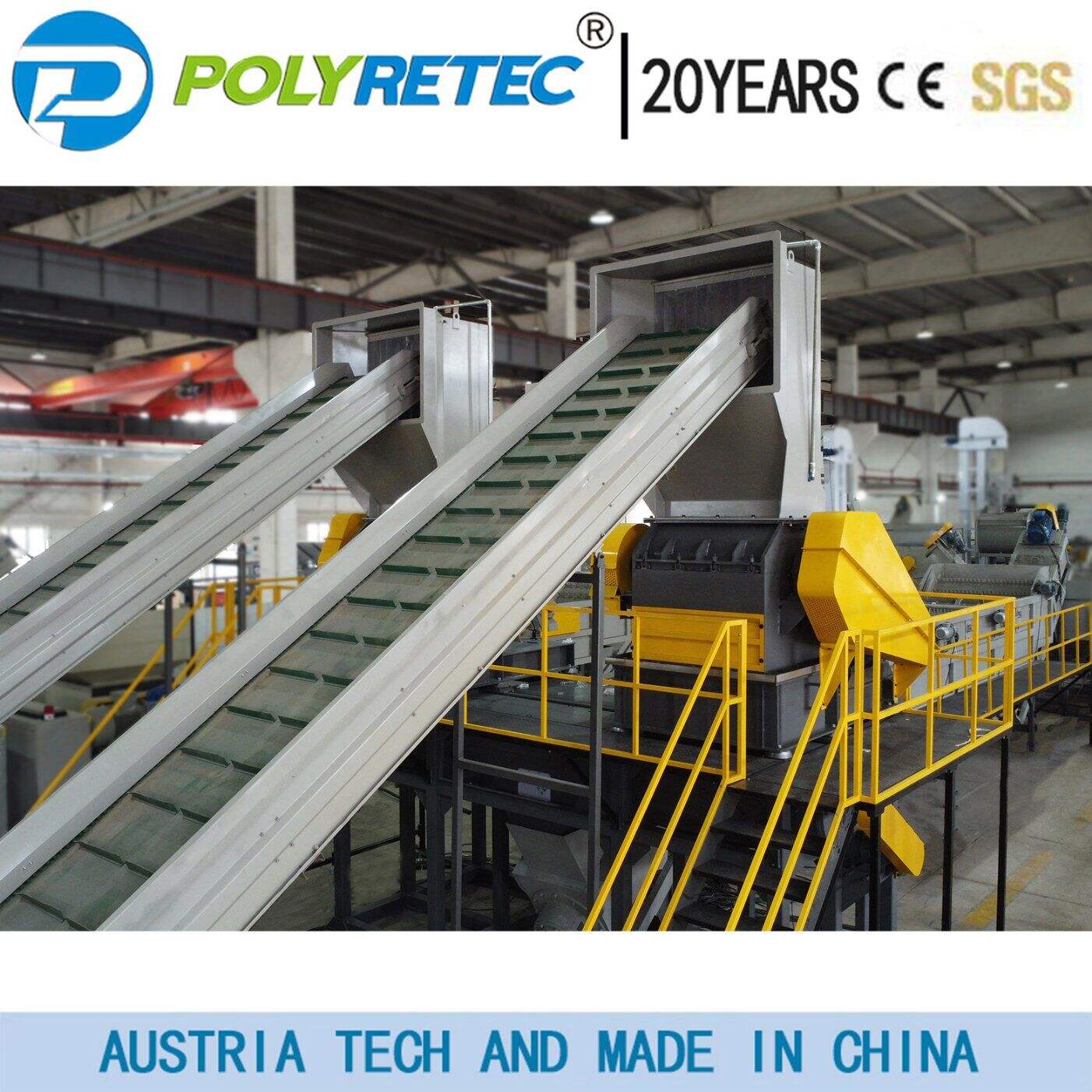

plastic pelletizing recycling machine

The plastic pelletizing recycling machine represents a cutting-edge solution in waste plastic processing, transforming various plastic waste materials into high-quality pellets suitable for reuse in manufacturing. This advanced system incorporates multiple stages of processing, beginning with a robust feeding mechanism that handles different types of plastic waste, including post-consumer and post-industrial materials. The machine features an efficient melting system equipped with precisely controlled heating zones that ensure optimal plastification of the material. The heart of the system lies in its advanced extrusion mechanism, where the melted plastic is homogenized and filtered to remove impurities. The pelletizing section utilizes either underwater or strand pelletizing technology, producing uniform pellets with consistent size and shape. The machine's intelligent control system maintains stable operation parameters, while its automatic temperature control ensures product quality. With processing capacities ranging from 100 to 1000 kg per hour, the machine accommodates various production scales. Its modular design allows for easy maintenance and component replacement, while built-in safety features protect operators and maintain consistent production quality.