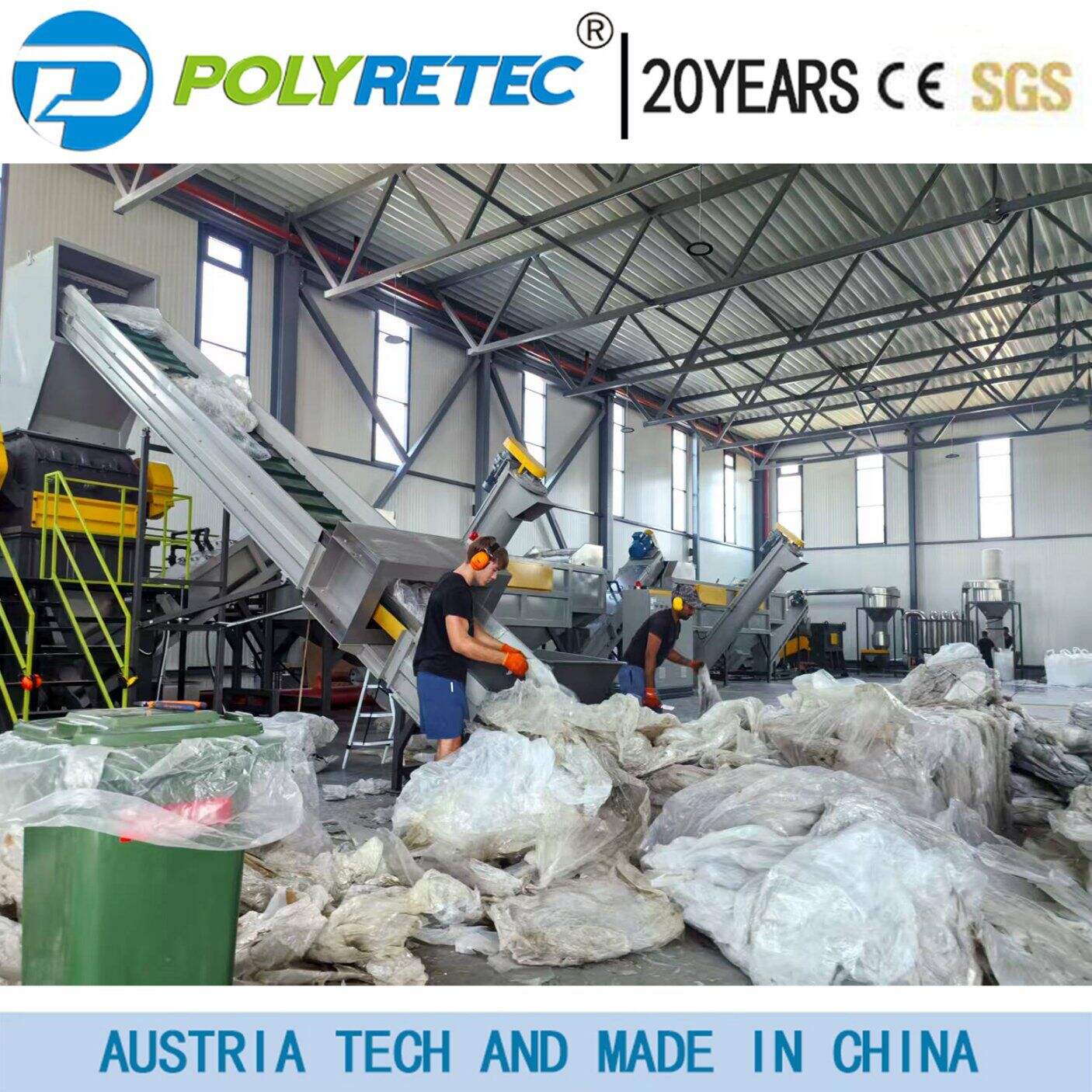

china pet bottle recycling machine

The China PET bottle recycling machine represents a cutting-edge solution in waste management technology, designed to process post-consumer PET bottles into valuable recycled materials. This advanced system incorporates multiple stages of processing, including sorting, crushing, washing, and pelletizing, all integrated into a single efficient unit. The machine can handle various sizes and types of PET bottles, processing them through an automated system that ensures consistent output quality. With processing capabilities ranging from 300 to 3000 kg per hour, these machines utilize advanced sensor technology for contaminant detection and removal, ensuring the final product meets international quality standards. The system features precision-engineered crushing mechanisms that reduce bottles to optimal flake sizes, followed by a thorough washing process that removes labels, caps, and other contaminants. The integration of hot washing technology ensures deep cleaning of the PET flakes, while the advanced drying system minimizes moisture content in the final product. This machinery incorporates energy-efficient motors and intelligent control systems that optimize power consumption while maintaining high productivity levels. The entire process is monitored through a user-friendly interface that provides real-time data on operation parameters and system performance.