plastic recycling compacting pelletizing machine

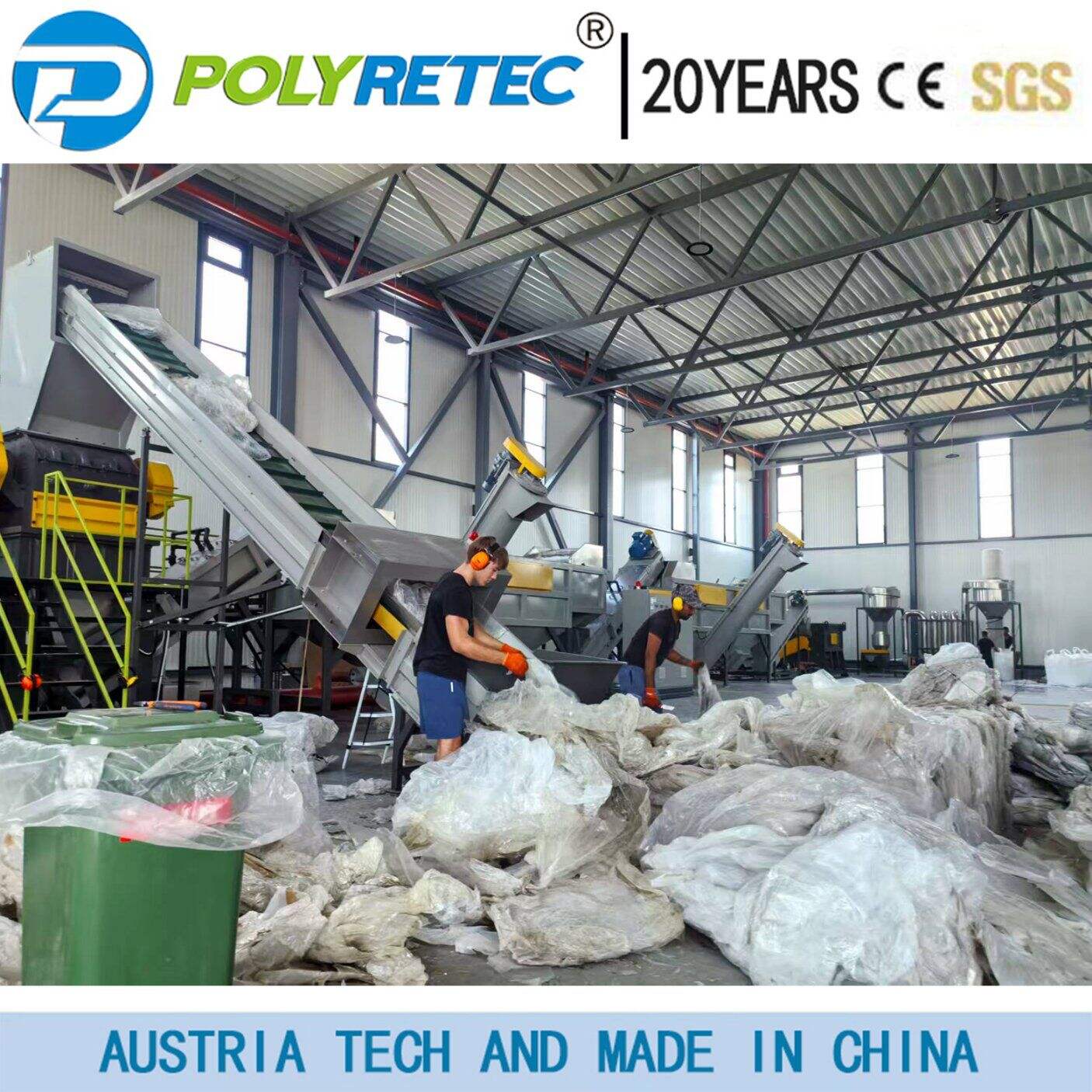

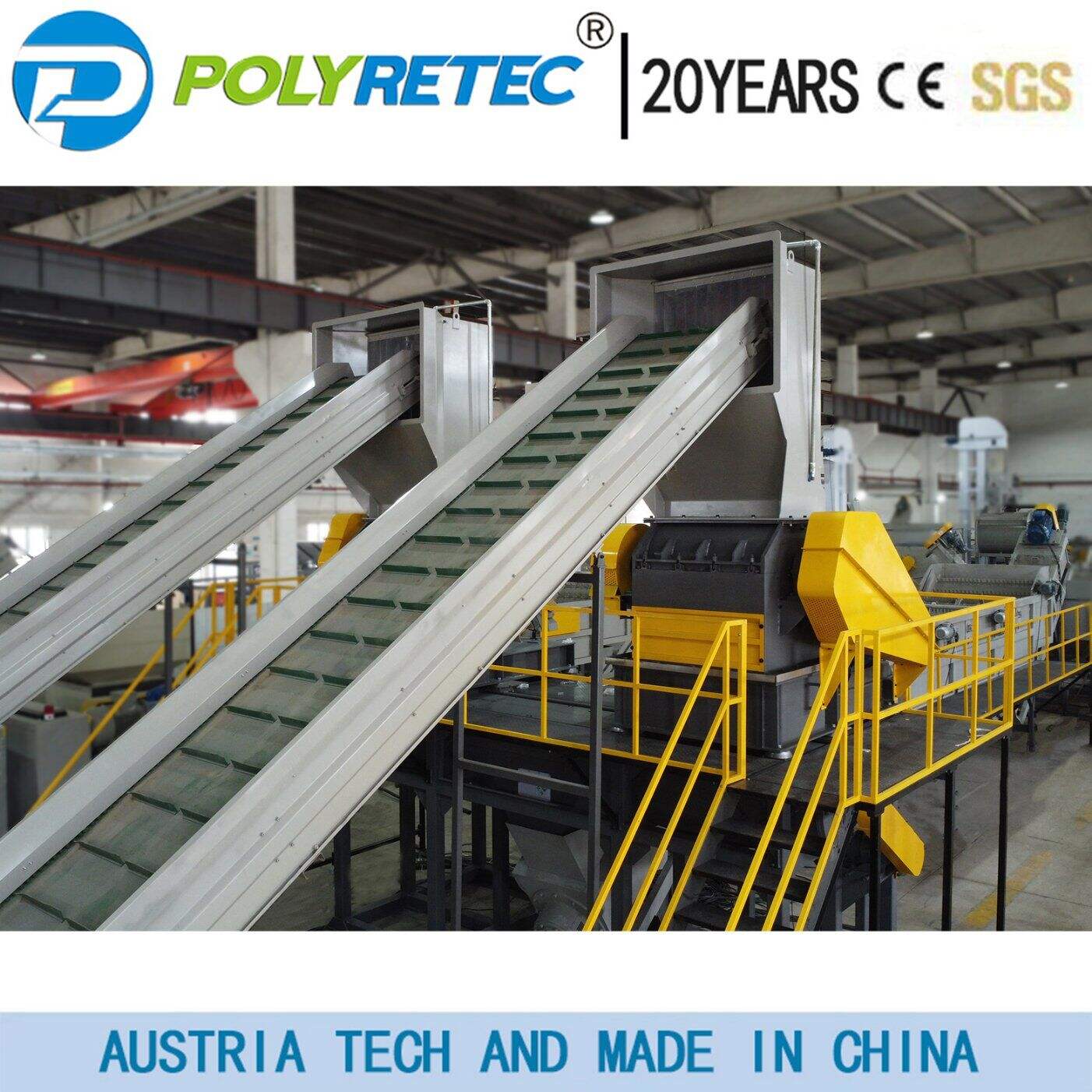

The plastic recycling compacting pelletizing machine represents a comprehensive solution for transforming plastic waste into valuable recycled materials. This advanced system combines multiple processes including sorting, crushing, washing, drying, compacting, and pelletizing into a single efficient production line. The machine efficiently processes various plastic materials such as PE, PP, PVC, and PET, converting them into uniform, high-quality pellets suitable for manufacturing new products. Its innovative design features a robust screw extruder system that ensures consistent material flow and optimal melting conditions, while the cutting mechanism produces uniform pellets with precise dimensions. The integrated control system monitors and adjusts processing parameters in real-time, maintaining product quality and operational efficiency. Advanced filtration systems remove contaminants and ensure the final pellets meet industry standards. The machine's compact design optimizes floor space while maintaining high throughput capacity, making it ideal for both small recycling operations and large-scale industrial facilities. Its versatility allows for processing different plastic grades with minimal setup changes, enabling operators to respond quickly to market demands.