china plastic recycling granulator machine

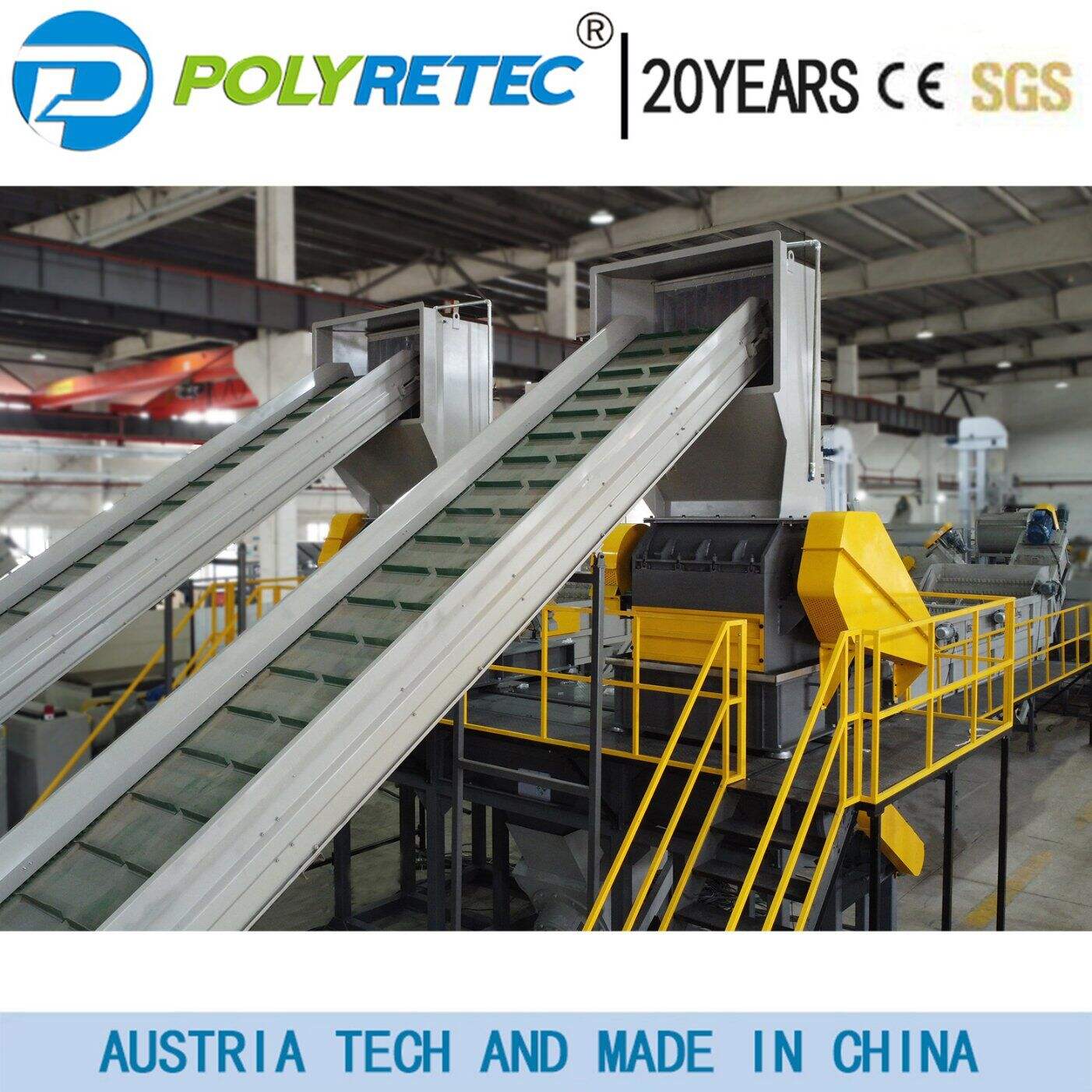

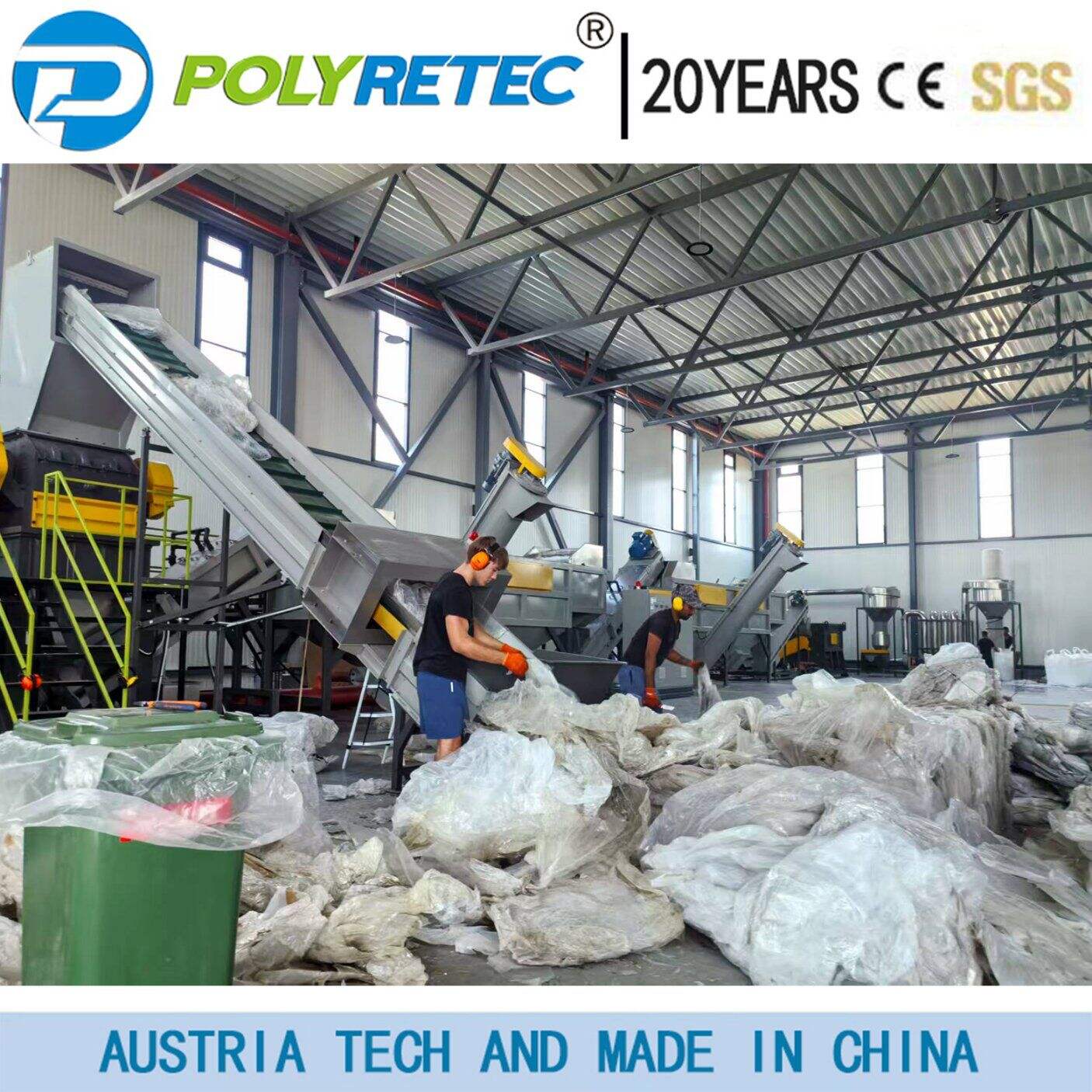

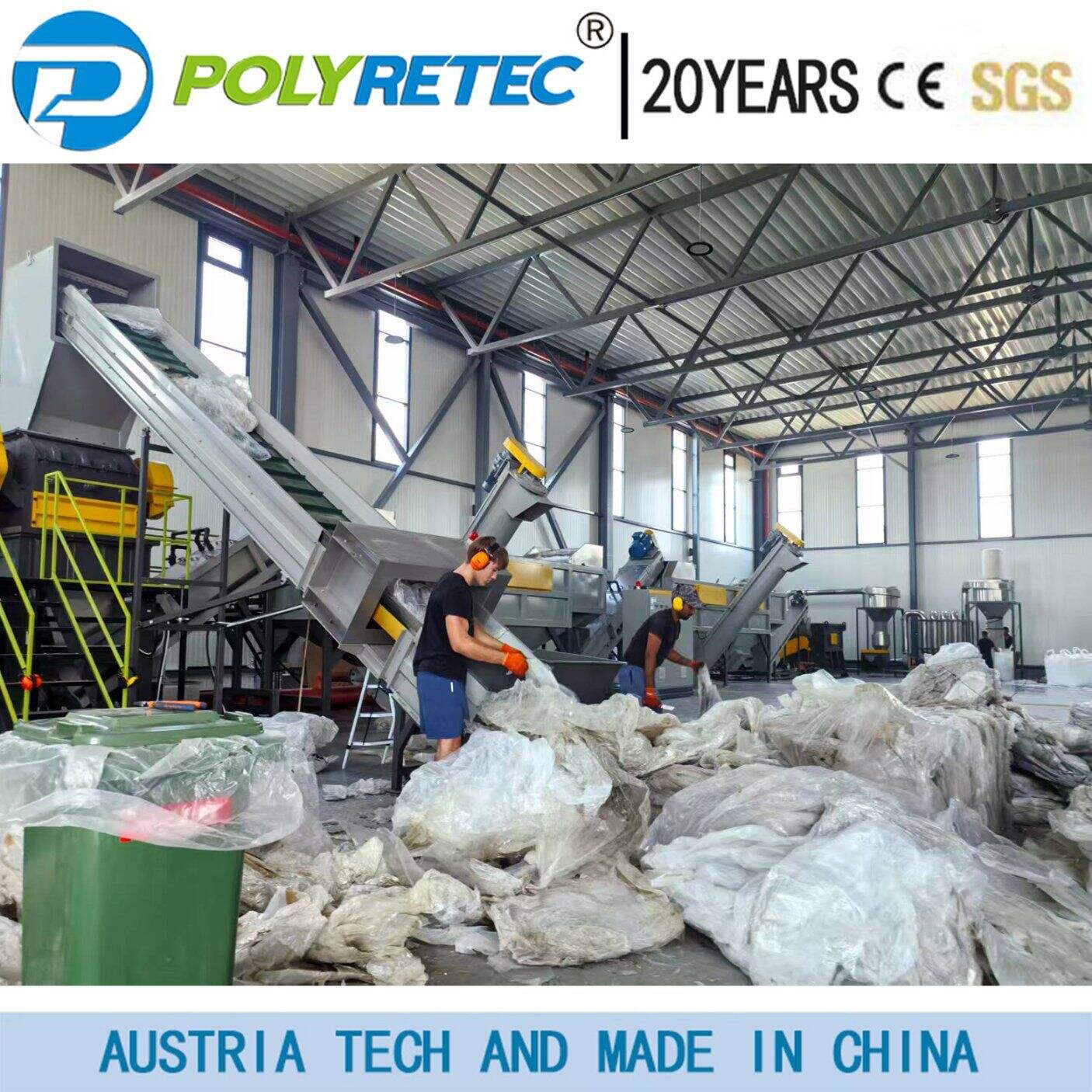

The China plastic recycling granulator machine represents a cutting-edge solution in the plastic recycling industry, engineered to efficiently process various plastic materials into high-quality granules. This advanced machinery combines robust construction with precision engineering to deliver consistent output quality. The machine features a powerful motor system that drives hardened steel blades, capable of processing up to 500kg per hour depending on the model specifications. Its innovative design includes an automatic feeding system, precise temperature control mechanisms, and an intelligent control panel for seamless operation. The granulator incorporates multiple stages of processing, including crushing, heating, extruding, and cooling, all integrated into a single efficient unit. Safety features include emergency stop mechanisms, overload protection, and noise reduction technology, ensuring operator safety and workplace compliance. The machine's versatility allows it to handle various plastic types including PE, PP, PS, ABS, and PVC, making it suitable for diverse recycling applications. Advanced screening systems ensure uniform granule size, while the cooling system maintains optimal temperature throughout the process for consistent output quality.