plastic recycling grinder

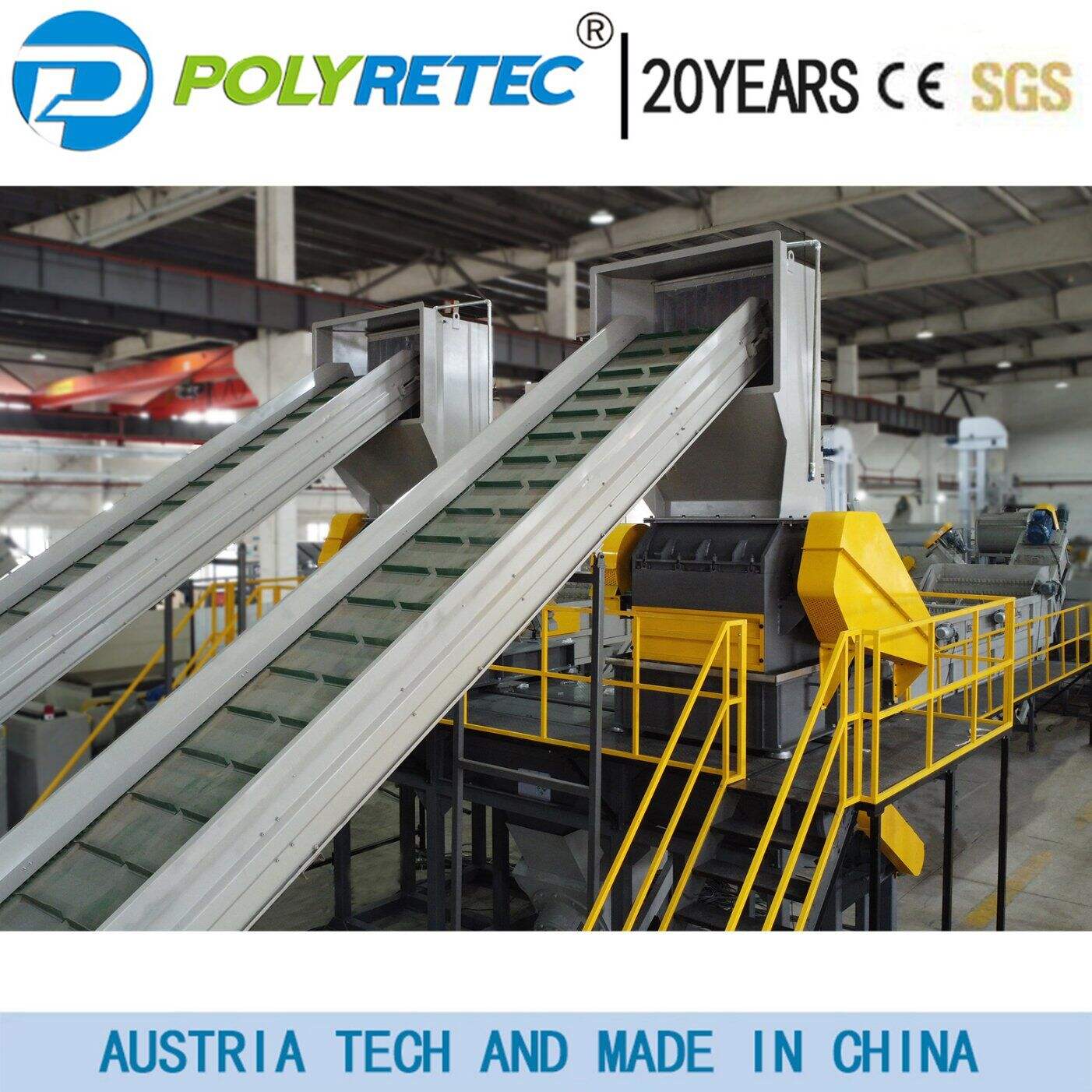

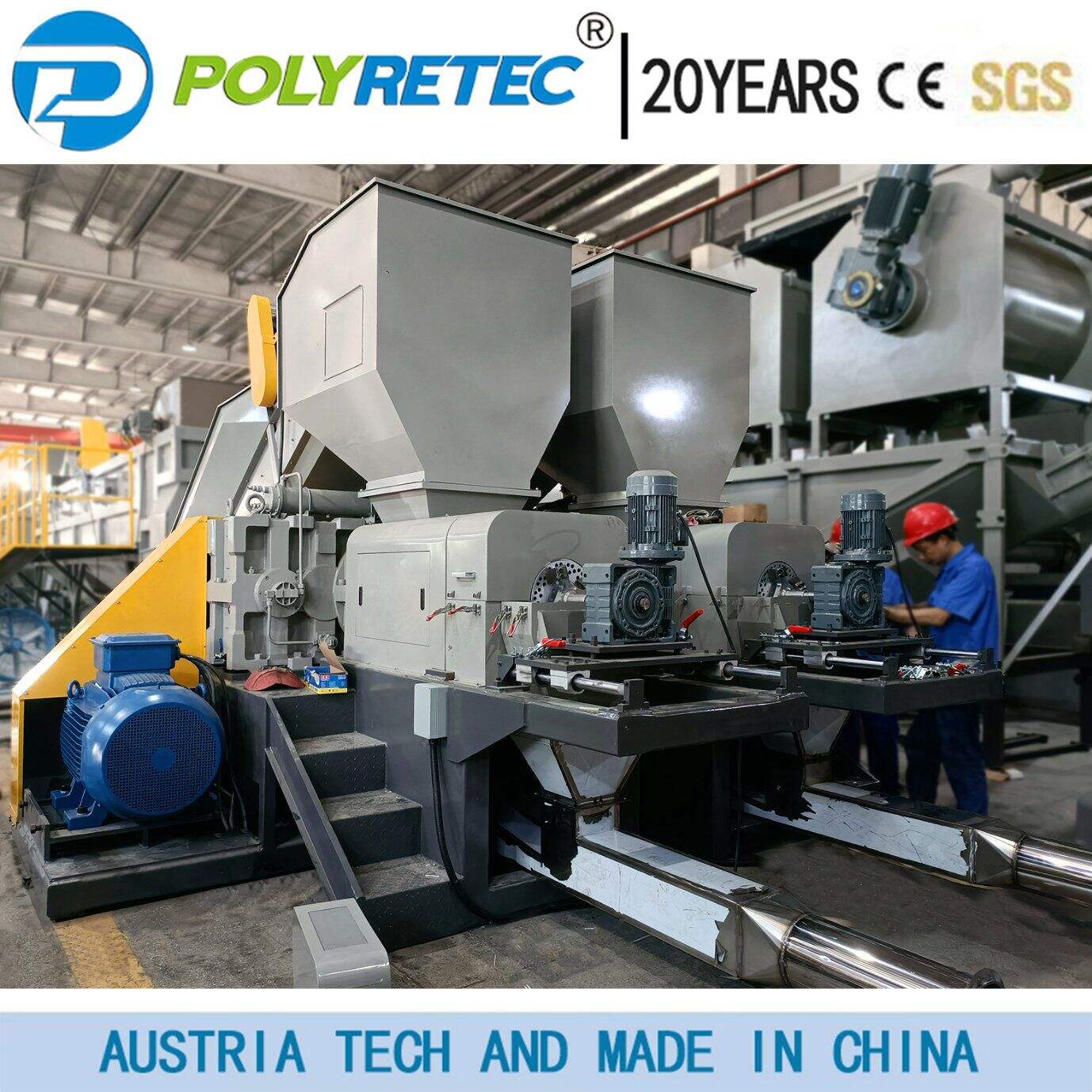

The plastic recycling grinder is an essential piece of equipment in modern recycling operations, designed to efficiently process various types of plastic waste into recyclable materials. This industrial-grade machine features hardened steel blades that rotate at high speeds, effectively reducing plastic items into uniform, small-sized particles. The grinder's robust construction includes a spacious feeding hopper, allowing for continuous material processing, while its advanced blade configuration ensures consistent particle size output. The machine incorporates sophisticated safety mechanisms, including emergency stop systems and overload protection, ensuring operator safety and equipment longevity. Its versatile design accommodates different plastic types, from PET bottles to industrial scraps, making it suitable for both small recycling facilities and large-scale industrial operations. The grinder's precision-engineered cutting chamber minimizes heat generation during operation, preserving the material's physical properties and ensuring high-quality output. Additionally, the system features adjustable grinding parameters, allowing operators to customize the final particle size according to specific requirements. The machine's efficient design also includes dust collection systems and noise reduction features, making it environmentally friendly and workplace-compatible.