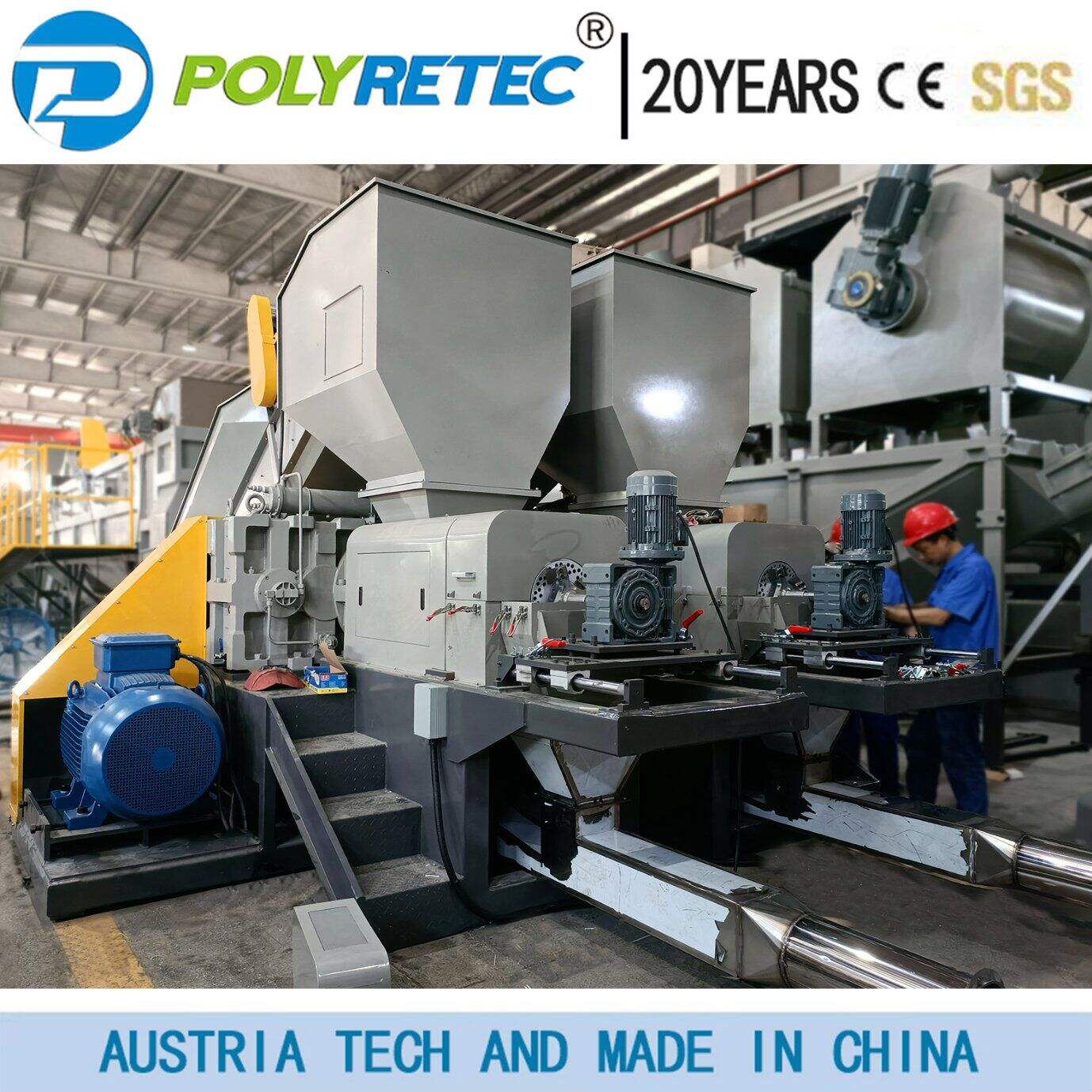

china plastic recycling machine

The China plastic recycling machine represents a cutting-edge solution for sustainable waste management, designed to transform various plastic materials into reusable resources. This advanced system incorporates multiple processing stages, including sorting, crushing, washing, drying, and pelletizing, all integrated into a single efficient unit. The machine can handle diverse plastic types, from PET bottles to industrial plastic waste, processing them into high-quality recycled pellets suitable for manufacturing new products. Its automated control system ensures precise temperature regulation and material flow management, maximizing output quality while minimizing energy consumption. The machine's robust construction, featuring wear-resistant components and corrosion-protected surfaces, ensures reliable long-term operation in demanding industrial environments. With processing capabilities ranging from 300 to 1000 kg per hour, depending on the model, these machines offer scalable solutions for different operational needs. The system's advanced filtration technology removes contaminants effectively, producing clean, consistent output material that meets international quality standards.