pet bottle recycling machine manufacturers

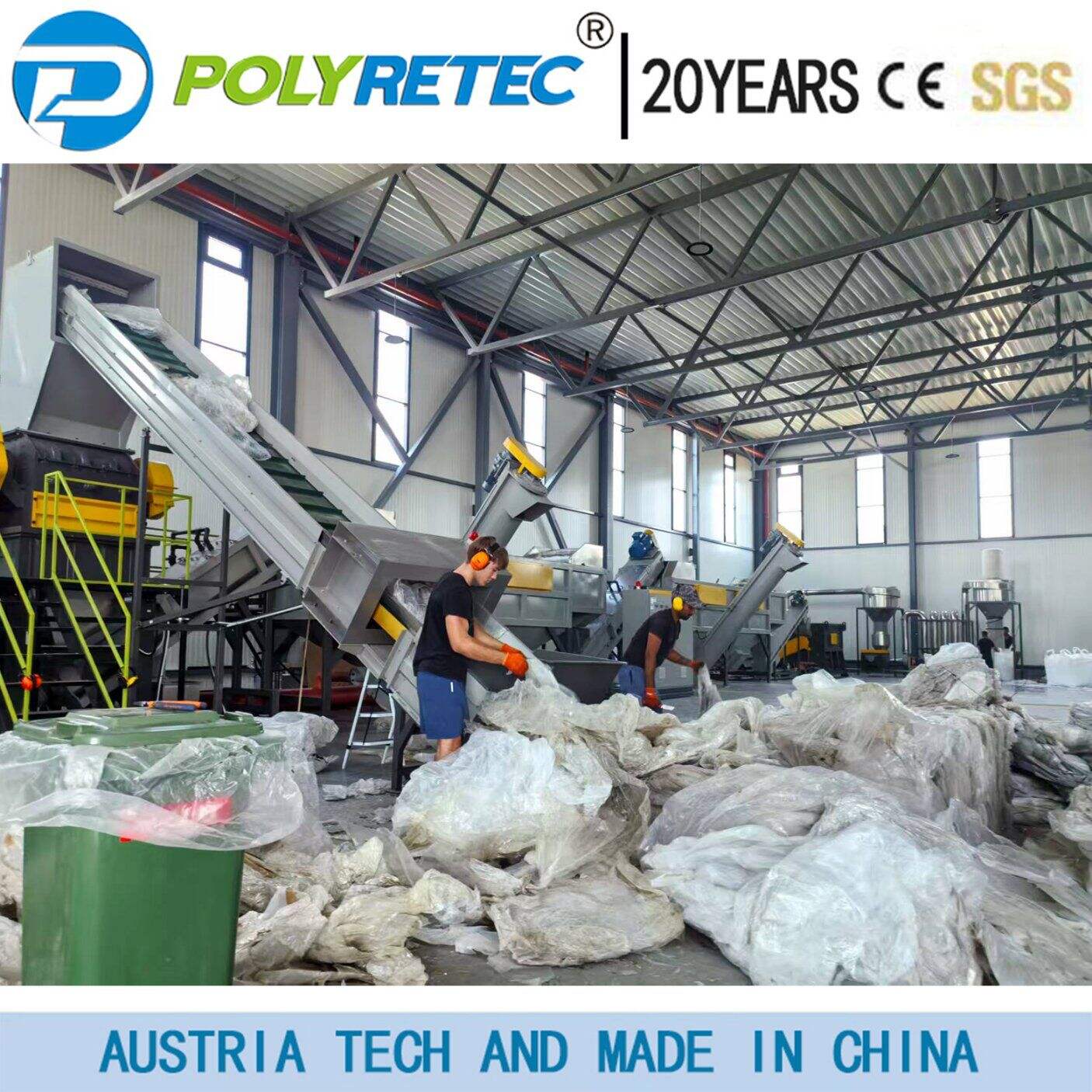

Pet bottle recycling machine manufacturers are leading innovators in sustainable waste management solutions, specializing in the design and production of advanced recycling equipment. These manufacturers develop sophisticated machines that efficiently process post-consumer PET bottles into valuable recycled materials. Their equipment typically incorporates multiple stages of processing, including sorting, grinding, washing, and pelletizing systems. Modern pet bottle recycling machines feature automated sorting mechanisms with optical sensors that can differentiate between various types of plastics, ensuring high purity output. The manufacturing process emphasizes precision engineering, with machines capable of processing hundreds of kilograms of PET bottles per hour while maintaining consistent quality standards. These manufacturers also integrate smart technology features such as real-time monitoring systems, energy-efficient components, and user-friendly control interfaces. Their machines are designed to handle various bottle sizes and colors, incorporating advanced cleaning systems that remove contaminants and labels effectively. Many manufacturers offer customizable solutions to meet specific client requirements, from small-scale recycling operations to industrial-scale facilities. The industry continues to evolve with innovations in processing efficiency, output quality, and environmental sustainability.