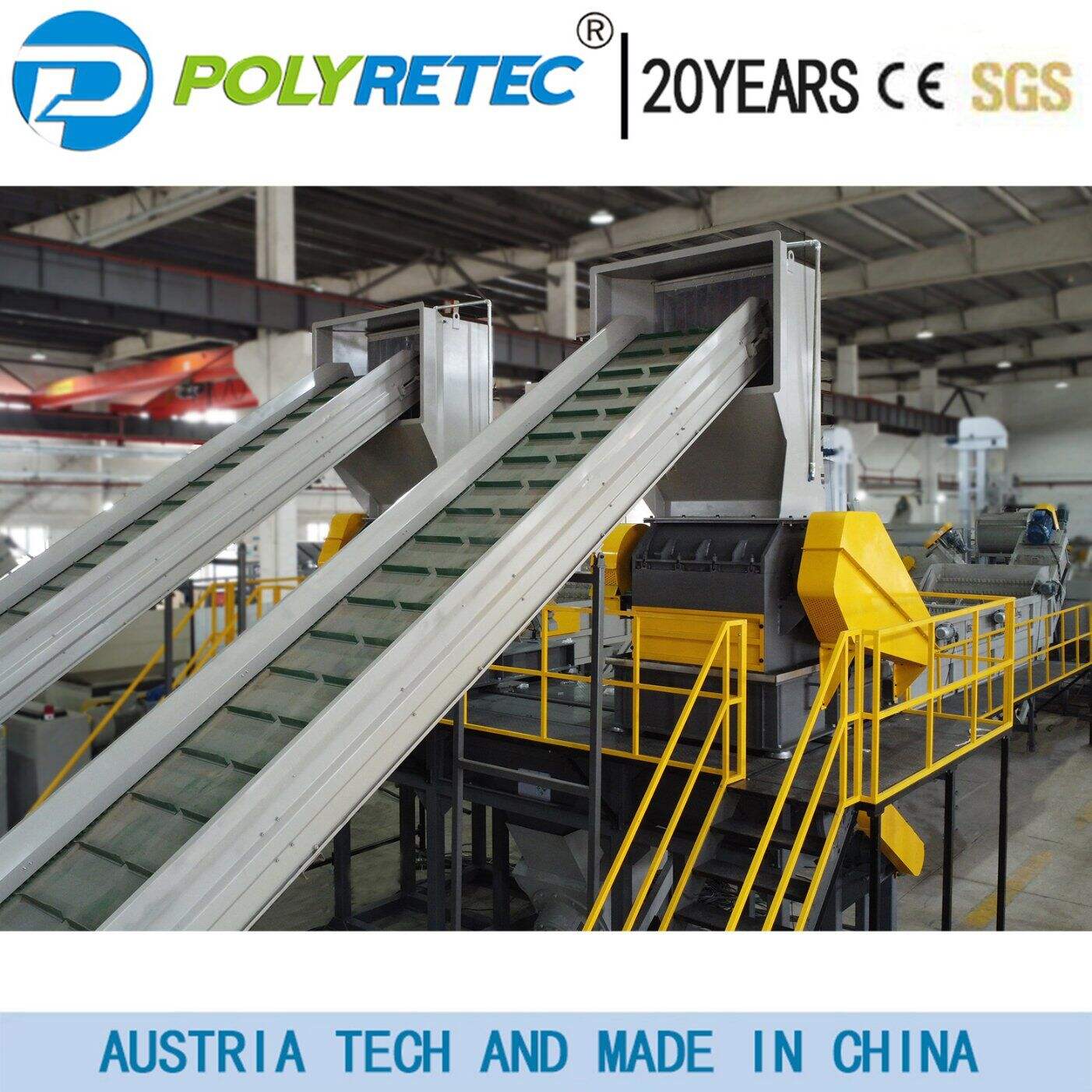

china plastic recycling granulator

The China plastic recycling granulator represents a cutting-edge solution in waste plastic processing technology. This sophisticated machine efficiently transforms various plastic waste materials into high-quality recycled granules through a comprehensive process of crushing, heating, extruding, and pelletizing. The granulator features a robust design with a hardened steel cutting chamber, precision-engineered blades, and an advanced control system that ensures consistent output quality. Its versatile processing capability allows it to handle multiple types of plastics, including PE, PP, PS, and ABS materials, making it an invaluable asset for recycling facilities. The machine incorporates an intelligent temperature control system that maintains optimal processing conditions throughout the granulation process, while its high-torque screw design ensures efficient material conveyance and mixing. With processing capacities ranging from 100 to 500 kg per hour, depending on the model, these granulators can meet various production requirements. The system also includes advanced safety features such as emergency stop mechanisms and overload protection, ensuring safe and reliable operation.