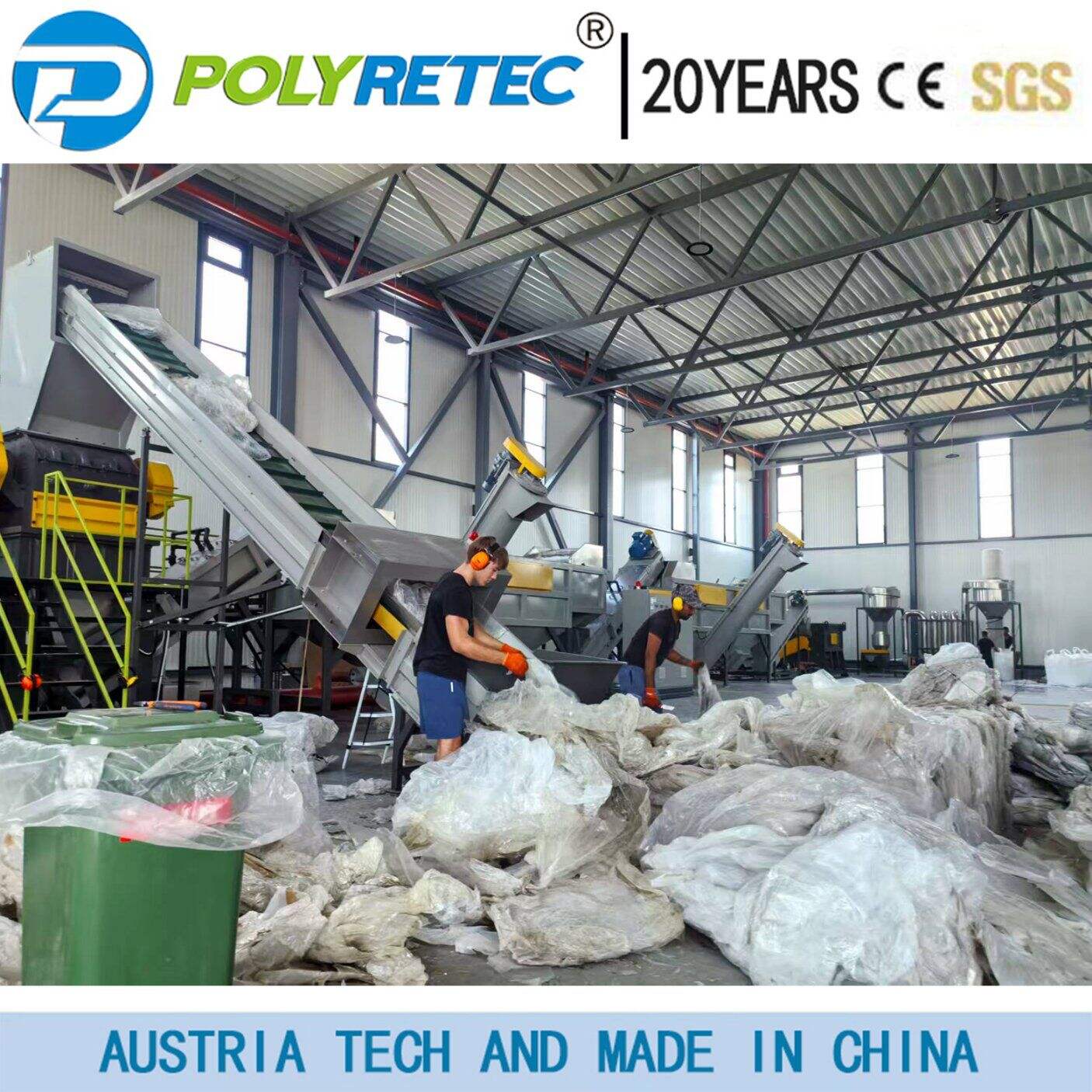

soft plastic recycling machine

The soft plastic recycling machine represents a cutting-edge solution for transforming plastic waste into valuable resources. This advanced system efficiently processes various soft plastic materials, including LDPE, HDPE, and PP, through a sophisticated multi-stage process. The machine begins with a powerful shredding mechanism that reduces plastic waste to uniform sizes, followed by a washing system that removes contaminants and ensures material purity. The innovative heating and extrusion system then melts the cleaned plastic particles at precisely controlled temperatures, while the granulation unit forms consistent, high-quality pellets suitable for manufacturing new products. With processing capabilities ranging from 100 to 500 kg per hour, the machine incorporates smart monitoring systems that maintain optimal operational parameters throughout the recycling process. Advanced safety features, including emergency shutdown systems and temperature controls, ensure reliable operation while protecting operators. The machine's modular design allows for easy maintenance and future upgrades, making it a sustainable investment for businesses committed to environmental responsibility.