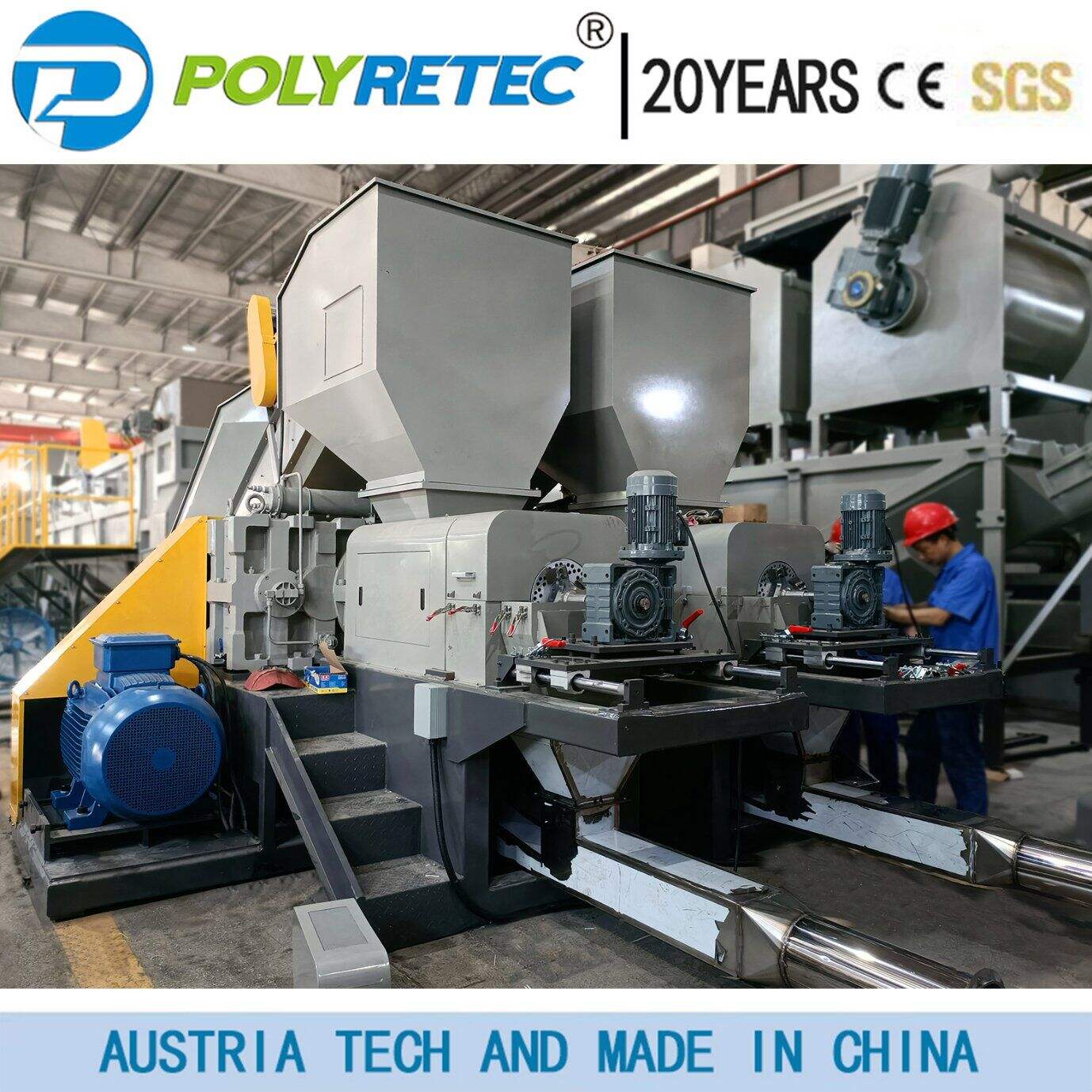

china machines to recycle plastic

China machines to recycle plastic represent cutting-edge solutions in the waste management industry, offering comprehensive systems for processing various types of plastic waste. These machines incorporate advanced sorting mechanisms, washing units, crushing systems, and pelletizing equipment to transform plastic waste into reusable materials. The technological features include automated sorting systems using infrared sensors and AI-powered recognition technology to identify different plastic types. The crushing units utilize hardened steel blades and precise cutting mechanisms to reduce plastics to uniform sizes, while the washing systems employ multiple stages of cleaning with eco-friendly detergents to remove contaminants. The pelletizing process involves sophisticated heating and extrusion systems that ensure consistent quality of the final product. These machines can process multiple types of plastics including PET, HDPE, LDPE, and PP, with processing capacities ranging from 500 to 5000 kg per hour. The systems are designed with modular components allowing for customization based on specific requirements and scale of operations.