plastic recycling machinery price

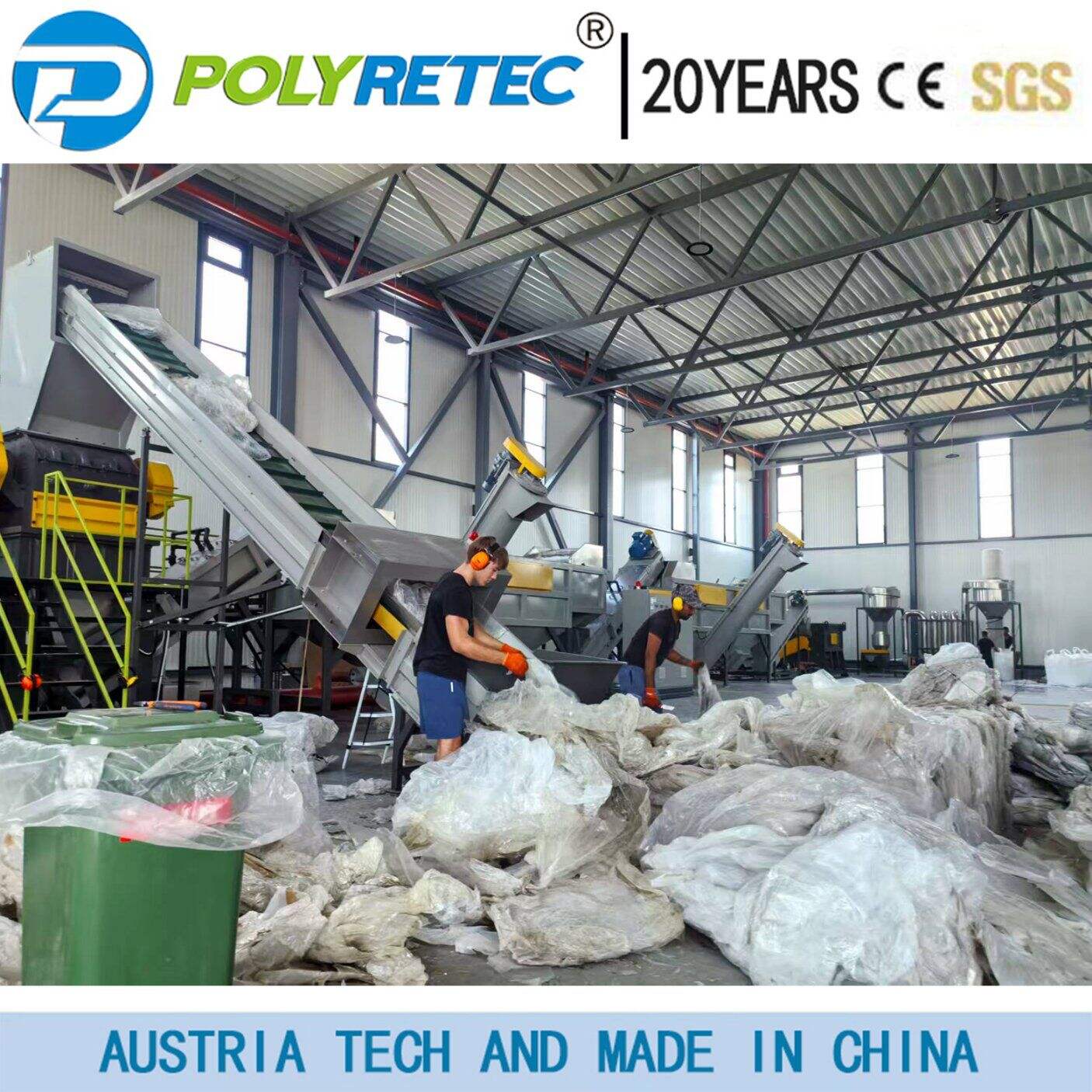

The plastic recycling machinery price represents a crucial investment consideration for businesses entering the recycling industry. Modern plastic recycling machines incorporate advanced technologies for efficient processing, including sorting mechanisms, washing systems, and pelletizing units. These machines typically range from $10,000 to $200,000, depending on capacity, automation level, and processing capabilities. The machinery's price reflects its ability to handle various plastic types, from PET to HDPE, with processing capacities ranging from 100 to 3000 kg per hour. Key factors influencing the price include automation features, energy efficiency systems, and quality control mechanisms. The machinery typically includes pre-washing stations, hot washing units, high-speed centrifugal drying systems, and advanced extrusion technology. These components work together to transform plastic waste into high-quality recycled materials suitable for manufacturing. The price also accounts for essential safety features, monitoring systems, and control panels that ensure optimal operation and maintenance efficiency. Modern units often include IoT capabilities for remote monitoring and predictive maintenance, adding value to the investment.