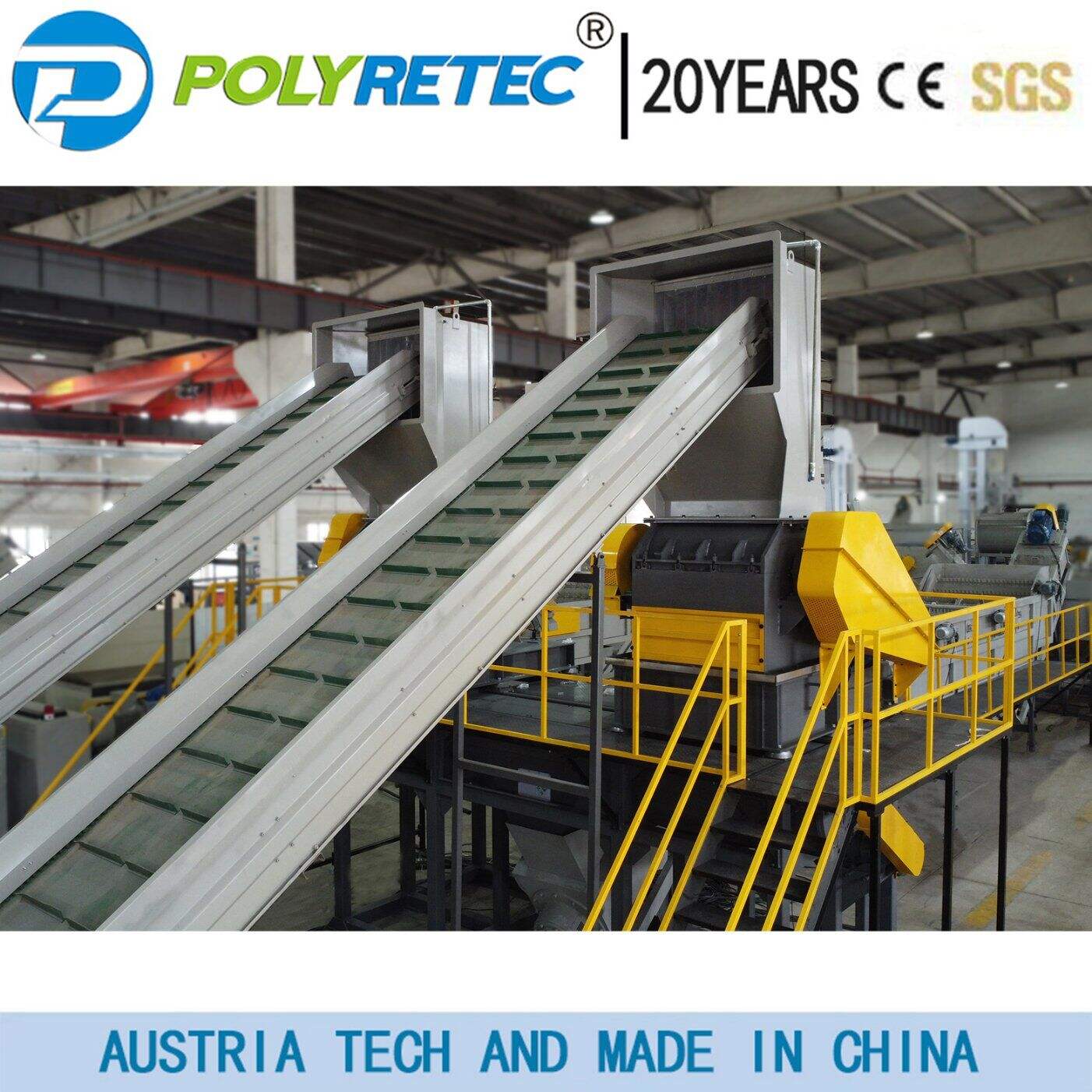

pet bottle recycling machine

The PET bottle recycling machine represents a cutting-edge solution in waste management technology, designed to efficiently process post-consumer plastic bottles into valuable recycled materials. This sophisticated system incorporates multiple stages of processing, beginning with an automated sorting mechanism that efficiently separates PET bottles from other materials. The machine utilizes advanced sensors and artificial intelligence to identify and remove contaminants, ensuring the highest quality output. At its core, the system features a high-capacity crushing unit that reduces bottles to optimally sized flakes, followed by a thorough washing process that removes labels, adhesives, and other impurities. The technology includes a state-of-the-art drying system that ensures the processed material meets industry standards for moisture content. With processing capabilities ranging from 500 to 3000 kg per hour, these machines can be scaled to meet various operational needs. The system's integrated control panel provides real-time monitoring and adjustment capabilities, while its energy-efficient design minimizes operational costs. The final output consists of clean, high-quality PET flakes that can be directly used in various manufacturing processes, contributing to a circular economy.