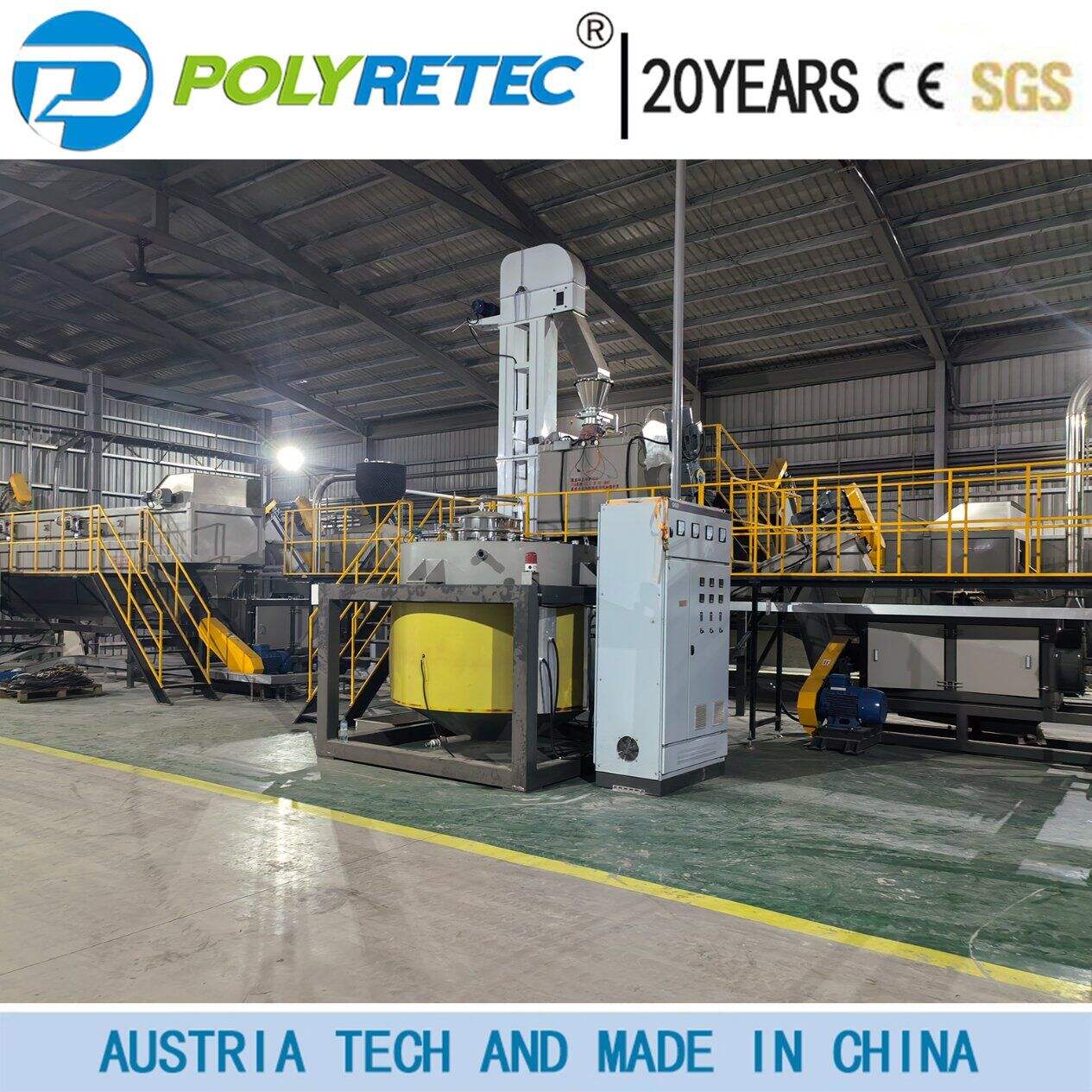

china machine for plastic recycling

The China machine for plastic recycling represents a cutting-edge solution in waste management technology, designed to transform plastic waste into valuable recycled materials. This advanced system incorporates multiple processing stages, including sorting, crushing, washing, and pelletizing, all integrated into a single efficient unit. The machine utilizes sophisticated sensors and automated sorting mechanisms to separate different types of plastics, ensuring optimal processing quality. Its robust crushing system can handle various plastic materials, from PET bottles to industrial waste, reducing them to uniform sizes for efficient processing. The washing system employs high-pressure water jets and specialized cleaning agents to remove contaminants, labels, and adhesives, while the innovative drying system ensures moisture content meets industry standards. The pelletizing stage features precision temperature control and advanced screw design for consistent output quality. With processing capacities ranging from 500 to 3000 kg per hour, these machines are adaptable to different operational scales. The system's modular design allows for easy maintenance and future upgrades, while its advanced control panel provides real-time monitoring and adjustment capabilities for all processing parameters.