extruder plastic recycling

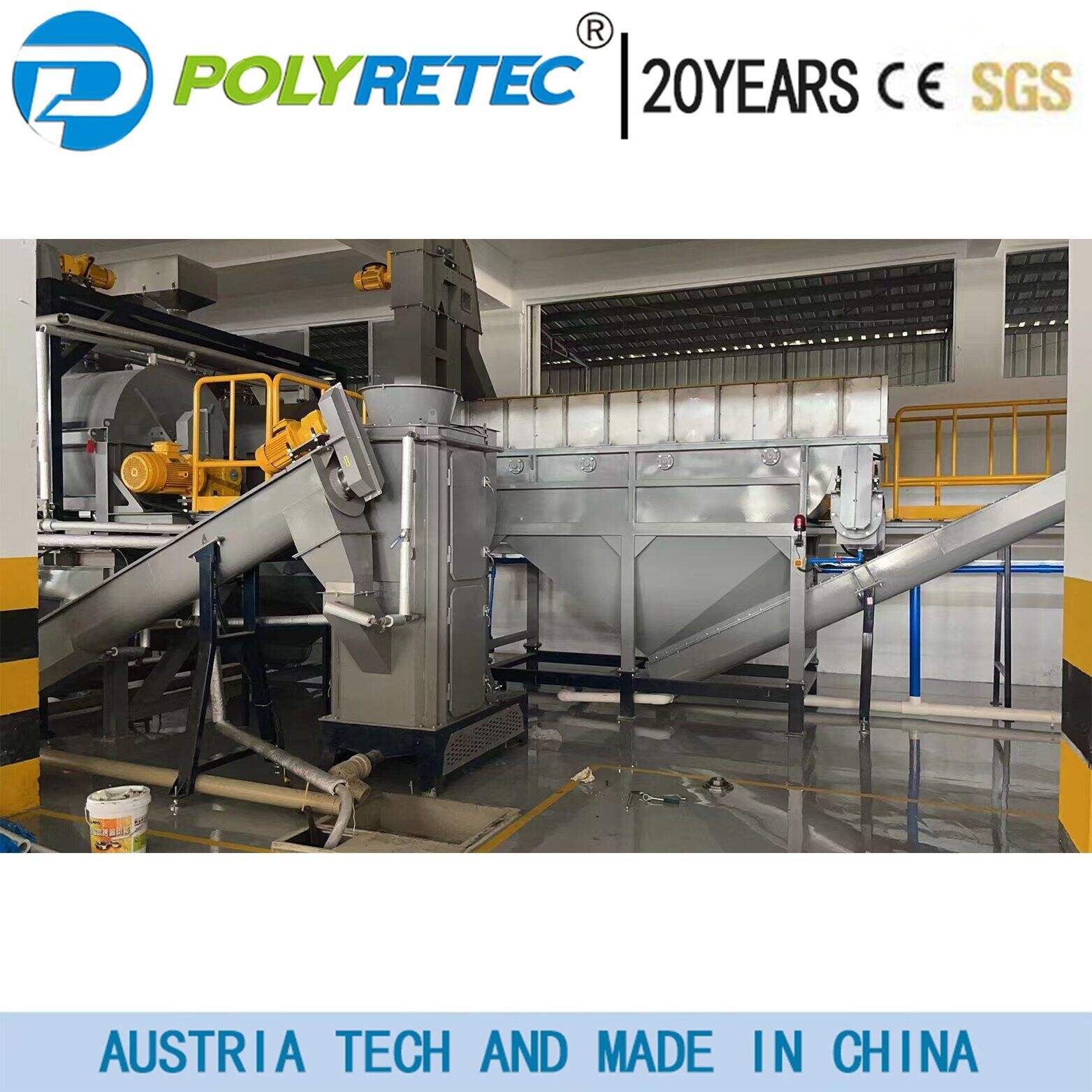

Extruder plastic recycling represents a cutting-edge solution in sustainable waste management, transforming post-consumer and industrial plastic waste into valuable recycled materials. This advanced process begins with the careful sorting and cleaning of plastic waste, followed by size reduction through grinding or shredding. The heart of the system is the extruder machine, which employs precise temperature control and mechanical force to melt and homogenize the plastic material. As the material moves through the barrel, it undergoes intensive mixing and degassing, ensuring uniform quality and removing contaminants. The molten plastic is then forced through a die to form new plastic products or pellets. Modern extruder systems feature computerized control panels, allowing operators to monitor and adjust critical parameters such as temperature, pressure, and screw speed in real-time. The technology accommodates various plastic types, including PE, PP, PS, and PVC, making it versatile for different recycling needs. Advanced systems may include additional components like metal detectors, automatic screen changers, and pelletizing systems, enhancing the quality of the final product. This process not only contributes to environmental sustainability but also provides economic benefits through the creation of valuable secondary raw materials.