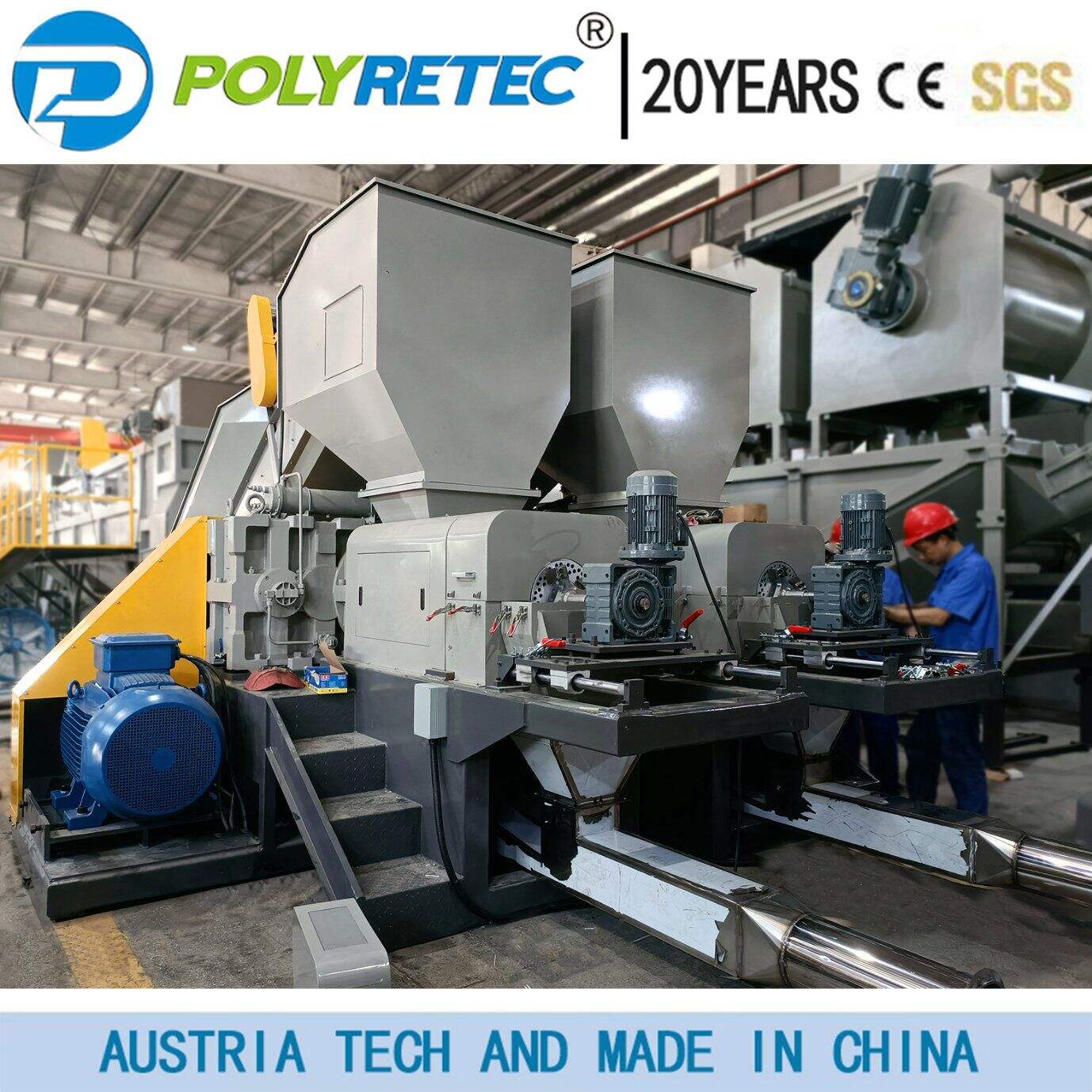

small plastic recycling machine

The small plastic recycling machine represents a breakthrough in sustainable waste management technology, designed specifically for small to medium-scale operations. This compact yet powerful unit efficiently processes various types of plastic waste, including PET, HDPE, LDPE, and PP materials, transforming them into reusable plastic granules. The machine features an integrated system comprising a shredder, washing unit, drying mechanism, and extrusion component, all working in seamless coordination. Operating at temperatures between 180-250°C, it can process 100-200 kg of plastic per hour, making it ideal for small businesses and community recycling initiatives. The machine's advanced control system maintains precise temperature regulation and material flow, ensuring consistent output quality. Its space-efficient design, typically requiring only 50-100 square meters of installation area, makes it suitable for various settings. The system incorporates safety features including emergency shut-off mechanisms and overload protection, while its energy-efficient motors help maintain reasonable operating costs. The machine's modular construction allows for easy maintenance and component replacement, ensuring long-term reliability and operational efficiency.