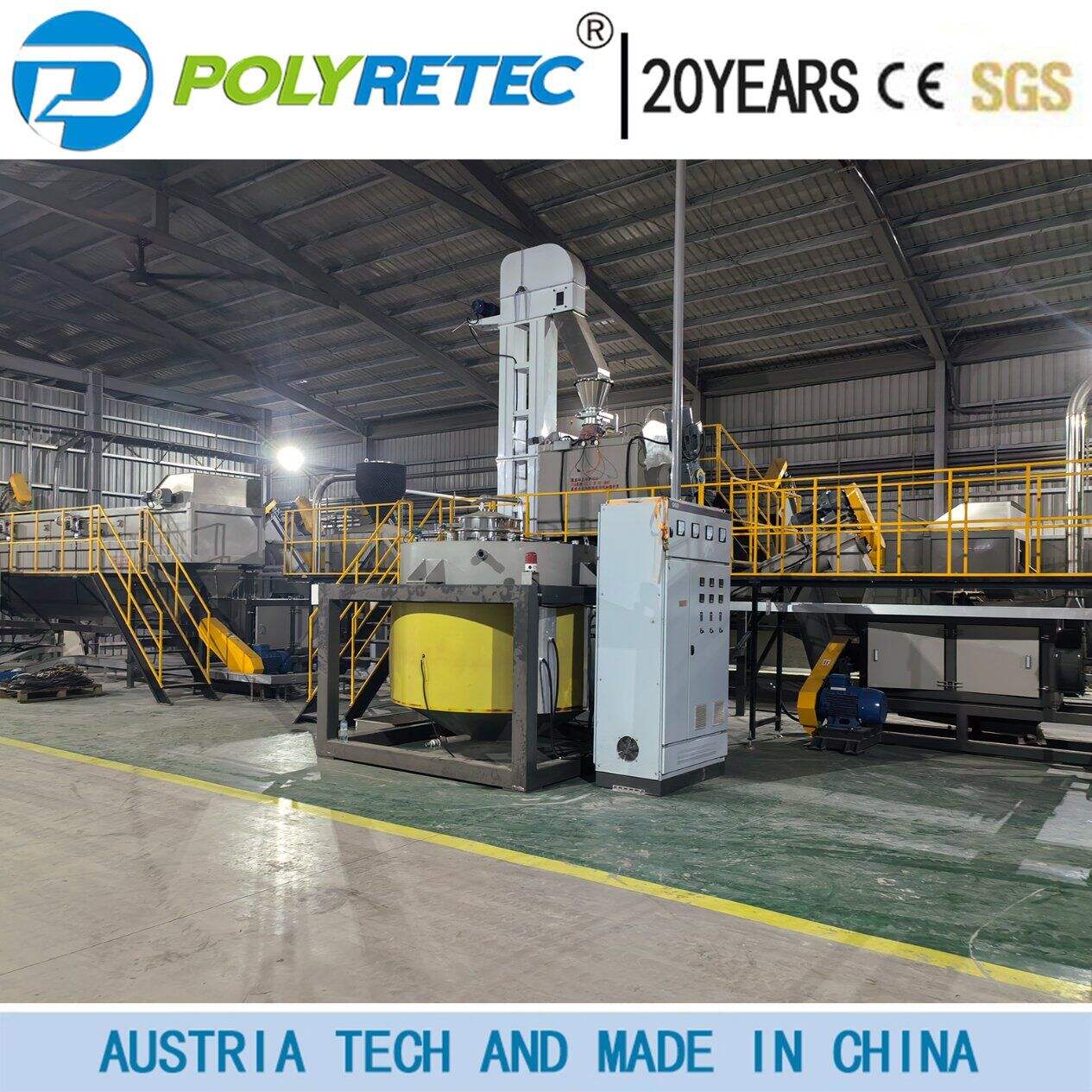

plastic recycling machine made in china

The plastic recycling machine made in China represents a significant advancement in environmental technology, offering a comprehensive solution for processing various types of plastic waste. This innovative equipment combines robust engineering with cost-effective manufacturing, featuring a multi-stage processing system that includes sorting, crushing, washing, drying, and pelletizing capabilities. The machine utilizes advanced shredding technology with hardened steel blades that efficiently reduce plastic materials to uniform sizes, while its integrated washing system removes contaminants and ensures high-quality output. The automated control system maintains optimal operating parameters, allowing for consistent production quality and minimal operator intervention. With processing capacities ranging from 500 to 3000 kg per hour, these machines can handle multiple plastic types including PET, HDPE, LDPE, and PP. The system's energy-efficient design incorporates heat recovery mechanisms and water recycling features, significantly reducing operational costs while maintaining environmental sustainability. These machines are equipped with safety features such as emergency stop systems and overload protection, ensuring safe operation in industrial settings. The modular design allows for easy maintenance and future upgrades, while the compact footprint maximizes space efficiency in recycling facilities.