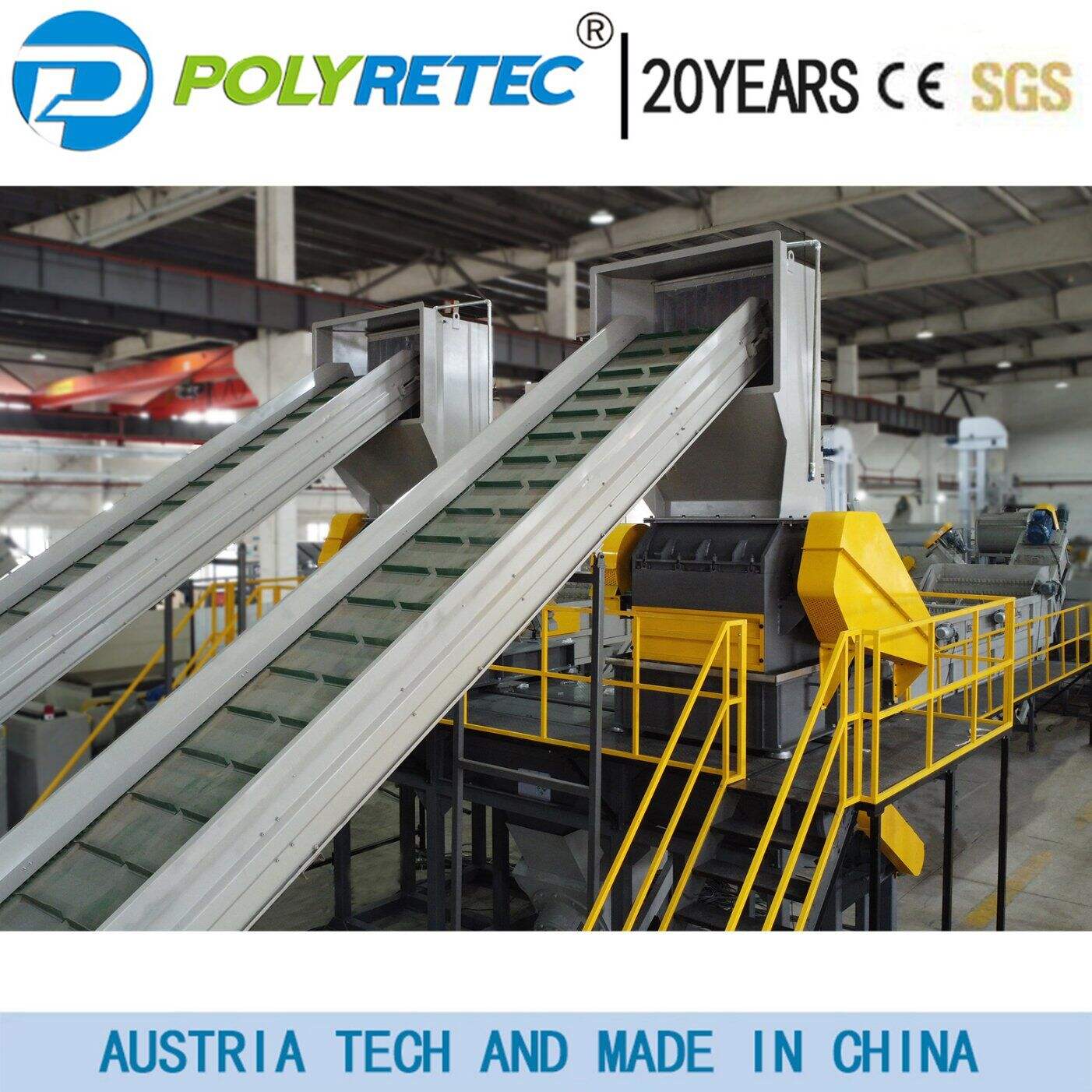

simple plastic recycling machine

A simple plastic recycling machine represents a revolutionary solution in waste management, designed to transform plastic waste into valuable recycled materials. This compact yet powerful equipment operates through a straightforward process that includes sorting, shredding, washing, and pelletizing capabilities. The machine efficiently processes various types of plastics, including PET, HDPE, and PP, converting them into reusable plastic pellets or flakes. Its user-friendly interface allows operators to control temperature, speed, and output quality with precision. The machine's modular design incorporates essential components such as a feeding system, cutting chamber, washing unit, and extrusion mechanism, all working in harmony to ensure consistent output quality. With processing capabilities typically ranging from 100 to 300 kg per hour, depending on the model and material type, these machines offer scalable solutions for different operational needs. The technology employs advanced heating elements and cooling systems to maintain optimal processing temperatures, while built-in safety features protect operators and ensure smooth operation. This versatile equipment finds applications in small to medium-sized recycling facilities, manufacturing plants, and waste management centers, providing an effective means to contribute to environmental sustainability while creating valuable recycled materials.