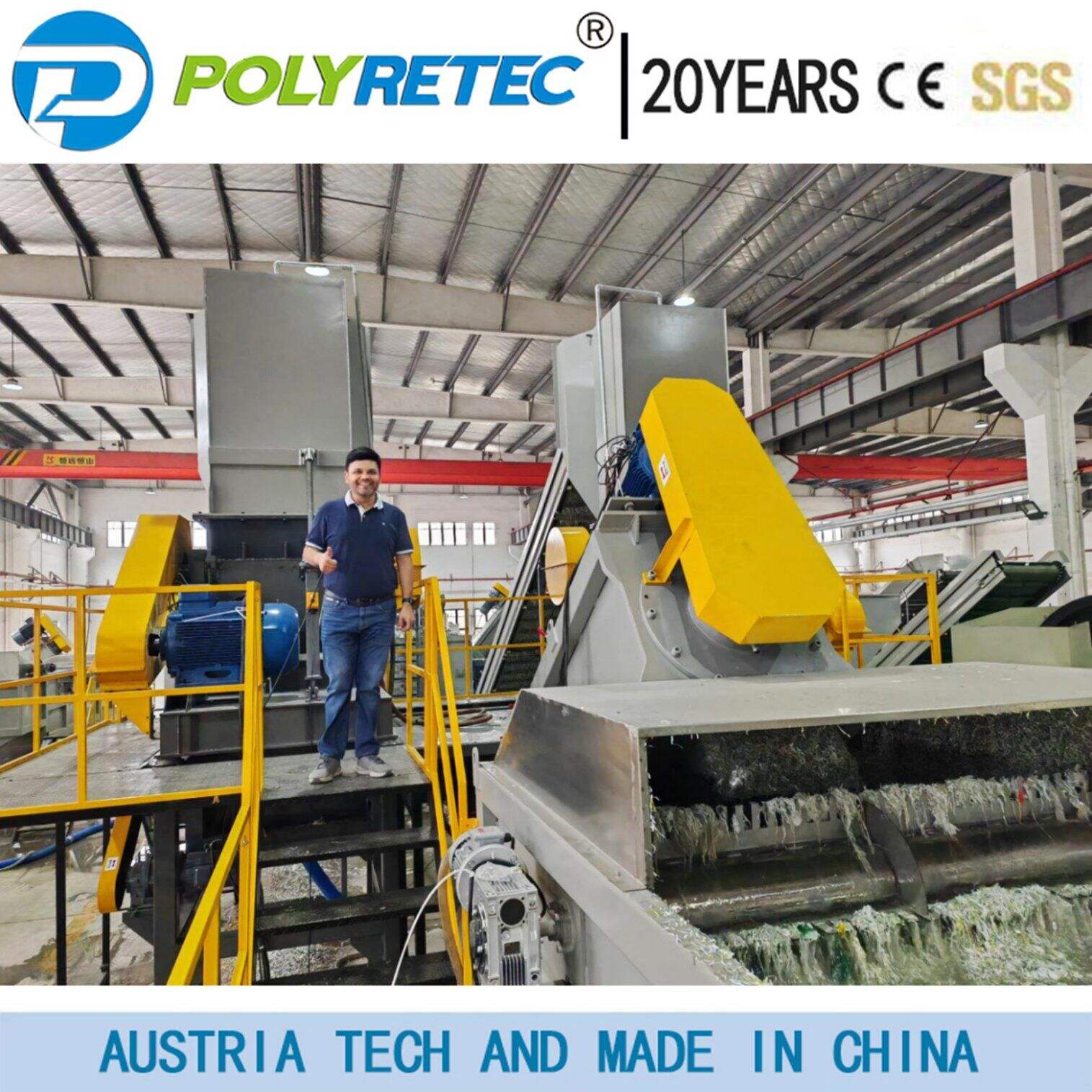

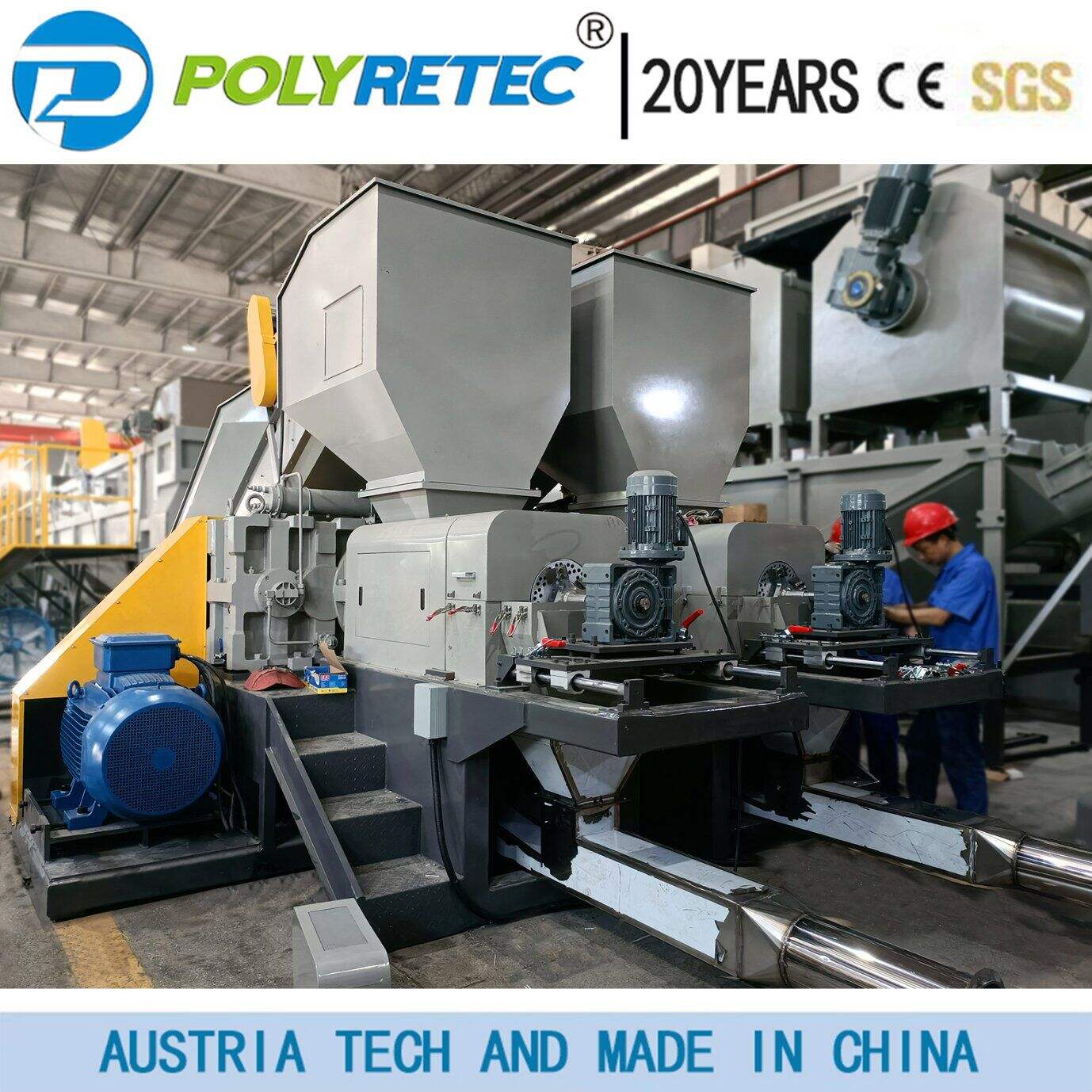

waste polythene recycling machine

The waste polythene recycling machine represents a cutting-edge solution for transforming plastic waste into valuable resources. This sophisticated equipment efficiently processes various types of waste polythene materials, including bags, films, and packaging materials, converting them into high-quality recycled plastic pellets. The machine operates through a comprehensive system that includes multiple stages: sorting, crushing, washing, drying, melting, and pelletizing. Its advanced control system ensures precise temperature regulation and material flow management, resulting in consistent output quality. The machine's robust construction features stainless steel components and wear-resistant parts, ensuring durability and long-term reliability. With processing capacities ranging from 200 to 1000 kg per hour, it accommodates both small-scale and industrial operations. The integration of energy-efficient motors and innovative heating systems minimizes operational costs while maintaining optimal performance. Additionally, the machine includes safety features such as emergency shut-off systems and overload protection, ensuring operator safety and equipment longevity. This versatile system can handle various grades of polythene waste, making it suitable for recycling facilities, manufacturing plants, and waste management centers.