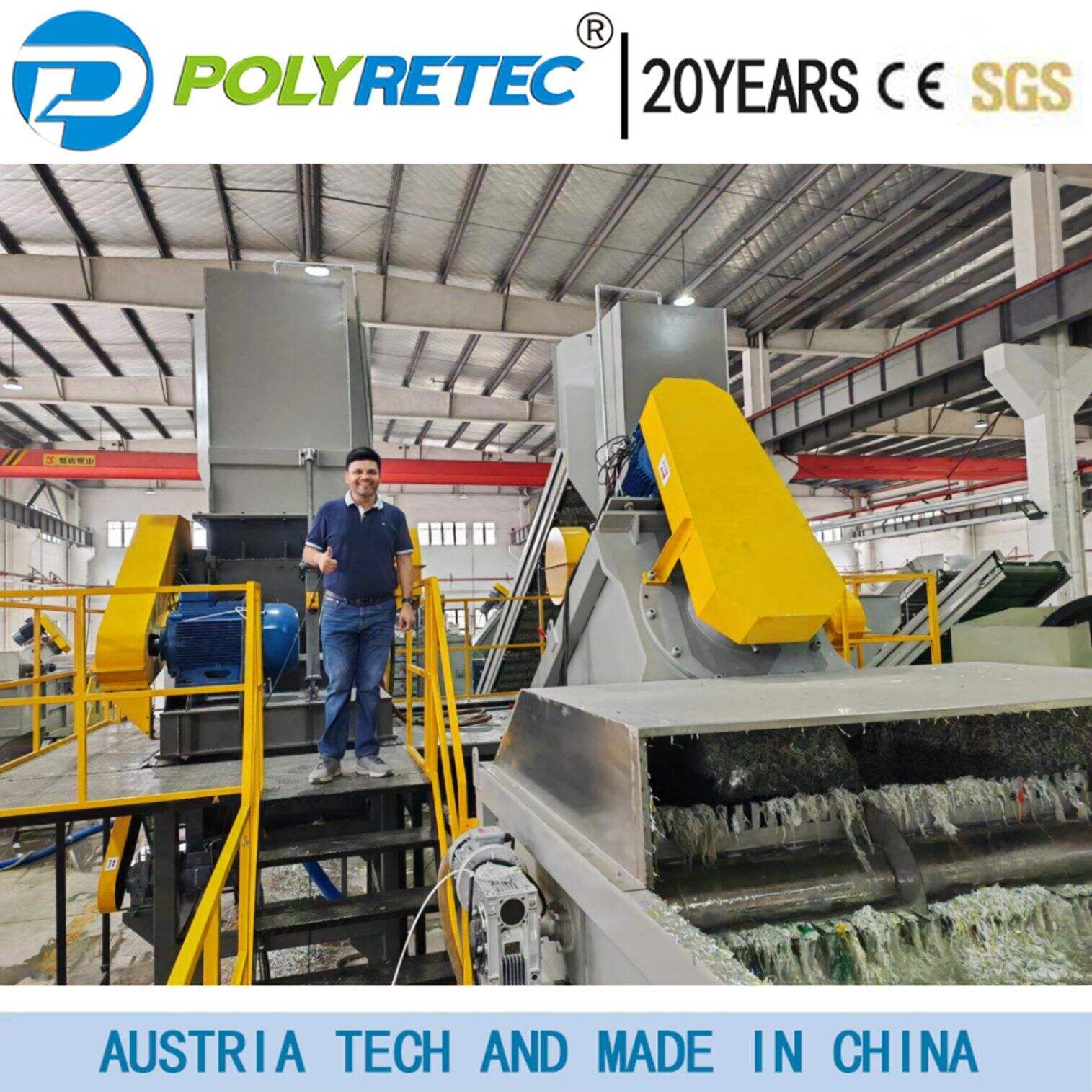

old plastic recycling machine

The old plastic recycling machine represents a fundamental solution in the waste management industry, designed to process various types of plastic waste into reusable materials. This robust equipment incorporates a comprehensive system of sorting, crushing, washing, and pelletizing mechanisms to transform plastic waste into valuable recycled materials. The machine features a powerful motor system that drives multiple processing stages, including a primary shredder that reduces large plastic items into manageable pieces, followed by a washing system that removes contaminants and labels. The granulator then further reduces the plastic fragments to uniform sizes, while the melting and extrusion components transform the processed material into pellets suitable for manufacturing new products. This versatile machine can handle multiple plastic types, including PE, PP, PVC, and PET, making it an essential tool for recycling facilities, manufacturing plants, and waste management operations. The system's modular design allows for easy maintenance and component replacement, ensuring long-term operational efficiency and reliability.