plastic recycling machine price in china

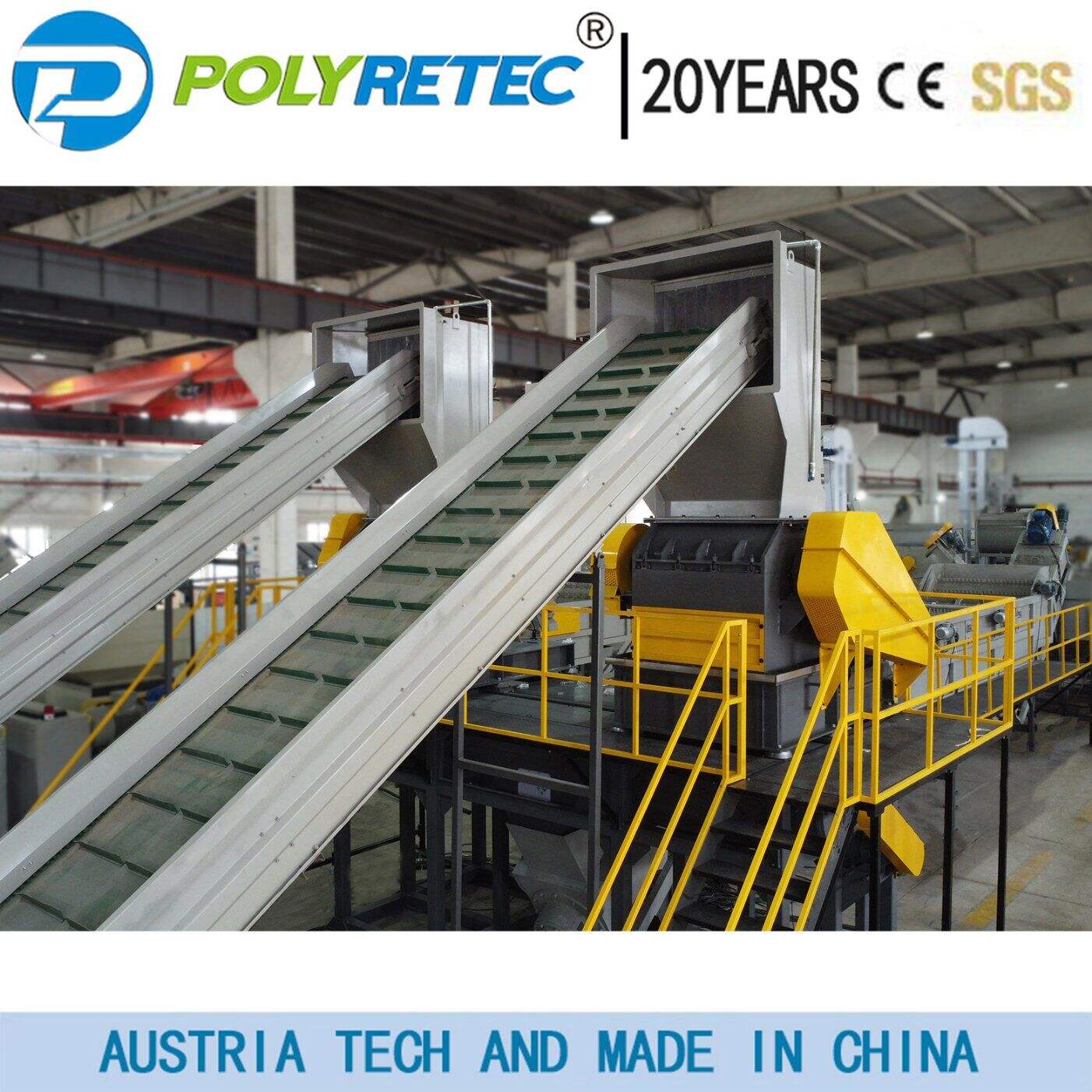

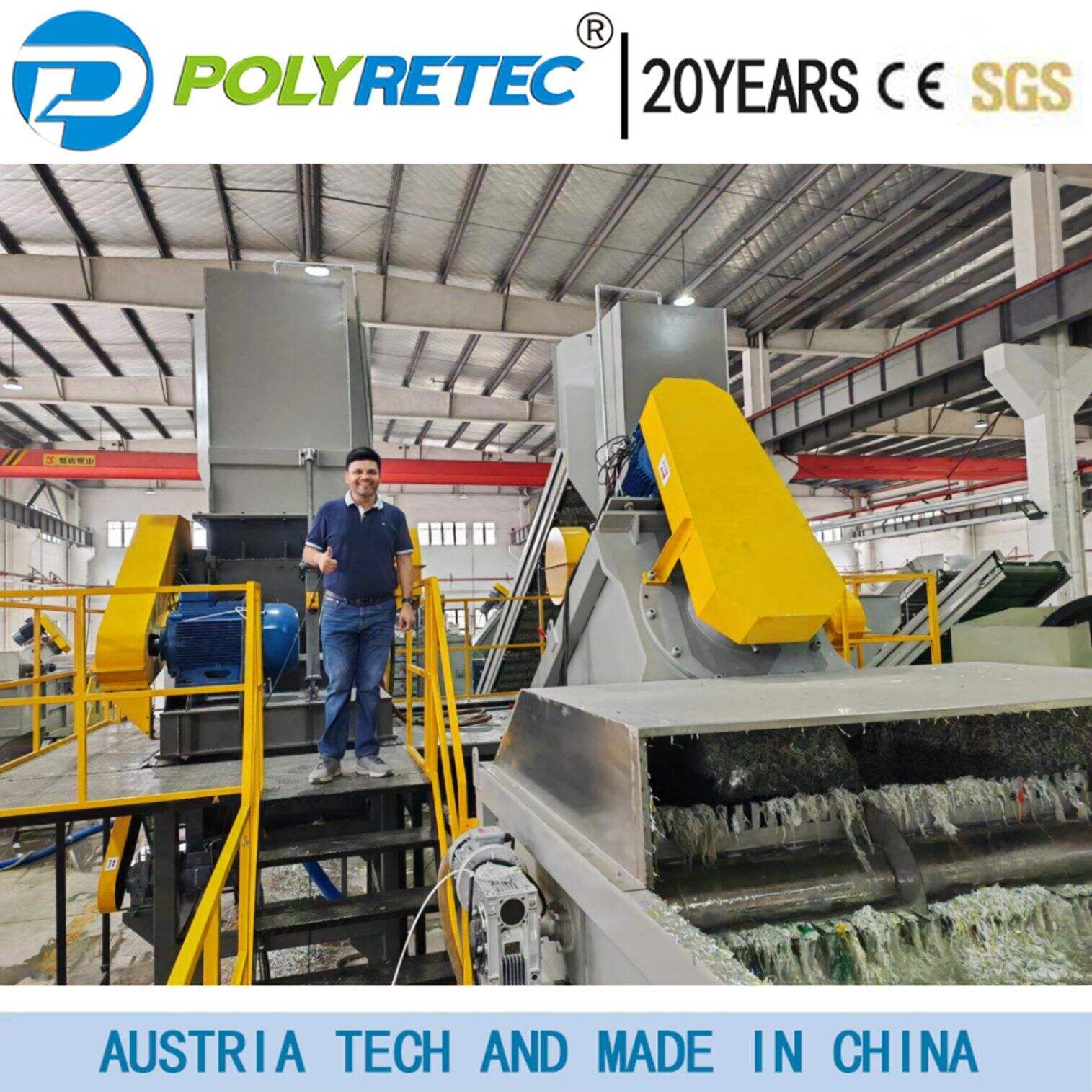

The plastic recycling machine price in China represents a significant investment opportunity for businesses seeking cost-effective recycling solutions. These machines, ranging from $10,000 to $100,000 depending on capacity and specifications, offer comprehensive plastic processing capabilities. Modern Chinese recycling machines incorporate advanced sorting mechanisms, washing systems, and pelletizing units, capable of processing various plastic types including PET, HDPE, and PP. The machines feature automated feeding systems, precise temperature control, and intelligent monitoring systems that ensure consistent output quality. With processing capacities ranging from 200 to 2000 kg/hour, these machines accommodate different production scales. The technology includes multiple stages: sorting, crushing, washing, drying, and pelletizing, all integrated into a single production line. Chinese manufacturers have optimized these machines for energy efficiency, incorporating inverter controls and heat recovery systems that reduce operational costs. The competitive pricing, combined with reliable performance and modern technology, makes Chinese plastic recycling machines an attractive option for both starting recycling businesses and expanding existing operations.