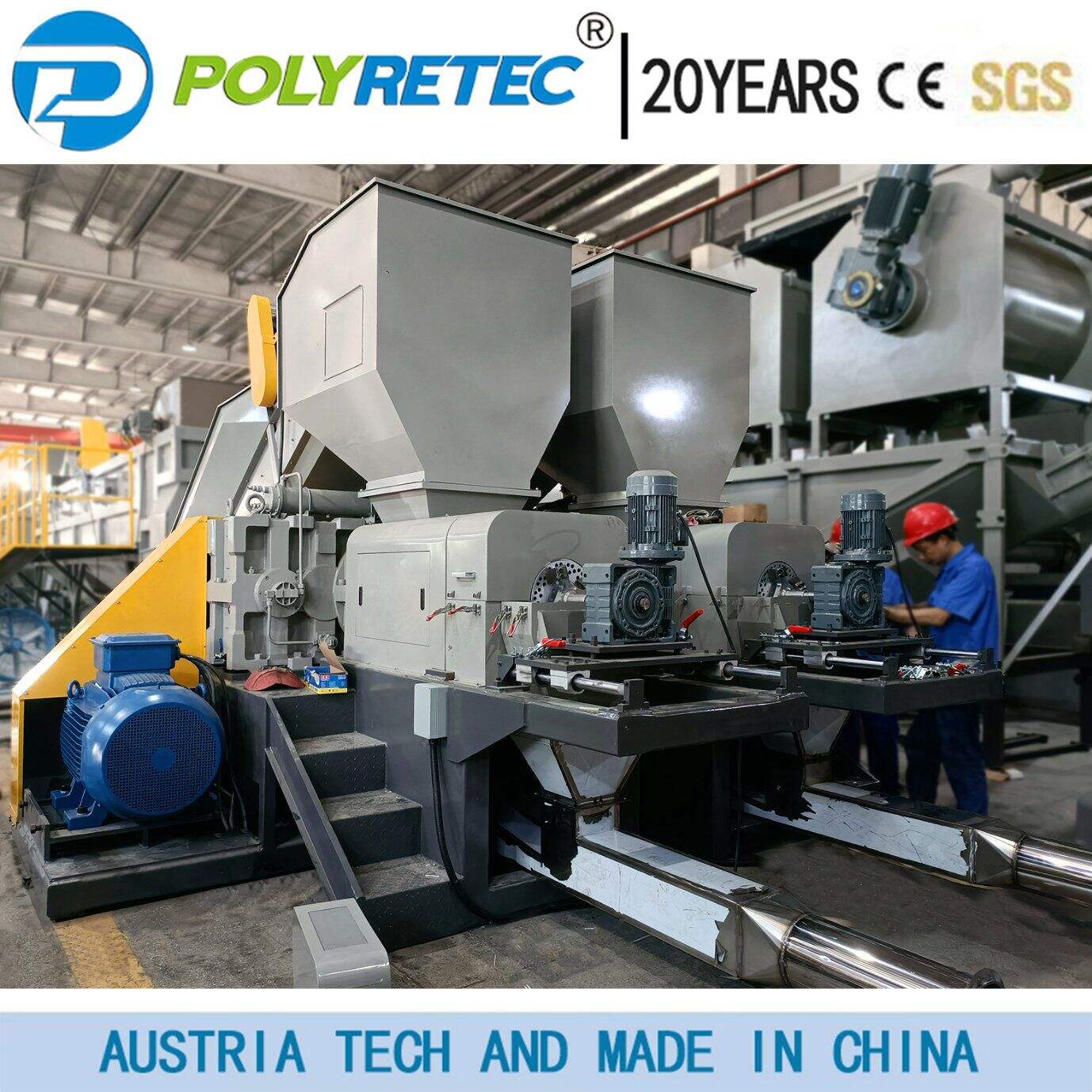

plastic recycling machine price

The plastic recycling machine price represents a crucial investment consideration in the recycling industry, reflecting various factors including capacity, technology level, and manufacturing quality. Modern plastic recycling machines typically range from $10,000 to $200,000, depending on their specifications and capabilities. These machines incorporate advanced sorting mechanisms, washing systems, and pelletizing technologies that transform waste plastic into reusable materials. The price variation is primarily influenced by processing capacity, which can range from 100 kg to several tons per hour, automation level, and additional features such as integrated quality control systems. High-end models often include sophisticated sensors for material identification, multiple-stage cleaning processes, and energy-efficient motors that optimize operational costs. The investment consideration should account for long-term returns through reduced waste management costs, revenue from recycled materials, and environmental compliance benefits. When evaluating plastic recycling machine prices, it's essential to consider factors such as maintenance requirements, spare parts availability, and operational efficiency to determine the total cost of ownership.