pet bottle crushing machine price

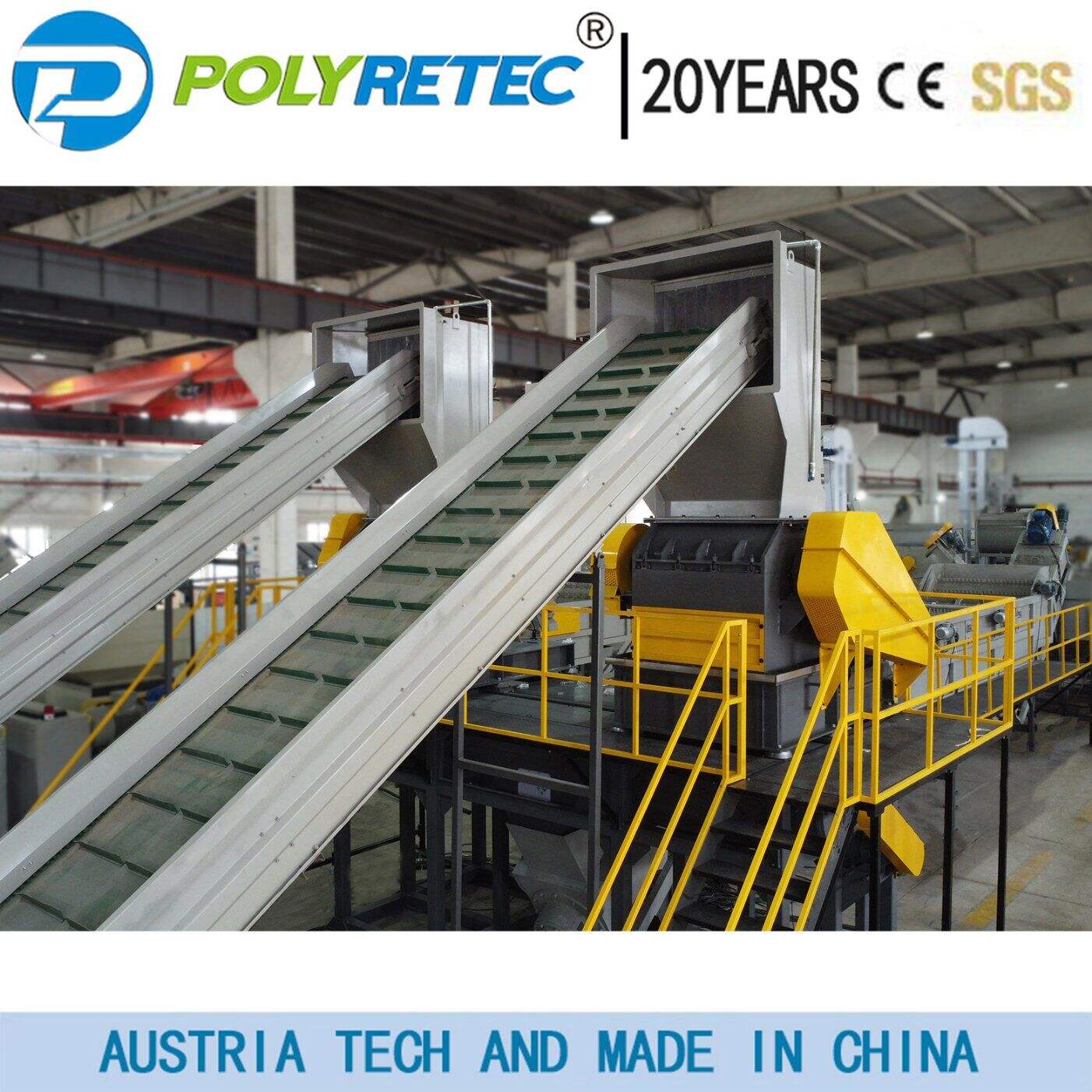

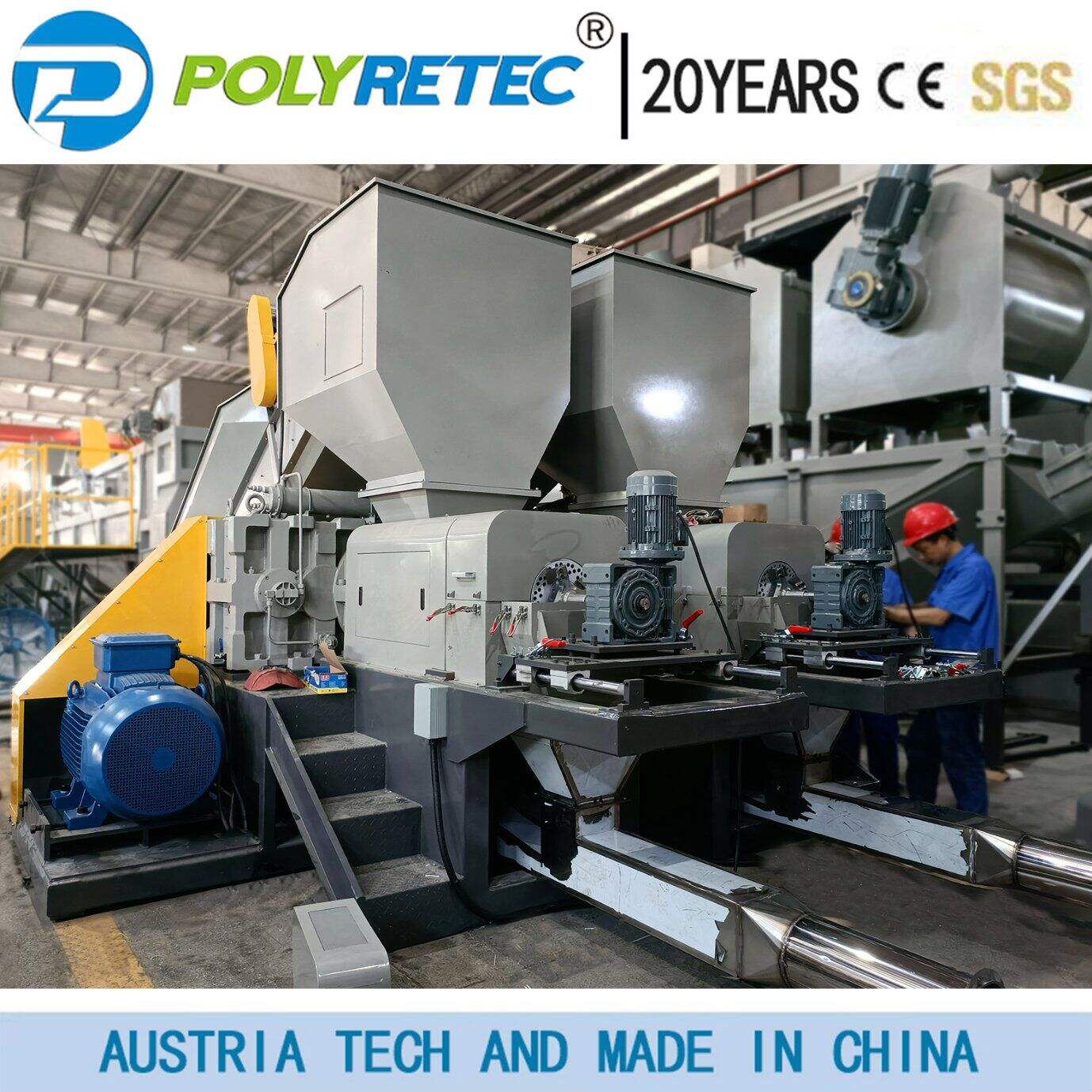

The pet bottle crushing machine price represents a significant consideration for businesses looking to invest in efficient recycling solutions. These machines, available across various price points ranging from $2,000 to $20,000, offer specialized capabilities for processing PET bottles and other plastic materials. The pricing structure typically reflects the machine's capacity, ranging from 100kg to 3000kg per hour, and its technological sophistication. Modern pet bottle crushing machines incorporate advanced features such as automatic feeding systems, precise cutting mechanisms, and adjustable crushing sizes. They utilize robust steel blades and powerful motors to ensure consistent performance and durability. The machines are designed to handle different bottle sizes and thicknesses, making them versatile for various recycling operations. The price also factors in additional features such as noise reduction technology, energy-efficient operations, and safety mechanisms. These machines play a crucial role in the recycling industry by reducing plastic waste volume, facilitating easier transportation, and preparing materials for further processing. Understanding the pet bottle crushing machine price helps businesses make informed decisions based on their specific needs and operational scale.