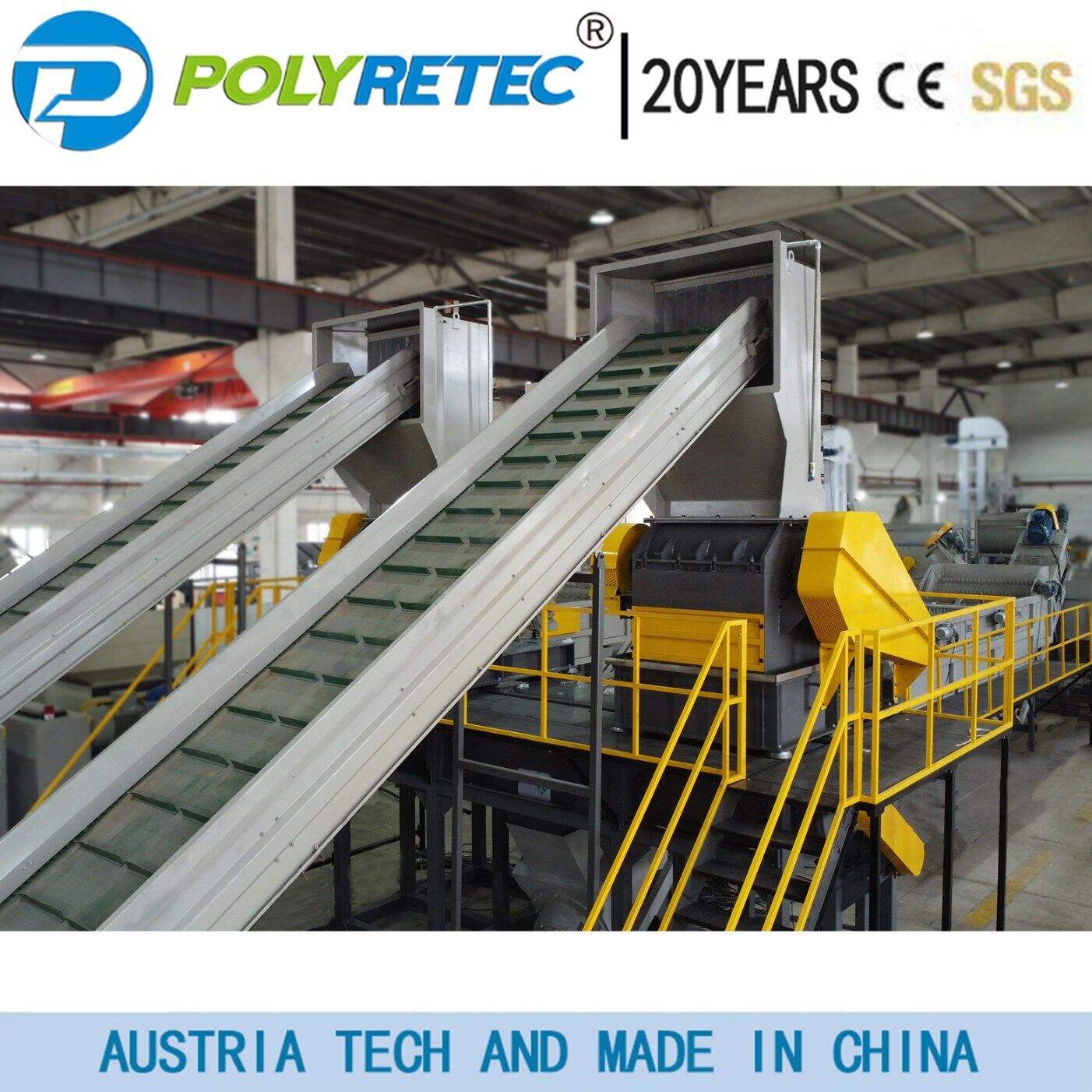

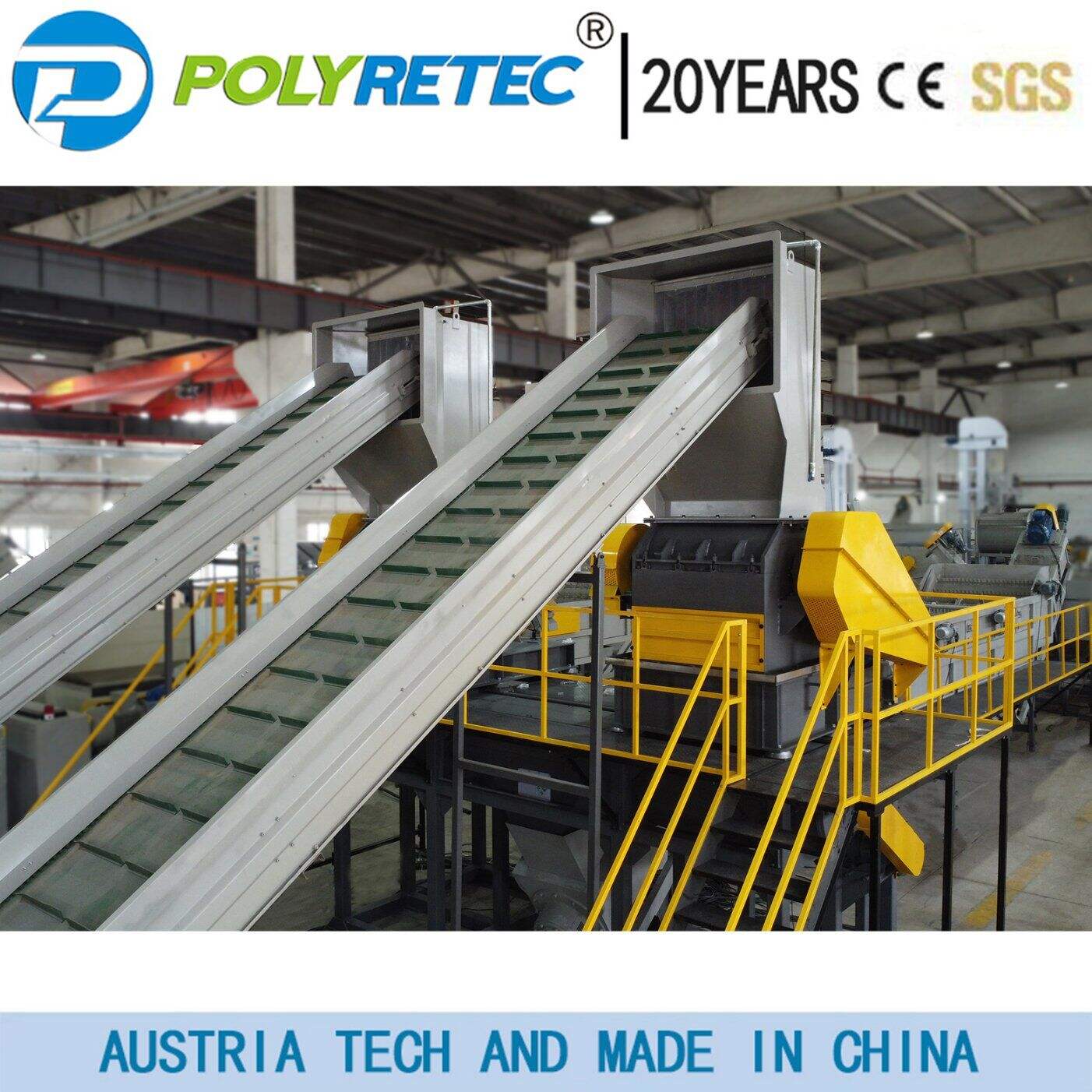

mini plastic recycling machine

The mini plastic recycling machine represents a revolutionary solution for small-scale plastic waste management. This compact yet powerful device efficiently processes various types of plastic materials, transforming them into reusable pellets or flakes. The machine incorporates a sophisticated shredding mechanism that breaks down plastic items into smaller pieces, followed by a heating and extrusion system that melts and reshapes the material. With its advanced temperature control system and precision cutting mechanism, it ensures consistent output quality. The machine typically processes 20-50 kg of plastic per hour, making it ideal for small businesses, workshops, and community recycling initiatives. Its user-friendly interface allows operators to adjust processing parameters such as temperature, cutting speed, and material feed rate. The system includes safety features like emergency shut-off switches and overload protection. This versatile machine can handle multiple plastic types including PE, PP, PS, and ABS, making it adaptable to various recycling needs. The compact design requires minimal floor space while maintaining professional-grade performance, and its energy-efficient operation helps reduce operating costs. Regular maintenance is straightforward, with easily accessible components and clear maintenance schedules provided.