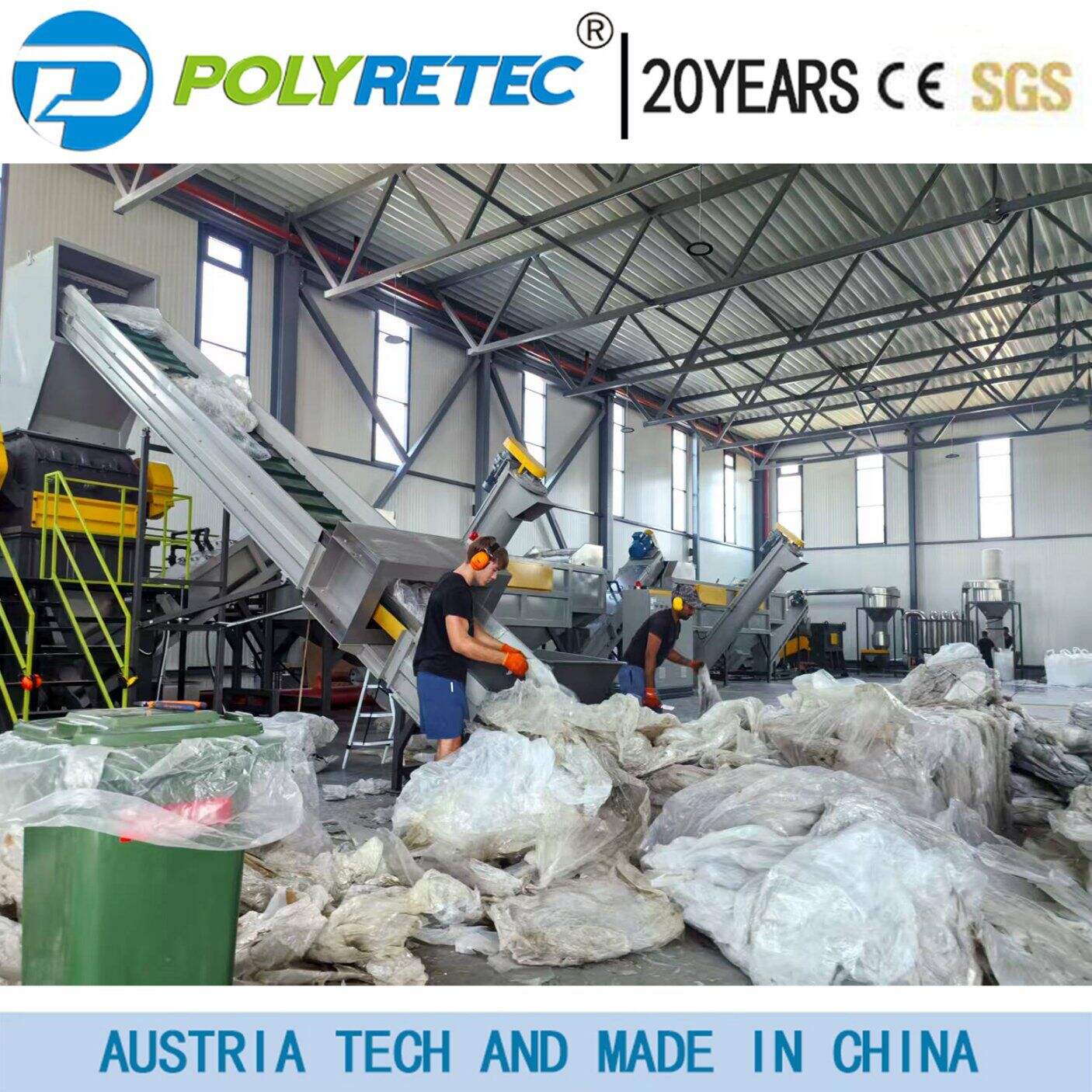

china pelletizing machine for plastic recycling

The China pelletizing machine for plastic recycling represents a state-of-the-art solution for transforming plastic waste into valuable reusable materials. This advanced equipment utilizes a comprehensive process that begins with the sorting and cleaning of plastic waste, followed by precise grinding and melting phases. The machine incorporates a sophisticated extrusion system that processes the melted plastic through specialized die holes, creating uniform pellets that meet industry standards. The system features intelligent temperature control mechanisms across multiple heating zones, ensuring optimal material properties throughout the process. Key technological features include automated feeding systems, precise screw designs for consistent material flow, and advanced cutting mechanisms that produce uniform pellet sizes. The machine can process various plastic types, including PE, PP, PS, ABS, and PVC, making it versatile for different recycling applications. With processing capacities ranging from 100 to 1000 kg per hour, these machines are suitable for both small-scale recycling operations and large industrial facilities. The integration of PLC control systems enables precise operation parameters and monitoring, while the water-cooling system ensures proper pellet formation and maintains product quality.