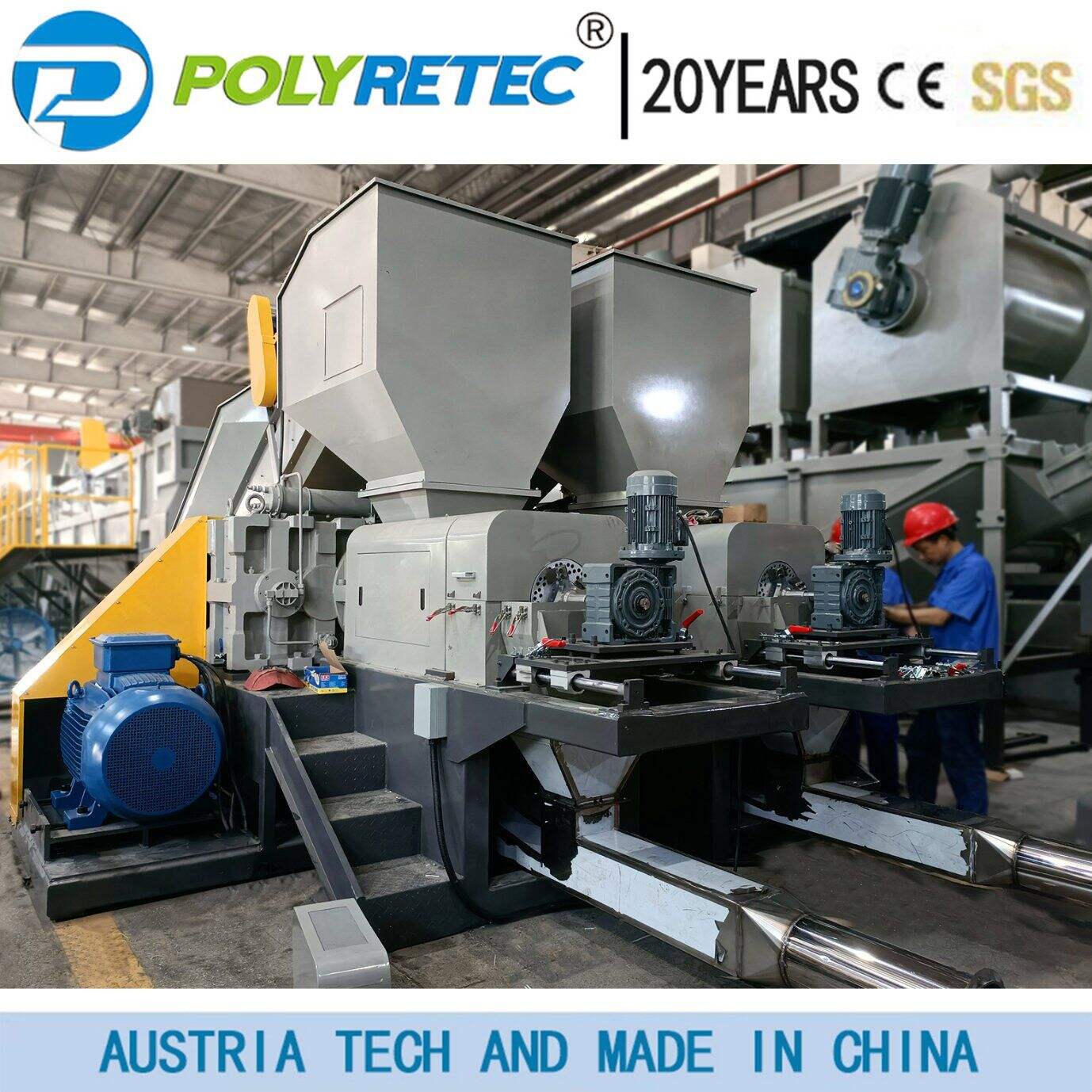

fully automatic plastic recycling machine

The fully automatic plastic recycling machine represents a cutting-edge solution for transforming plastic waste into valuable resources. This advanced system integrates multiple processes including sorting, crushing, washing, drying, and pelletizing into a seamless operation. The machine employs sophisticated sensors and artificial intelligence to automatically identify and separate different types of plastics, ensuring optimal processing efficiency. Its high-precision crushing system reduces plastics to uniform sizes, while the advanced washing system removes contaminants and labels. The integrated drying system ensures moisture content meets industry standards, and the pelletizing unit converts processed material into high-quality recycled plastic pellets. With processing capacities ranging from 500 to 3000 kg per hour, these machines can handle various plastic types including PET, HDPE, LDPE, and PP. The system features real-time monitoring capabilities and automated quality control mechanisms that maintain consistent output quality. Energy-efficient components and water recycling systems make it environmentally sustainable, while its compact design optimizes floor space usage. The machine's intuitive control panel allows for easy operation and quick parameter adjustments, making it suitable for both small recycling facilities and large industrial operations.