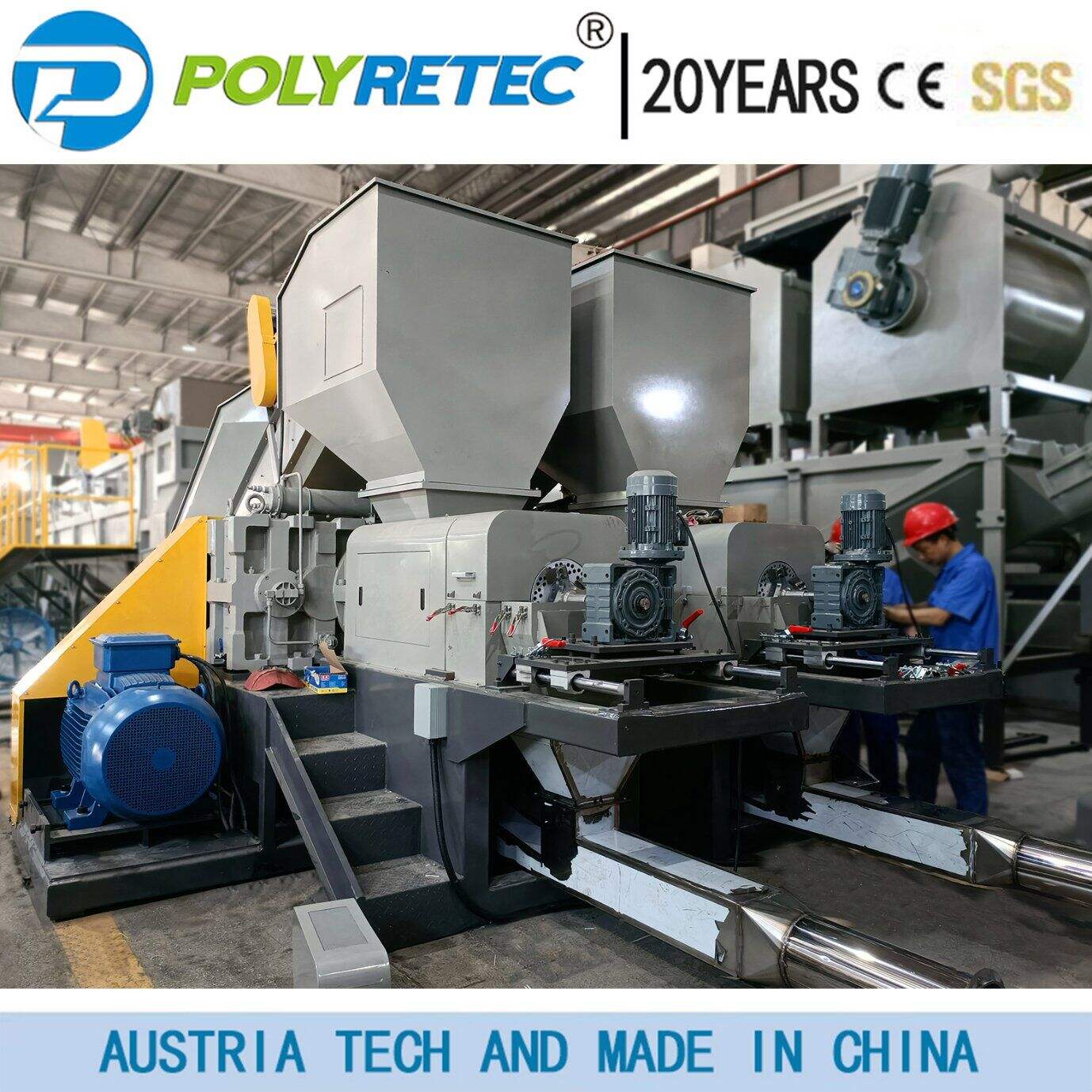

pet bottle recycling equipment

Pet bottle recycling equipment represents a comprehensive solution for transforming used PET bottles into valuable recycled materials. This advanced machinery system comprises multiple stages, including sorting, crushing, washing, and pelletizing units, all working in harmony to process post-consumer PET bottles efficiently. The equipment utilizes cutting-edge separation technology to remove contaminants, labels, and caps, ensuring only pure PET material moves forward in the recycling process. The crushing unit reduces bottles to uniform flakes, while the washing system removes adhesives and other impurities through hot water and specialized cleaning agents. Advanced friction washers and high-speed centrifugal dryers ensure thoroughly cleaned flakes. The final pelletizing stage transforms clean flakes into high-quality recycled PET pellets suitable for various applications. Modern pet bottle recycling equipment incorporates automated control systems, energy-efficient components, and precise sorting mechanisms that can process several tons of PET bottles per hour while maintaining consistent output quality. The system's modular design allows for customization based on specific capacity requirements and space constraints, making it adaptable to various facility sizes and production demands.