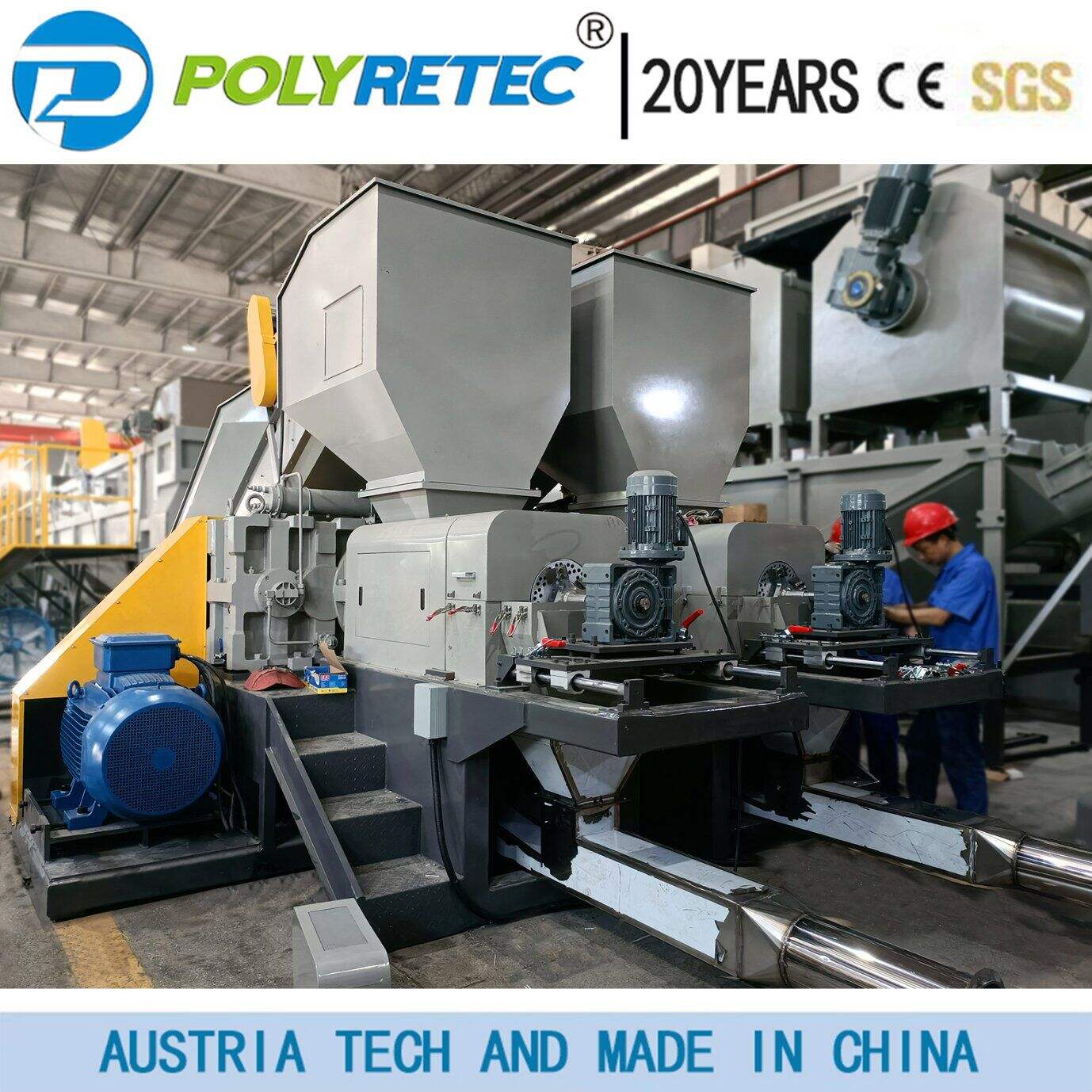

polythene recycling machine

The polythene recycling machine represents a cutting-edge solution for transforming waste plastic materials into valuable recycled products. This sophisticated equipment operates through a streamlined process that begins with the shredding of polythene materials into smaller, manageable pieces. The machine incorporates advanced grinding technology that reduces plastic waste to uniform sizes, ensuring consistent quality in the final output. A high-efficiency washing system then removes contaminants and impurities, while the drying unit prepares the material for the next phase. The heart of the machine lies in its extrusion system, where the processed plastic is melted and homogenized at precisely controlled temperatures. The molten material passes through a filtration system that removes any remaining impurities before being pelletized into uniform, high-quality recycled plastic granules. Modern polythene recycling machines are equipped with smart control systems that monitor and adjust processing parameters in real-time, ensuring optimal performance and product quality. These machines can process various types of polythene materials, including LDPE, HDPE, and LLDPE, making them versatile solutions for recycling facilities, manufacturing plants, and waste management operations. The automation features reduce manual intervention, leading to increased safety and operational efficiency.