buy plastic recycling machine

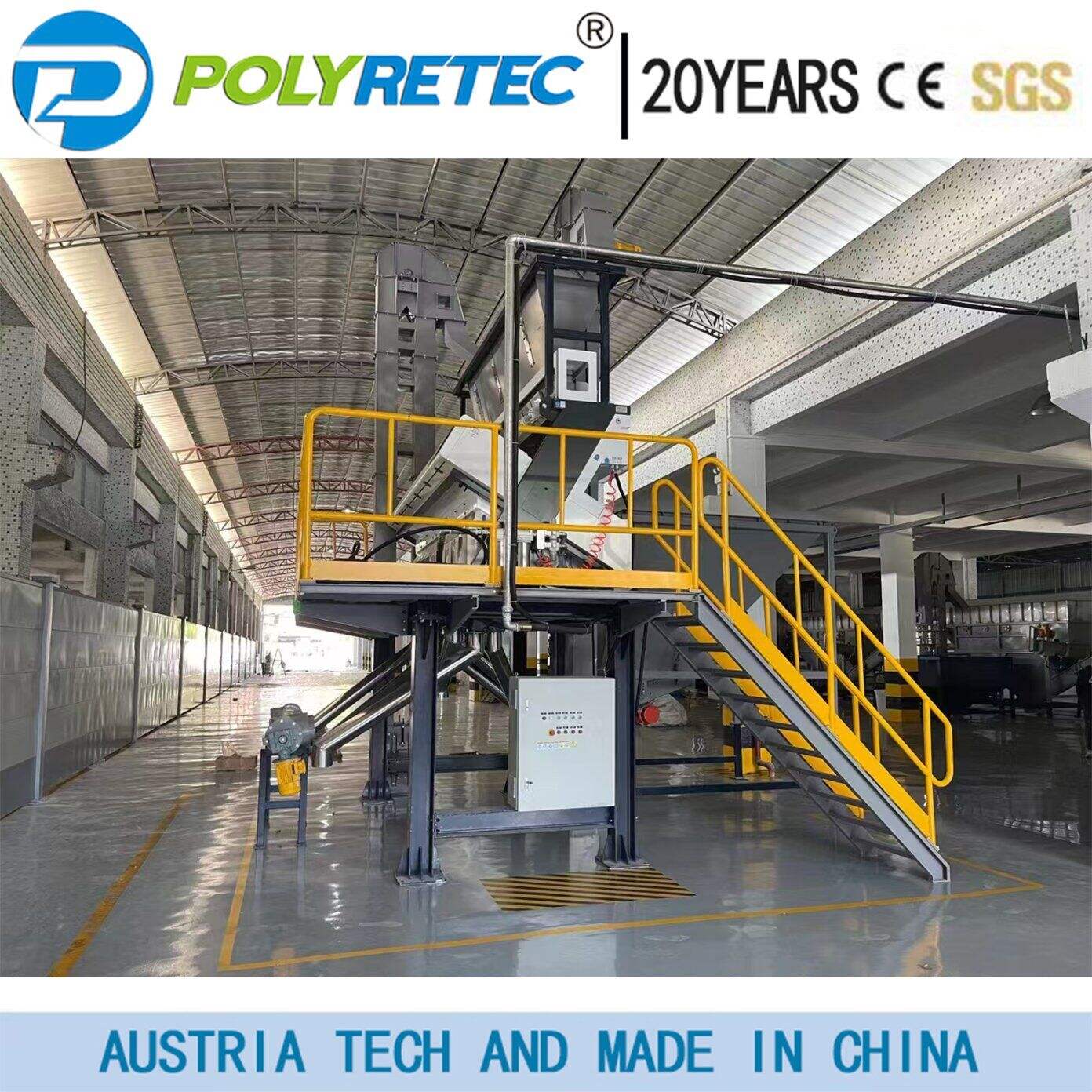

A plastic recycling machine represents a significant investment in sustainable manufacturing, offering comprehensive solutions for processing various types of plastic waste into reusable materials. These sophisticated systems integrate multiple components including shredders, washers, dryers, and extruders to transform plastic waste into valuable recycled pellets or flakes. The machine's advanced sorting mechanisms can effectively separate different plastic types, ensuring high-quality output materials. Operating with precision controls and automated systems, these machines can process several hundred kilograms of plastic per hour, depending on the model and configuration. The technology incorporates energy-efficient motors and heating systems, optimizing operational costs while maintaining consistent production quality. Modern plastic recycling machines feature user-friendly interfaces that allow operators to monitor and adjust processing parameters in real-time, ensuring optimal performance across different plastic grades. These machines are designed with safety features including emergency shut-off systems and protective guards, making them suitable for both industrial and commercial applications. The versatility of these systems allows for processing various plastic types including PET, HDPE, LDPE, and PP, making them valuable assets for recycling facilities, manufacturing plants, and waste management operations.