waste bottle recycling machine

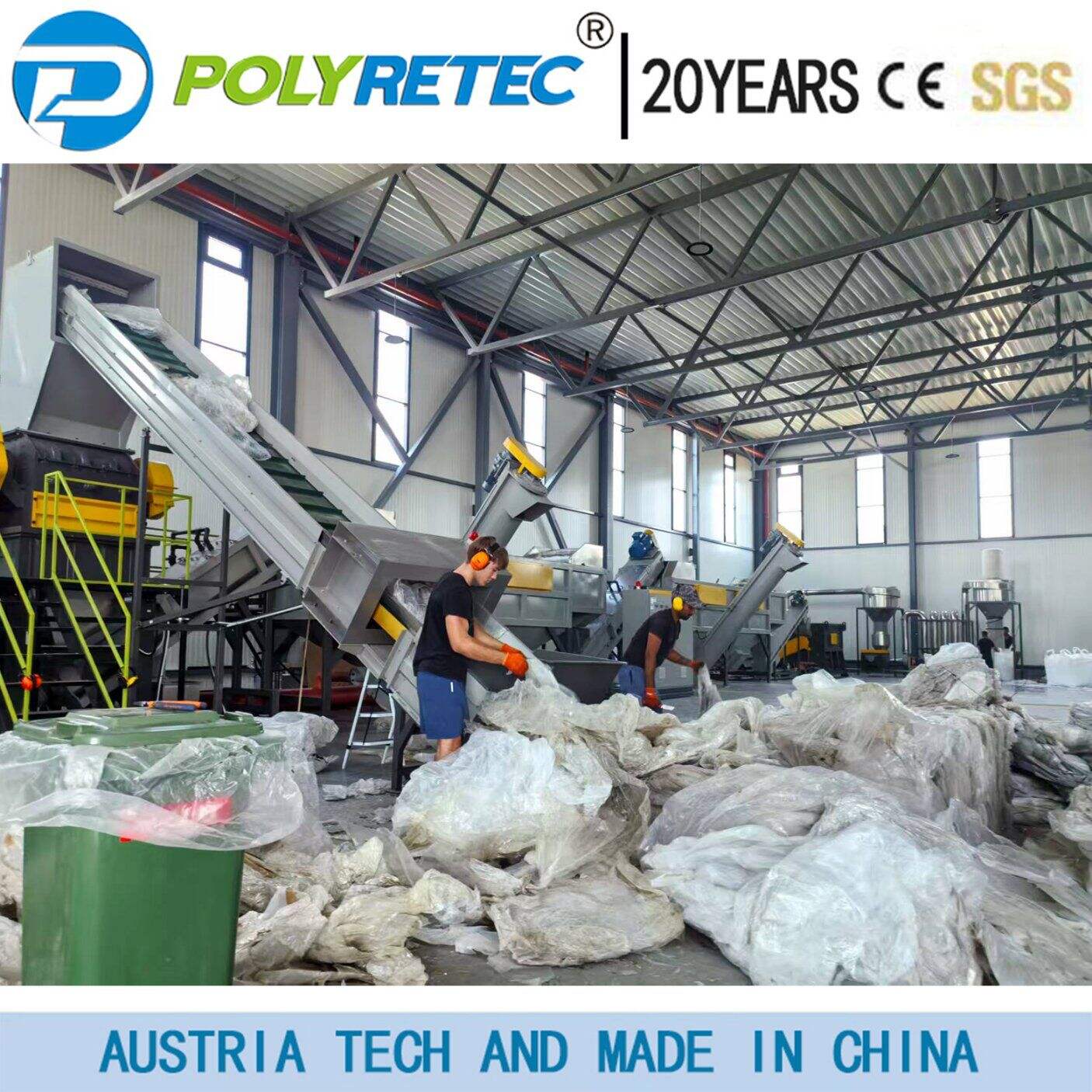

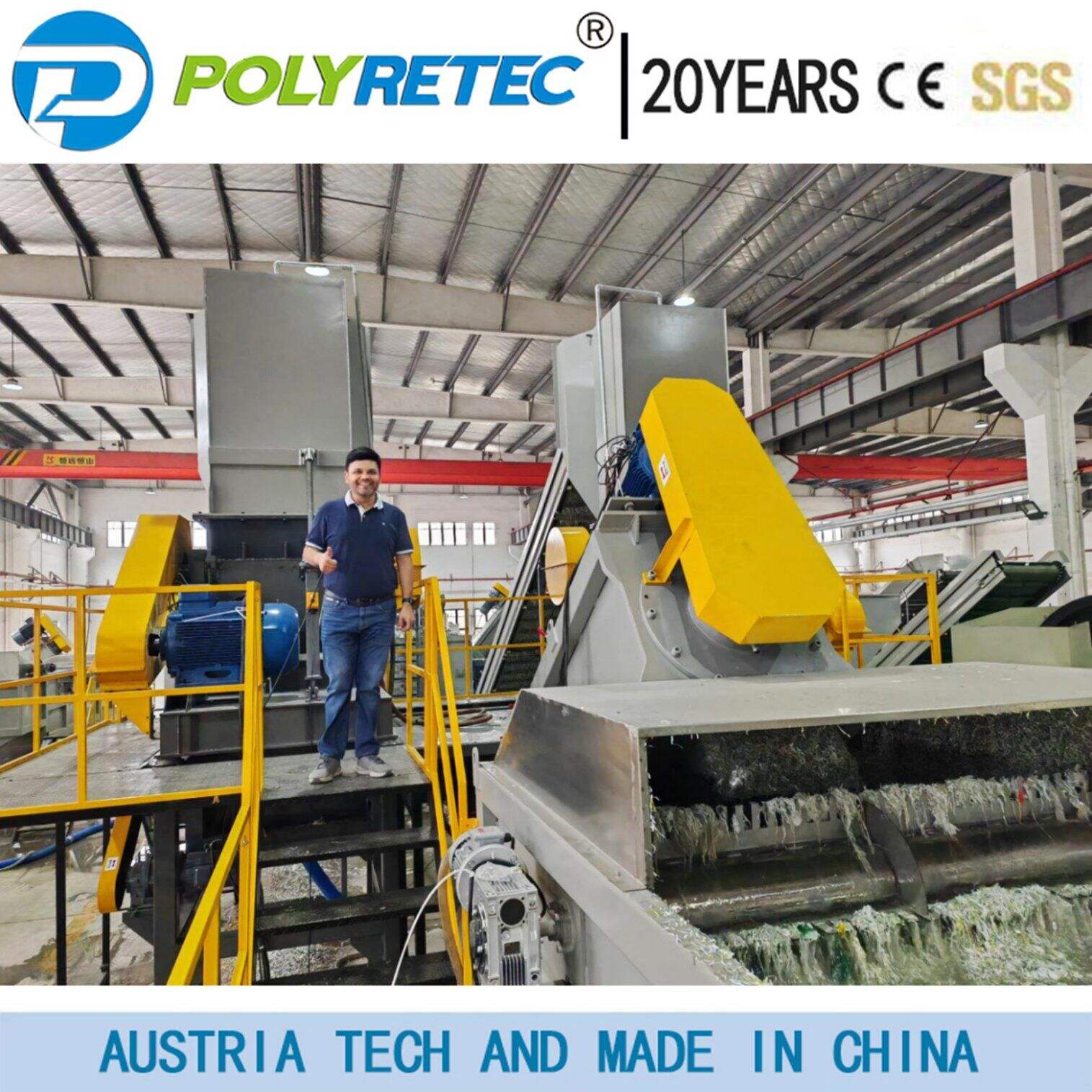

The waste bottle recycling machine represents a cutting-edge solution for efficient plastic waste management. This innovative equipment combines advanced sorting technology with automated processing capabilities to handle various types of plastic bottles efficiently. The machine employs a sophisticated recognition system that can identify and separate different plastic materials, including PET, HDPE, and PP bottles. Its core functions include bottle detection, material separation, size reduction, and automated sorting, all integrated into a streamlined process. The machine features a high-capacity input system capable of processing hundreds of bottles per hour, coupled with precision sensors that ensure accurate material identification. The technology incorporates multiple stages of processing, beginning with initial sorting, followed by contamination removal, size reduction through cutting or shredding, and final material separation. Its applications extend across various sectors, from municipal waste management facilities to beverage manufacturing plants and recycling centers. The system's modular design allows for easy maintenance and upgrades, while its user-friendly interface enables smooth operation with minimal training. Advanced safety features protect operators while maintaining optimal performance levels, making it an ideal solution for both small-scale recycling operations and large industrial facilities.