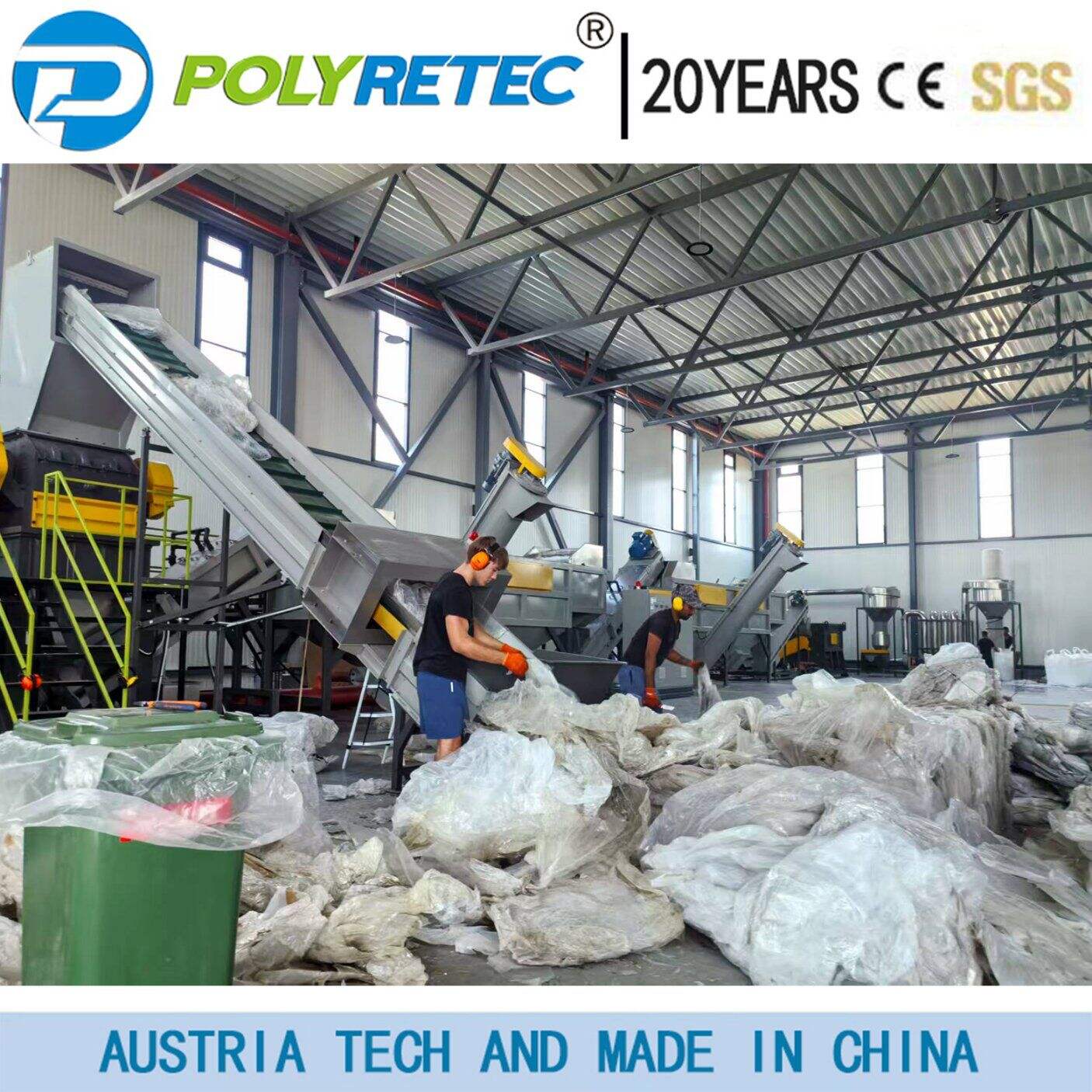

plastic shredder machine for recycling

A plastic shredder machine for recycling is an advanced industrial equipment designed to reduce various plastic materials into smaller, manageable pieces for efficient recycling processes. This robust machine incorporates hardened steel blades mounted on rotating shafts, powered by high-torque motors that can process different types of plastics, including PET, HDPE, LDPE, and PP. The machine features an innovative feeding system that safely guides materials into the cutting chamber, where the specialized blade configuration ensures consistent particle size reduction. The cutting mechanism employs both rotary and stationary blades, creating a scissor-like action that efficiently breaks down plastic materials. Advanced control systems monitor operational parameters such as motor load, temperature, and blade speed, automatically adjusting settings for optimal performance. The machine includes safety features like emergency stop buttons, overload protection, and automatic shutdown systems. Available in various sizes and capacities, these shredders can process anywhere from 100 to 3000 kg per hour, depending on the model and application requirements. The processed material can be directly used in recycling operations or further reduced in size using secondary grinding equipment.