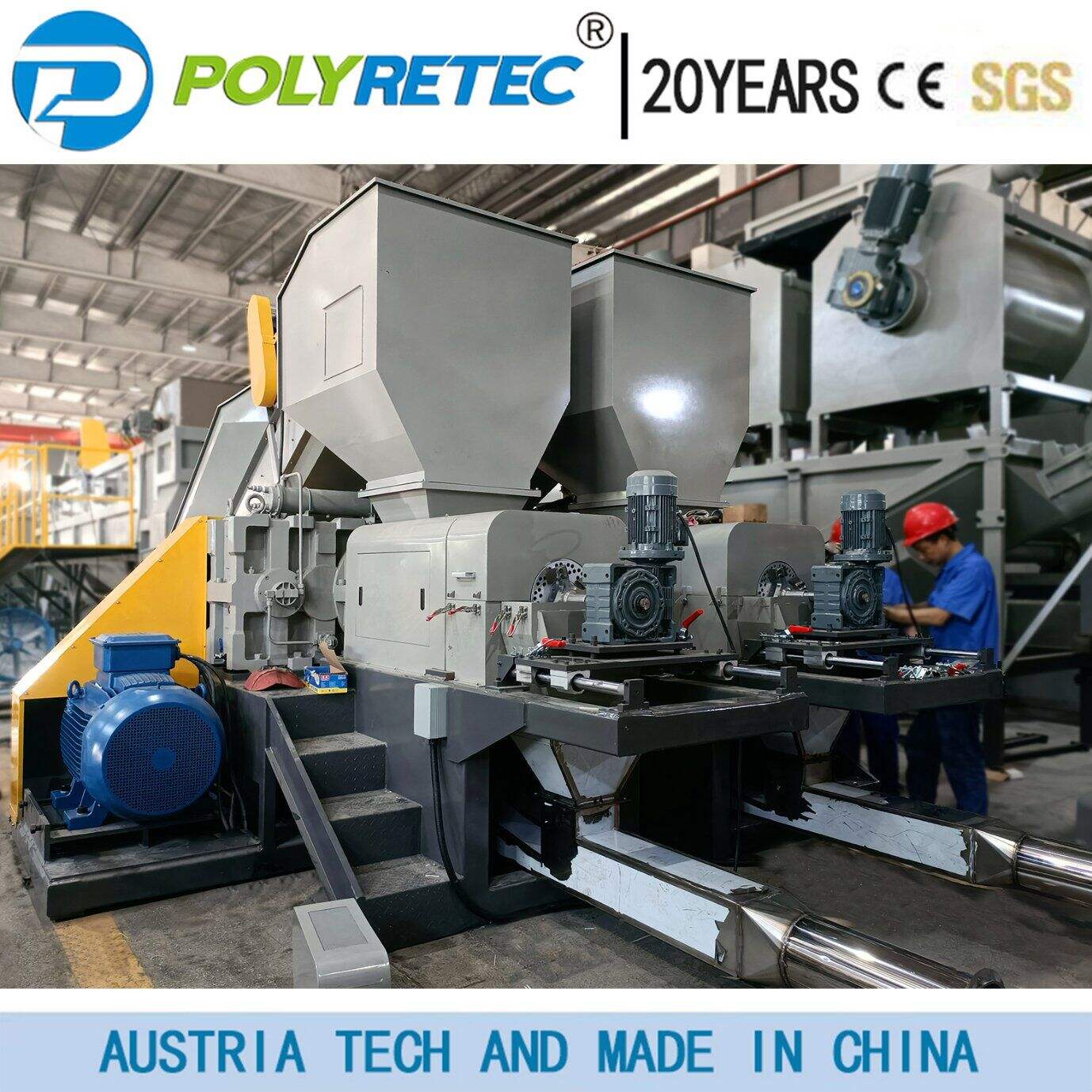

china recycling granulator machine

The China recycling granulator machine represents a cutting-edge solution in plastic waste processing and recycling operations. This versatile equipment efficiently transforms various plastic materials into uniform granules through a sophisticated cutting and grinding mechanism. The machine features a robust cutting chamber equipped with rotary and fixed blades, designed to process materials ranging from soft plastics to rigid industrial waste. Operating at adjustable speeds between 400-800 rpm, it ensures precise granulation while maintaining material integrity. The granulator incorporates advanced safety features including emergency stop systems and overload protection mechanisms. Its screen system allows for customizable particle sizes, typically ranging from 4mm to 12mm, meeting diverse industry requirements. The machine's design emphasizes energy efficiency through its optimized cutting geometry and advanced motor technology, reducing operational costs while maintaining high throughput rates. Notable features include automatic feeding systems, integrated cooling mechanisms, and user-friendly control interfaces that enable precise operational management. The granulator finds extensive applications across various industries, including packaging material recycling, plastic product manufacturing, and industrial waste management sectors.