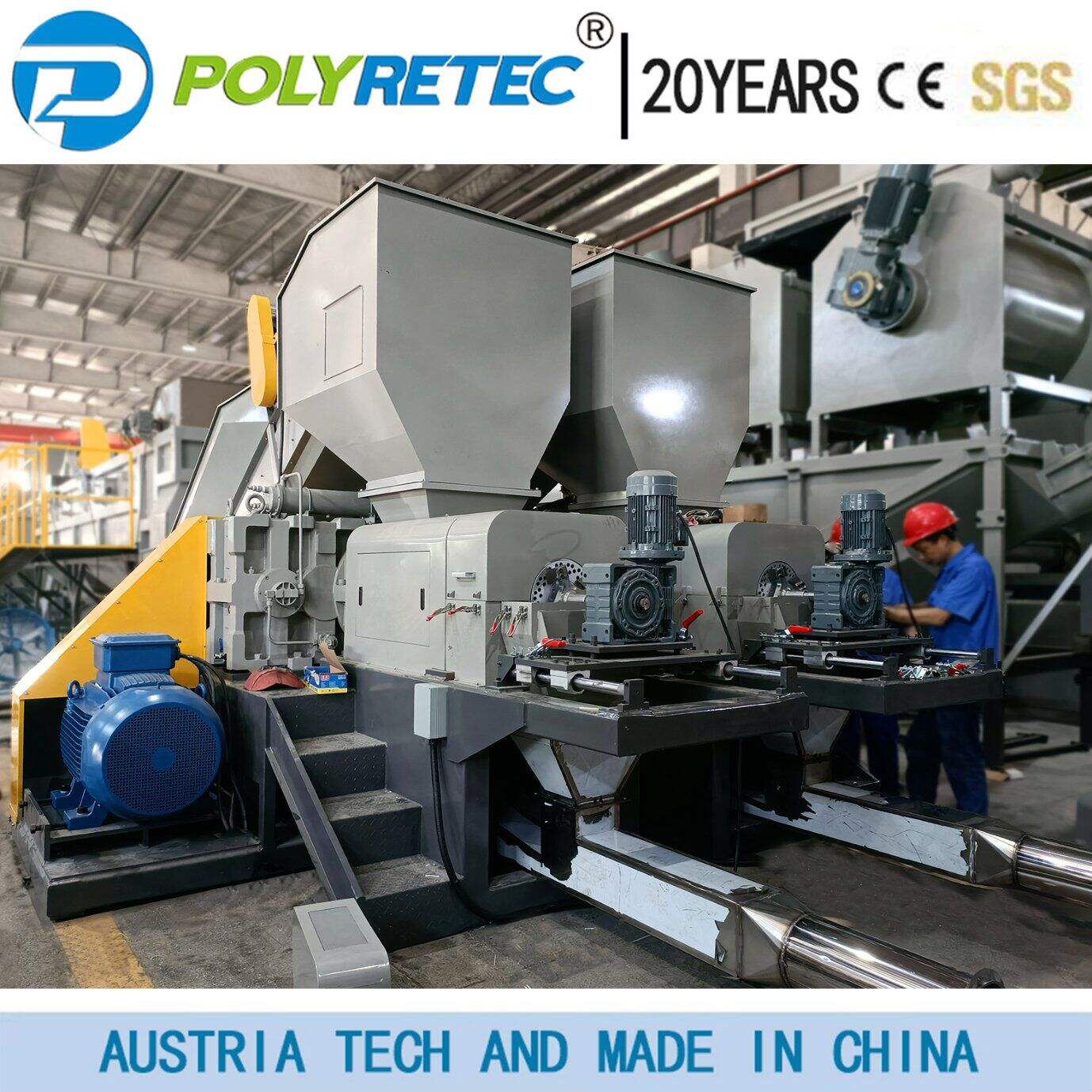

plastic water bottle recycling machine

The plastic water bottle recycling machine represents a cutting-edge solution for efficient waste management and environmental sustainability. This advanced system automates the entire recycling process, from initial bottle collection to final material processing. The machine employs sophisticated sorting technology that can process up to 1,500 bottles per hour, utilizing optical sensors to differentiate between various plastic types and remove contaminants. Its compact design incorporates a high-efficiency crushing mechanism that reduces bottles to uniform size particles, optimizing storage space and preparing materials for further processing. The system features an integrated washing unit that removes labels, dirt, and residual contents, ensuring high-quality recycled material output. The machine's smart control panel enables operators to monitor performance metrics, adjust processing parameters, and track recycling volumes in real-time. Additionally, it includes an automatic baling system that compresses processed materials into manageable units for transport. This technology is particularly valuable for recycling facilities, beverage manufacturers, and waste management companies seeking to enhance their recycling capabilities while reducing operational costs.