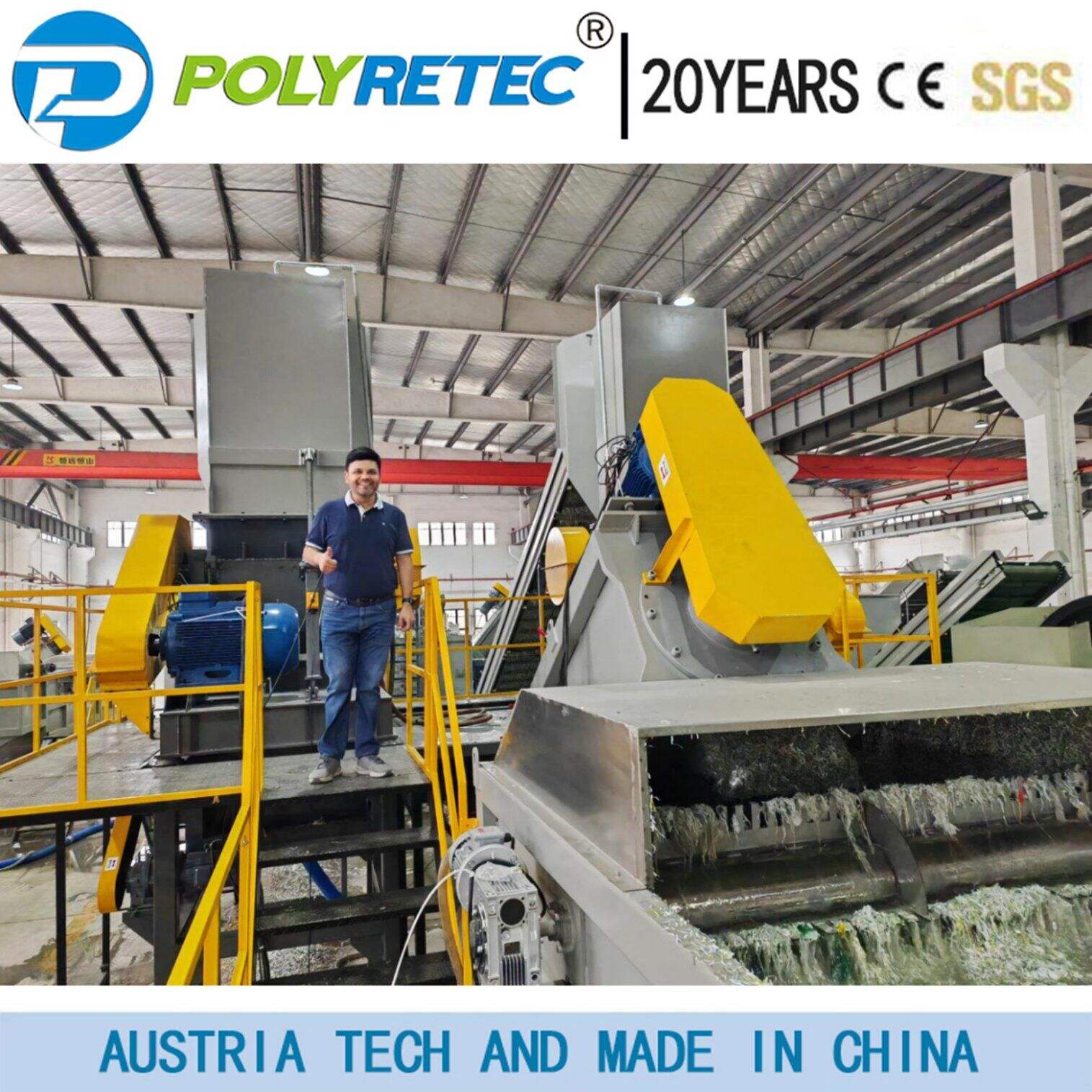

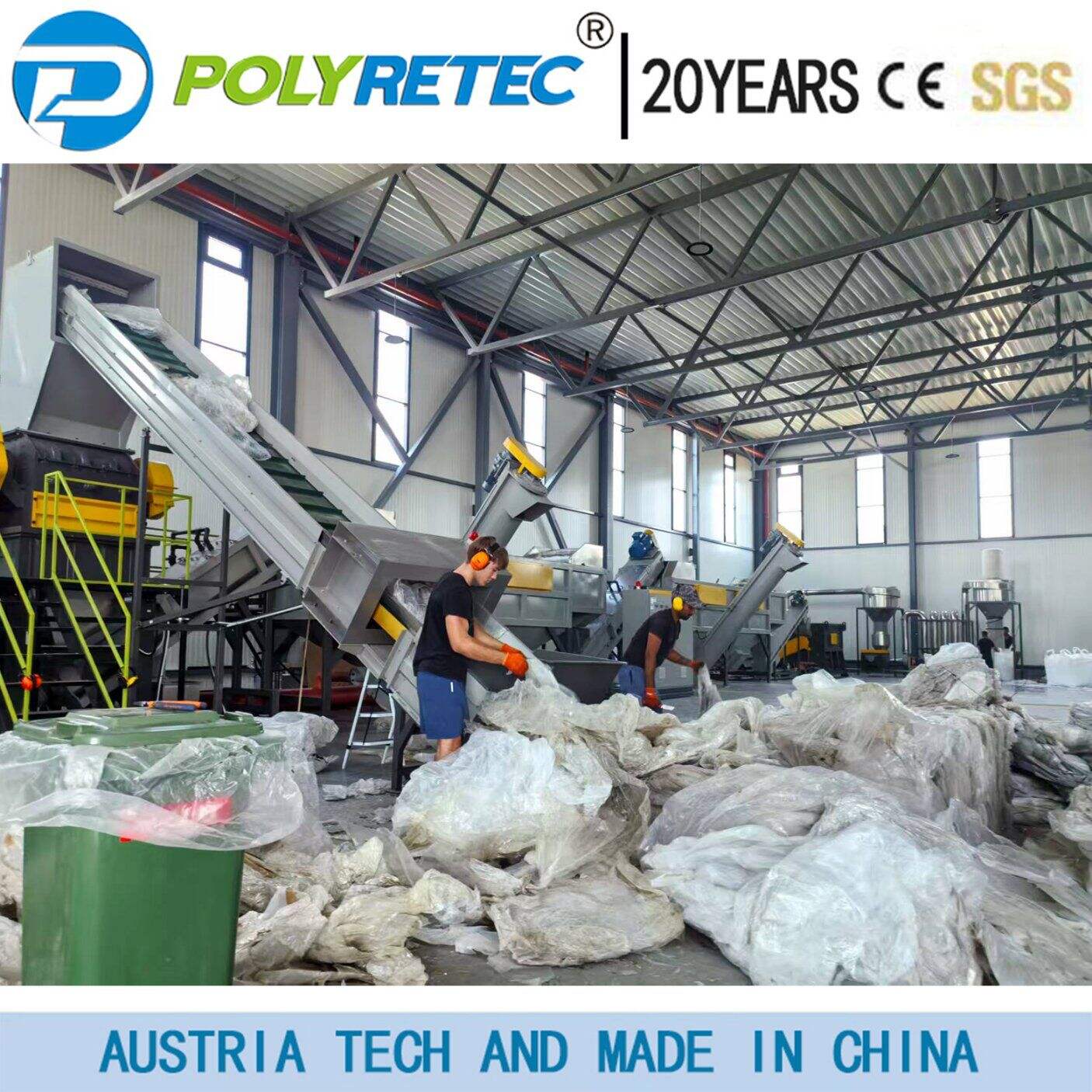

small plastic recycling machine for sale

The small plastic recycling machine for sale represents a breakthrough in sustainable waste management technology, offering a compact and efficient solution for processing various plastic materials. This versatile unit combines crushing, heating, and pelletizing functions in a space-efficient design, making it ideal for small to medium-sized operations. The machine processes multiple plastic types including PE, PP, PS, and ABS, with a processing capacity of 50-100 kg per hour. Its advanced control system ensures precise temperature regulation and consistent output quality, while the integrated cooling system maintains optimal operating conditions. The machine features a robust construction with wear-resistant components, ensuring long-term durability and reliable performance. Its user-friendly interface allows operators to easily adjust parameters such as temperature, speed, and pressure, maximizing operational efficiency. Safety features include emergency stop buttons, overload protection, and automatic shutdown mechanisms. The compact footprint makes it suitable for facilities with limited space, while its modular design facilitates maintenance and cleaning. This machine represents an economical entry point into plastic recycling, offering professional-grade capabilities in a smaller package.