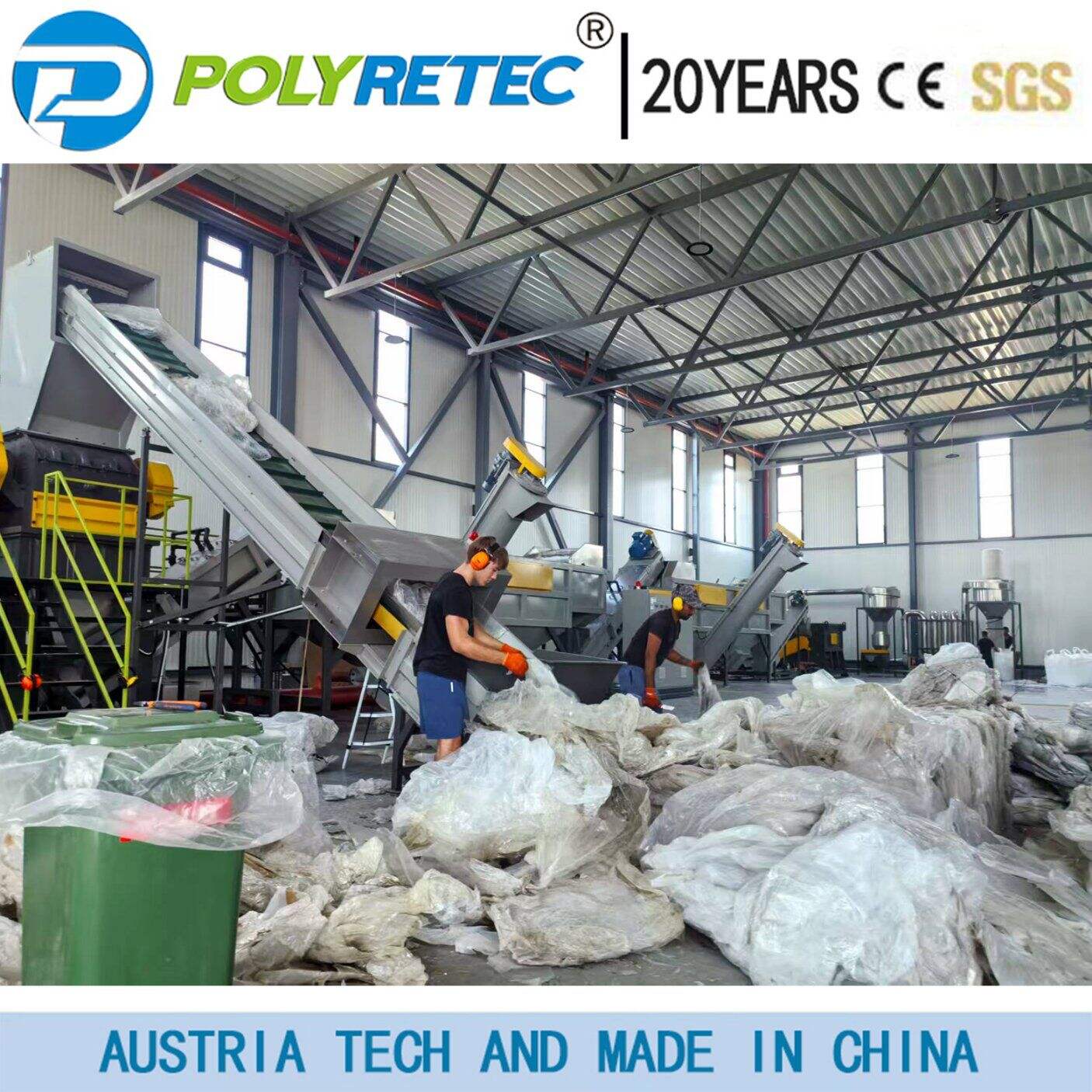

china plastic bottle recycling machine

The China plastic bottle recycling machine represents a cutting-edge solution for efficient waste management and environmental sustainability. This advanced system processes used plastic bottles through multiple stages, including sorting, crushing, washing, and pelletizing, transforming waste materials into valuable recycled products. The machine incorporates automated sorting technology that efficiently separates different types of plastics, ensuring optimal processing quality. Its high-capacity crushing system can handle various bottle sizes and thicknesses, while the advanced washing system removes contaminants and labels effectively. The pelletizing stage converts processed material into high-quality plastic pellets suitable for manufacturing new products. With processing capabilities ranging from 300 to 3000 kg per hour, these machines are adaptable to different operational scales. The system features precise temperature control mechanisms and energy-efficient components that optimize resource usage while maintaining consistent output quality. Modern safety features, including emergency stop systems and overload protection, ensure operator safety and equipment longevity. The machine's modular design allows for easy maintenance and future upgrades, making it a versatile solution for recycling facilities, waste management companies, and manufacturing plants.