutting type (water-ring cutting) |

| Cooling method | Water cooling |

| Voltage | Customization (for example: 480V 60Hz in the United States, 440V/220V 60Hz in Mexico, 380V 60Hz in Saudi Arabia, 415V 50Hz in Nigeria) |

| Optional accessories | Metal detector (S+S Germany), wheel set, color master batch and additive meter, centrifugal dehydrator |

| Delivery date | It takes 50~70 days to customize the machine. |

| Warranty | One year |

| After-sales service | Engineers can be dispatched to customers' overseas factories to assist in machine installation |