plastic disposal machine price

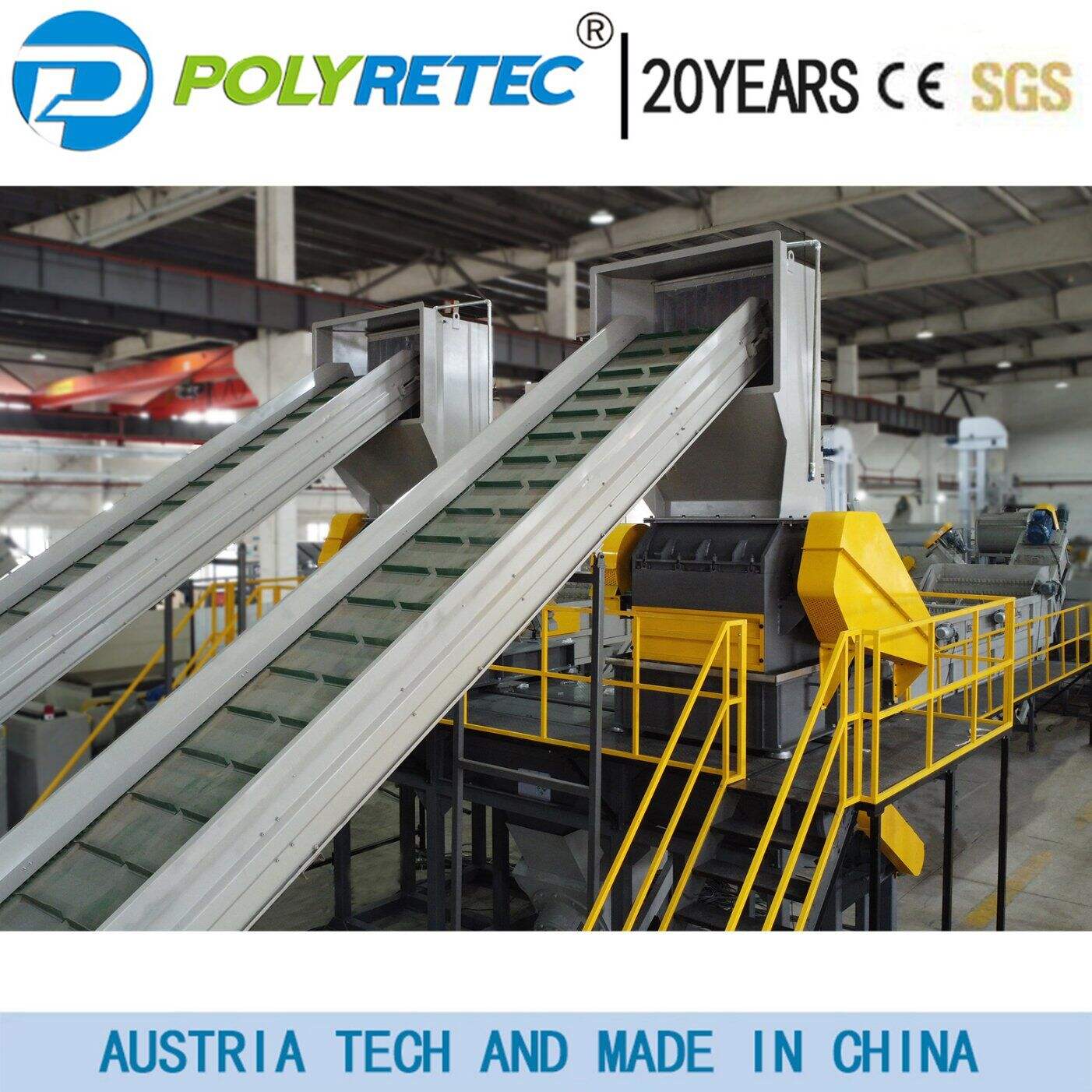

The plastic disposal machine price represents a significant investment in sustainable waste management technology. These machines, available across various price points from $5,000 to $50,000, offer comprehensive solutions for processing different types of plastic waste. The pricing structure typically reflects the machine's capacity, processing capabilities, and technological features. Entry-level models, suitable for small businesses, usually handle 100-200 kg per hour, while industrial-grade machines can process up to 1000 kg hourly. The price includes essential features such as automatic feeding systems, precise temperature control mechanisms, and advanced sorting capabilities. Modern units incorporate smart monitoring systems, energy-efficient operations, and variable speed controls to optimize performance. The machines utilize advanced shredding technology, capable of processing multiple plastic grades, from PET to HDPE. The price also factors in safety features, including emergency shut-off systems and overload protection. These machines typically offer customizable settings for different plastic types, ensuring optimal processing efficiency and output quality. The investment often includes installation support, operational training, and initial maintenance coverage.