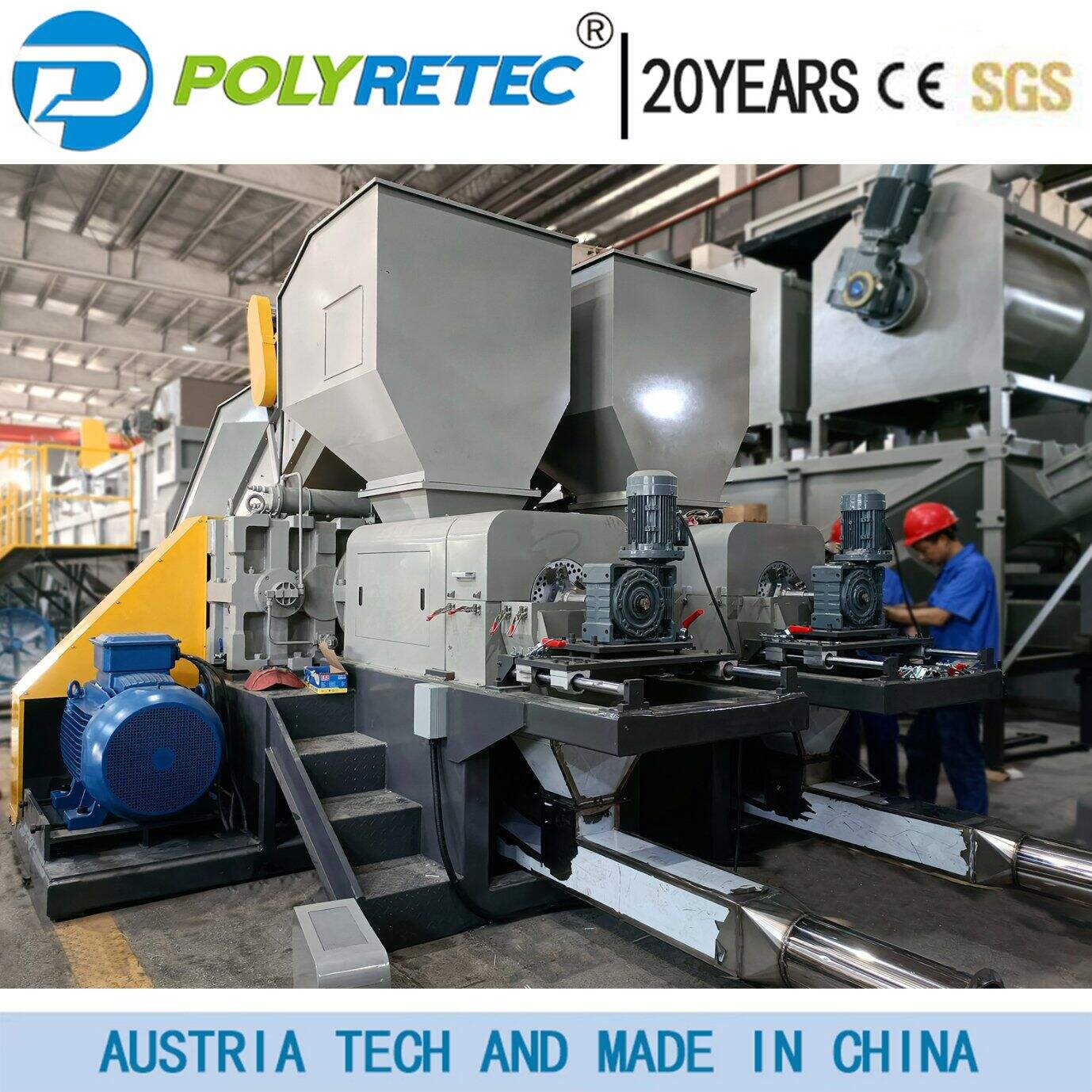

plastic waste recycling equipment

Plastic waste recycling equipment represents a comprehensive solution for transforming plastic waste into valuable resources. This advanced machinery incorporates multiple processing stages, including sorting, crushing, washing, drying, and pelletizing systems. The equipment utilizes cutting-edge separation technology to effectively sort different types of plastics, ensuring optimal recycling outcomes. The crushing system features hardened steel blades that can process various plastic materials, from rigid containers to flexible films. Advanced washing systems remove contaminants and labels, while the drying process employs energy-efficient heating elements to prepare materials for pelletizing. The pelletizing system transforms processed plastic into uniform, high-quality pellets suitable for manufacturing new products. This equipment can handle multiple plastic types, including PET, HDPE, LDPE, and PP, with processing capacities ranging from 500 to 3000 kg per hour. The system's modular design allows for customization based on specific requirements, while automated controls ensure consistent output quality and operational efficiency.